crushing sieving efficiency

COLO3000S Powder Sieving Machine Operation Manual

tanks, etc. Drive unit is installed in the rear of the sieving machine, rotated by the motor through Vbelt, so that the screen box reciprocates. Through specific reciprocating rotary movement and slight tilt of the screen, the powder goes through the screen quickly, to achieve high sieving efficiency and high output.

Device for crushing and sieving grain

(57) Abstract: The inventive device for crushing and sieving grain contains bins for receiving and storing grain and product screens for the preparation of grain for milling, sieving, grinding systems, air and magnetic separators, the first and second screw conveyors with feeders and transport channels associated inputs, respectively, to the outputs of the Sith the preparation of grains and ...

ball mill sieving efficiency

FM 306: SIZE REDUCTION AND SIEVING. sieving. 2. Grind the sample in the ball mill for 30 minutes noting the energy consumed ... crushing efficiency as n wa ... mechanical efficiency.

Proppant Crush Cell w/ Piston Gilson Co. Gilson Co.

PRA14 Proppant Crush Cell w/Piston has (89mm) outside is designed for use with the PR10 Proppant Crush Test System and other similar crush systems for testing proppants used in hydraulic fracturing for oil and gas recovery. The Cell holds the sample for measuring the proppant's resistance to crushing and degradation.

10 Differences Between Laser Diffraction and Sieving for ...

This article describes 10 differences between laser diffraction and sieving for particle size analysis. Smaller Sample In contrast to sieving methods, laser diffraction needs just a small representative sample, but it can also be used with a larger sample.

Vibrating screen|Vibrating screens|Round vibrating screen ...

high frequency, small amplitude, high efficiency. efficiency, large capacity, the moisture content of the material requirements low. eccentric block .

Design Analysis of a Reciprocating Cassava Sieving Machine

sieving tray. The machine was tested and confirmed to have an output capacity of /hr and an efficiency of %, which makes it very adequate and capable for mass production. Keywords: Reciprocating, Cassava, Sieving Machine I. Introduction

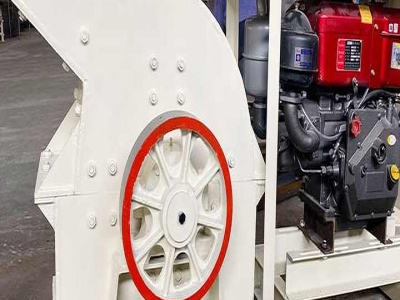

high efficiency stone crushing machine line

Highefficiency Equipment forArgillite Crushing Processing. Highefficiency ArgilliteCrushing Machine. In the argillite processing line, argillite crushing machine performs as the core mining machine, it plays an important role in the processing line. As for argillite crushing machine, it refers to the crushing equipment used for turning large argillite into small particles.

Primary Used Sand Reclamation Process Efficiency

crushing and sieving process in dependence of the overheating degree of the reference sand samples (100°, 200°, and 300°C) were investigated at various table vibration frequencies and feed loads of the sieve set. The relative index of the crushing ability was determined.

Crushing Buckets Sieving Buckets: What Suits Your Needs ...

Oct 19, 2017· Finding the correct crushing bucket or sieving bucket for the job is important. Failure to do so can result in reduced productivity and reduced profit as a result. What is a crushing bucket? Crushing buckets are used in a range of industries for biowaste, mixed .

HighEfficiency Sand Making Equipment for Trachyte ...

Trachyte crushing processingis one of the most important links which has a vital role in the production process of the material. Looking for a professional partner and choosing highefficiency sand making machine can provide great help for your trachyte deep processing.

Measure the efficiency sieve

how to calculate crushing efficiency ... Home/Product/measure the efficiency sieve. measure the efficiency sieve. Mechanical Analysis of Soil University of Memphis. Mechanical Analysis of Soil Sieve analysis Hydrometer analysis CIVL 1101 Sieve Analysis 1/7. Sieve Analysis Sieve analysis consists of shaking the soil sample ...

THE IMPROVEMENT OF THE EFFICIENCY OF AN .

primary crushing stage produced higher grinding efficiency in the circuit and should be incorporated into an aluminosilicate plant grinding system. The results also showed the difficulty in operating a crushing plant that treats different raw materials. In general hard materials like .

Washed Stone Sieving Machine

The drumtype washing equipment washed stone sieving machine equipment industry is an important raw material and energy production, its efficiency will .

Device for crushing and sieving grain

The estimated performance of the device for crushing and sieving grain is 100140 kg/h In Fig. 1 shows a device for crushing and sieving of grain, General view; Fig. 2 kinematic diagram of the device of Fig. 3 the first feeder; Fig. 4 channel transport with the possibility of a possible separation; Fig. 5 return channel with magnetic separation and the second feeder.

Latest Posts

- عملية الطحن نيبال للبيع

- سحق الفحم في التعدين الأسترالي

- معدات التعدين الشركات المصنعة في المملكة العربية السعودية

- مصنع لتجهيز الجبس للبيع في امريكا

- إيداع الحجر السماقي النحاس

- الحجر كسارة المطرقة مصر الصين

- صورة عالية الجودة لمحطة التكسير المخروطية

- الرخام الصناعي آلة كسارة

- شبكة الباريت مصنع لتجهيز

- مواد البناء كسارة الحجر

- مصنعي الكسارات الحجرية في جنوب المملكة العربية السعودية

- آلة طحن 2500 شبكة سعر الجهاز

- مزايا وعيوب التعدين المنغنيز

- التلقائي كسارة حجر

- شركة تصنيع آلات البناء

- harga mesin grinding crankshaft china

- canada ore ball mill

- china stone crushers in brazil

- quarry eye shadow

- campco wikipedia the free encyclopedia

- crusheing equipments and mills jan

- digunakan pabrik salep untuk dijual

- milling machine 3000mm

- iron mines in saudi arabia

- berapa biaya batu crusher di kenya

- soil conveyor systems

- hop baleers for sale

- hammer mill efficiancy calculation

- mesin crusher pe750 1060 jul

- coal pulverizer manufacturer in chennai