sintering ore furnace

Sintering Furnaces | CAD/CAM | Dental Lab | Schütz Dental

The furnaces are manufactured in Germany with highquality parts and materials. They will help you sinter your dental restorations safely and to a precise fit. All three Tizian Sintering Furnaces are freely programmable and thus offer you the opportunity to sinter different zirconium dioxide materials.

Dental Sintering Furnaces | Imagine USA

Imagine, a dental milling center, offers complete solutions to navigating the digital dental landscape. Our diverse selection of affordably priced and premium CAD/CAM solutions focused on implantology, we provide the most advanced equipment, software, .

sintering of very fine iron ore

sintering of very fine iron ore phfn. Modeling Sintering Process of Iron Ore,. treating the very fine ore that will . sintered ore by sintering . what iron ore crusher for sinter fines Deze pagina vertalen. sintering of very fine iron ore sintering and pelletisation of indian iron ores. sintering and pelletisation of indian iron ores by suresh kumar* amp; srinivasan .

Effect of Recycling Blast Furnace Flue Dust as Pellets on ...

ElHussiny et al./Science of Sintering, 42 (2010) 269281 271 88 80 72 64 56 48 40 32 24 16 8 a=Hematite b=FeO(OH) a b a a ab a a a a a a a a a a a a a a a 2Theta Chemical composition of main components of raw materials Components Iron Ore, % Blast furnace flue dust,

Vacuum MIM Sintering Furnaces

Vacuum Furnace Requirements for MIM Industry An important factor for a costefficient operation of vacuum MIM furnaces is the economical consumption of process gas and electrical power. Depending on the gas type, those two elements of the sintering process can .

iron sintering ore

Life Cycle Assessment of Iron Ore Sintering Process ScienceDirect. Iron ore sintering is an energyintensive process associated with emission of pollutants in iron and steel industry. In order to comprehensively evaluate the environmental impacts of sintering, a detailed life cycle assessment of a sintering plant was conducted.

iron ore sintering for blast furnace

Laboratory iron ore sintering studies. 1. Process ... Iron ore sintering is the most popular process used to produce a suitable feed for the blast furnace. With changing iron ore supplies and composition, steel mills have to continually adjust the blended ore mix composition to the sinter plant. To help decision making in this area, and also

UTILIZATION OF WASTE POWDER AND SLUDGE IN IRON .

Sintering of the iron ore containing materials is required to obtain a product, whose treatment allows regular and intensive stock of the blast furnaces. Iron ores concentrates and waste iron containing powders are subjected to advanced sintering [13]. An important and durable trend at advance preparation of the raw

Thermal Technology High Temperature Furnaces

Thermal technology has a 70+ year history in the advanced thermal processing marketplace as a pioneer in the hightemperature vacuum furnace industry. With over 3,000 installations worldwide across a range of different industries, our products can be fully customized to suit your unique thermal processing needs.

pellet furnace iron ore sintering

1990 Fundamental study of pore formation in iron ore . overall, lump and pellets are used in proportions of 1:2:1 in blast furnace burdens [14]. Sintering process Sintering of iron ore is a process [5,6,8] in which air is drawn down through a bed of raw mixture of iron ore, limestone, coke and other minor additives.

sintering furnace China HS code import tariff for ...

Latest China HS Code tariff for sintering furnace Tariff duty, regulations restrictions, landed cost calculator, customs data for sintering furnace in ETCN. China customs statistics trade data.

iron ore sinter making

The Sintering Process of Iron Ore Fines | The process of sintering is basically a pretreatment process step during iron making to produce charge material called sinter for the blast furnace from iron ore fines and also from metallurgical wastes .

an issue with the sintering furnace | Dental Lab Network

Sep 13, 2014· The length and diameter have large influence on behavior. No Two furnace are exact same in my experience having owned over 50 furnaces for sintering of many many sizes. For our small furnace that we sell, we have close to Max. (95110) For our Largest furnace, we reduce OPh to around 55. The info on back of furnace is just a close guess.

Dental Furnace (CDF) for sintering processes Carbolite Gero

An interruption to the sintering process, for example by a power failure, is displayed by the programmer. This ensures that the sintering process of the dental furnace is completed correctly and the crowns and frameworks have the desired density and stability. The dental furnace is supplied complete with sintering tray and support beads.

Sintering Vacuum Furnace For Cleaning Breaker Plates

china iron ore sintering systems ... Oven/ Vacuum Sintering Furnace,Vacuum Heat Treatment Furnace,Vacuum fiber with excellent thermal insulation;Vacuum Reservoir with water cooling system. . high temperature heat treatment electric furnace manufacturer in China, we have heat treatment furnace vacuum heat treatment ...

Study of sinter reactions when fine iron ore is replaced ...

The effect of replacing fine ore by coarse ore on sintering reactions was investigated using an infrared furnace on laboratory scale and sinter pots on pilot plant scale. Five sinter mixes were prepared by changing the percentage coarse ore from 0% to 100% in 25% increments.

A cutting edge new sintering furnace for zirconia | Dental ...

Jul 14, 2015· A cutting edge new sintering furnace for zirconia Zubler USA's new VARIO S400 offers speed and quality. July 14, 2015. Zubler USA has announced the VARIO S400 Sintering oven is now available. The furnace is the result the CAD/CAM enginee?ring expertise of Dental Concept Systems combined with the experienced furnace engineers at Zubler in Germany.

VMP vacuum mechanical pressure sintering furnace .

A vacuum hot pressing sintering furnace comprises a sintering furnace and a vacuuming part, the sintering furnace comprises a furnace body and a heating chamber installed in the furnace body, wherein the sintering furnace is provided with six conductive electrodes, wherein the lower side of the upper furnace body is respectively The upper beam of the hydraulic machine and the lower beam .

SINTERING FURNACES

sintering furnace Sinterofen 300S sintering furnace Zirkonofen 700 sintering furnace Zirkonofen 600/V2 sintering furnace NEW! Zirkonofen Turbo sintering furnace Accessories Zirkonofen 600/V3 sintering furnace. 4 5 12 USB TECHNICAL DATA Size (W x .

Air Leak Detection in Sintering Furnaces to Enhance ...

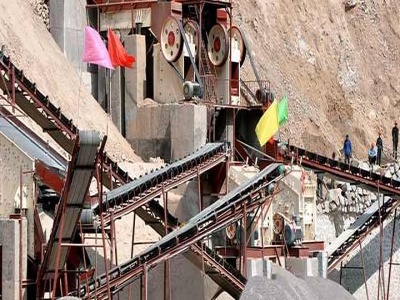

A sintering furnace mixes powdered ore with auxiliary materials such as powdered coke and sinters them to make lump ore, which is used as a raw material in blast furnaces. Since modern blast furnaces are large and require sophisticated and efficient operation, stringent control of the quality (lump size) of the sintered ore is essential.

sintering ore furnace

A sintering furnace mixes powdered ore with auxiliary materials such as powdered coke and sinters them to make lump ore, which is used as a raw material in blast furnaces. Since modern blast furnaces are large and require sophisticated and efficient operation, stringent control of the quality (lump size) of the sintered ore is essential.

Blast Furnace Charge (Raw Materials for ...

Jan 11, 2013· Fluxes are added to sinter or charged directly into the blast furnace in order to liquefy ore and sinter gangue and fuel ash, converting them to free flowing slag that can be run of the furnace. The flux is decided by the gangue and ash analysis. The limestone is the most popular flux in blast furnace and sintering process.

iron ore sintering for blast furnace

Iron Ore Mineral Fact Sheets Australian Mines Atlas. Sintering is a process used to agglomerate iron ore fines in preparation for blastfurnace smelting, and is usually carried out at .

sintering siderite ore

Ore Mining Process Sintering . sintering ore furnace thegurukulinstitute. Ironore SInterIng ProceSS oPtImIzatIon. The sintering mixture, necessary for iron ore sinter production, is composed of various kinds of iron ores, . into skip bins at the blast furnace. Read More

Latest Posts

- كسارة مخروطية في جنوب آسيا

- راتب عمال محجر الرخام العماني

- حزام سلسلة مدفوعة الصين

- كسارة حجر الجرانيت والكلي

- مقلع حجر للإيجار في الجزائر

- آلة محطم لالمجاميع

- محطم دبي للبيع

- صناعة البناء في الجزائر وصناعتها

- مخطط تدفق خام كسارة حصاة الحديد

- خطة غسيل مركز خام الحديد في مصر

- سعر الحزام العلامات التجارية القارية

- آلة تكسير خام النحاس psgb

- آلة ميكانيكية من عمان

- أداة طحن حبة حبة

- اسعار مصنع الرمل للبيع

- vibrating screens from zenith of china

- buy a small roll mill in canada gnexid org

- artistika quarry tile jakarta

- mesin bijih crusher emas dalam penjualan malaysia

- smart structure impact crusher

- high capacity impact mobile jaw crusher

- restate the problem related to impact crusher html

- blok bore up jupiter z cc

- grinding sizing mini

- waxi china stst mills

- gold mining process ghana

- rock to sand machine for sale

- grinding machine for groundnuts

- stone roller millstone

- coal face equipment crusher