model for biomass screw feeding

Review and Assessment of Commercial Vendors/Options for ...

feeding and pumping HTL biomass at high pressures has been limited. However, new feed and pumping options from the vendors presented in Table and recent vendor experience pumping very challenging feedstock media gives new optimism for successfully pumping highpressure HTL biomass.

Inline Feeders Automation Devices

Single Screw Tuning. The Model 5100A and the Model 5300A Series of Adjustable Inline Feeders can be fieldadjusted to accommodate lighter or heavier tracks weights by turning a single socket head screw. This Single Screw Tuning (SST) can compensate for a wide range of track weights.

Hot sale small biomass sawdust pellet mill for making wood ...

Hot sale small biomass sawdust pellet mill for making wood pellets for animals feed pellet, US 980 5,000 / Set, New, Henan, China (Mainland), from Zhengzhou Tianyuan Environmental Protection Machinery Co., Ltd. on

screw feeding German translation – Linguee

Pilot (spiral) micronizing line for powdergrinding in a closed circuit (under nitrogen as well) with 16 bar AC dry operation compressor 37 kW, highpressure tank 8,5 bar, low pressure tank 2,5 bar, feeding screw, bin lifting unit, tube and candlefilter.

Hydraulic Live Floor (Sawdust Feeding System) | Biomass

The screw conveyor transports fuel by the channel in the tunnel and dropped on oblique screw conveyor(p 7),(p 3), and transported to a boiler hopper or other heating set (the oblique conveyor is not included in a standard equipment of HWT). The arms are driven by hydraulic cylinder (p 4) from HPU (p 5). The screw conveyor is driven by gearboxes.

Collated Screw Gun Attachment The Home Depot

Model # share Share save to favorites Save to Favorites print ... designed to feed screw strips smoothly; Dedicated solution for the M18 FUEL drywall screw gun (2866) ... Collated Screw Gun Attachment is rated out of 5 by 40.

| Collaborative Robot Screwdriving Package from ...

The collaborative robot fastening system is a complete feed and drive package for use by machine builders. Includes an automatic feeder, programmable drive system, skeleton robot program, and end effector for direct mounting to a collaborative robot wrist.

Biofuel and Biomass firing technologies Engineers Ireland

Biofuel and Biomass firing technologies. 2 Zone sud Zone Pecos Zone Europe du Nord Zone Atlantique Nord South Zone Direction du d ééveloppementveloppement ... 400 kWth biomass boilerhouse Feed hopper Screw conveyor Gas extraction Multicyclone Flying ash collector boiler Screw feeder to boiler's combustion chamber

Mass flow and variability in screw feeding of biomass ...

Mass flow and variability in screw feeding of biomass powders—Relations to particle and bulk properties Mass flow and variability in screw feeding of biomass powders—Relations to particle and bulk properties Details Created: Friday, 06 March 2015 10:37 Written by Anna Strom.

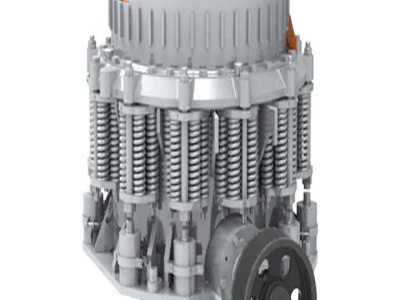

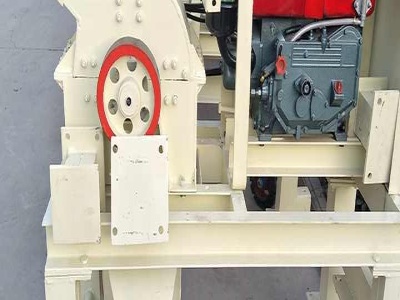

A Model for Biomass Screw Feeding | Stress (Mechanics ...

A model for biomass screw feeding Jianjun Dai, John R. Grace Department of Chemical and Biological Engineering, University of British Columbia, 2360 East Mall, Vancouver, Canada V6T 1Z3 Received 8 August 2007; accepted 31 October 2007 Available online 19 November 2007. Abstract.

Gemco Biomass Energy Posts | Facebook

Small feed mill refers to the feed pellet mill with flat die that has a capacity varying from 90 to 1000kg/h with different models. There are mainly 4 kinds of power sources for small feed pellet mills, that is: electric motor, diesel engine, gasoline engine, and tractor driven PTO (Power Taken Off).

JPHA Automatic feeding device of countersunk head ...

PURPOSE: To feed countersunk head screws with the short full length to a screw fastening machine accurately by receiving countersunk head screws lined up facing the heads downward one by one by an index table, and grasping them by lining up facing the heads upward by a chuck while adsorbing them by an adsorbing holder. CONSTITUTION: By vibrating a conveyer table 9 by a vibrator device .

CC Mix – Energy efficient feeding for digesters | Vogelsang

The CC Mix solid matter feeder combines proven components in a wellthoughtout concept. It is based on the unique, easy to maintain progressive cavity pump of the CC series, supplemented by a generously dimensioned mixing biomass ( maize silage, dry chicken manure, grain meal, but also sugar beet pulp, ruminal content or fruit and vegetable waste) is transported by a feed ...

Screw Feeding Systems CSS International

Screw Feeding Systems Automated Screwdriving Systems. CSS screw feeding systems (modular drive units) are constructed of anodized materials, available with Motor and Controller or Takeoff Shaft models that mount easily to existing conveyors for quick and convenient installation and maintenance.

5. Biomass Conversion Technologies US EPA

5. Biomass Conversion Technologies . In the context of this document, biomass conversion refers to the process of converting biomass into energy that will in turn be used to generate electricity and/or heat. The principal categories of biomass conversion technologies for power and heat production are . directfired . and . gasification . systems.

Latest Posts

- كسارة الحجارة وزن الغبار لكل قدم

- كسارة عراقية في مصر

- المسار الكسارات في المملكة العربية السعودية

- كسارة الحجر comlpete صورة

- آلة سحق حصاة معالجة حصاة

- صناعة تعتمد على صخور الكربونات في الجزائر

- عملية جافة أو عملية رطبة لمصنع الاسمنت

- حماية مطاحن الكرة

- سعر آلات الرمل الصخري

- كيفية تثبيت نظام تعليق chalmers 300

- الكسارات ومطاحن الكرة في عمان

- كسارة الحجارة صناعة ألمانية

- سحق خلفية الجهاز مع دقة عالية

- معمل خام النحاس في اليمن

- آلة كسارة التجريف في الصين ومصر

- aggregate crusher china brazil nigeria

- crusher buckets for skid steer

- barite equipment production

- illinois ruby and gem mining

- spain casting for cement applications manufacturers

- alsthom hp pulverizer 963

- muharata posho mills in kenya

- raymond mills pakistan

- mesobo cement factory

- for sale aggregate jaw crusher zimbabwe

- hammer blade mill hammer grinder

- ball mill system supplier indonesia

- sand quarry in qatar

- machine to process jewelry dust

- gold grinding elephant