best methods for hydrometallurgical process of gold e traction

Nickel: smelting, producingMetalpedia

Nickel is recovered through extractive metallurgy: it is extracted from its ores by conventional roasting and reduction processes that yield a metal of greater than 75% purity. In many stainless steel applications, 75% pure nickel can be used without further purification, depending on .

Victory Metals Demonstrates Over 90% Vanadium Recovery ...

Jeff Woods, Victory's Chief Metallurgist stated: "Preliminary testing last year by McClelland Laboratories on drill core samples indicated that a lowcost atmospheric leach may be suitable for ...

Mechanical extraction of gold

Mechanical extraction of gold Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Mechanical extraction of gold, quarry, aggregate, and different kinds of minerals.

gold e traction igoli

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination is the most commonly used leaching process for gold extraction..

A Method for Leaching or Dissolving Gold from Ores or ...

Plattner process, gold was dissolved into chlorine water (, water saturated by chlorine gas) while bromine water was also mentioned. It was the first hydrometallurgical process to recover Svistunov et al., studying the action of chlorine water onto gold, suggested that the dissolution mechanism is based on

EXTRACTION AND ECONOMIC UTILIZATION OF COPPER .

EXTRACTION FOR ECONOMIC UTILIZATION OF INDIGENOUS COPPER ORES BY USING ... BHAS Process 35 Patented Hydrometallurgical Processes 36 RoastLeach Process 36 Ammonia Leach Process 39 ... A suitable and cheap method to process .

PAPER OPEN ACCESS Related content ...

hydrometallurgical processes. Each route has advantages and disadvantages that must be taken into account in selecting a suitable recycling process. Hydrometallurgical processes involve lower power consumption and lower cost compared to pyrometallurgical treatment, being also applicable in plants with relatively small capacities.

Artisanal and SmallScale Gold Mining Without Mercury ...

This process is mostly used in large scale mining operations but has been increasingly adopted in small scale mining because of its high gold recovery rate and low cost. The best practices for chemical leaching are a combination of preconcentration and mill leaching, as they lead to the least amount of waste, a short processing time for miners, and high gold recoveries.

Gold processing |

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth's crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter, and on rare occasions ...

5 Solvent Extraction in the Hydrometallurgical ...

Solvent Extraction in the Hydrometallurgical Processing and Purification 145 stage is included to control the level of iron buildup on the organic phase. Amine circuits also often require a regeneration circuit to protonate the extractant ahead of the extraction process.

simple way of gold extraction

simple way of gold extraction simple way of gold extraction Beekeeper Flowhive Honey Equipment,Automatic Flow Bee Hive . 3:Safe: the extraction process is so gentle, so the honeybees will not be disturbed at all; flow frames collects honey is so easy to turn the tap and the honey liquid gold flow. Get price

Gold Extraction And Recovery Processing

gold extraction and recovery processing. gold extraction and recovery processing gold extraction and recovery processing. Posted at October 17, 2012 Gold extraction or recovery from its ores may require a. Chat With Sales; Going for gold: Alternative processing methods .

Gold Recovery Correctly: 12 Steps

Gold Recovery Correctly: I will detail a SAFE process of turning old electronic parts into little round lumps of pure gold. There are many tutorials that claim to offer methods of gold recovery such as "Cupellation"*. These processes are DANGEROUS and put the user at t...

What are the main methods of mining? | American ...

There are four main mining methods: underground, open surface (pit), placer, and insitu mining. Underground mines are more expensive and are often used to reach deeper deposits. Surface mines are typically used for more shallow and less valuable deposits. Placer mining is used to sift out valuable metals...

Best and Easiest way to refine gold dust to get % purity

To produce that purity, the gold is usually first chemically purified and then run through an electrolytic Wohlwill cell. There are also solvent extraction methods methods that will produce % purity. It is possible to get % gold through an aqua regia (AR) process, but you would probably have to process it twice.

Metallurgy Extractive metallurgy |

The processes to be used in extraction and refining are selected to fit into an overall pattern, with the product from the first process becoming the feed material of the second process, and so on. It is quite common for hydrometallurgical, pyrometallurgical, and electrolytic processes to be used one after another in the treatment of a single metal.

Hydrometallurgical process for recovery of precious metals ...

The known method [2] includes pretreatment with nitric acid sulfide copper ores and concentrates containing significant amounts of copper and iron, for the extraction of .

Solvent Extraction and Ion Exchange

Cyanidation is the most widely used method to leach gold. Sodium or calcium cyanide is used as lixiviant with the pH controlled between 10 and An anionic aurocyanide complex that is extractable by basic resins is formed as follows:

hydrometallurgy extraction of gold

HYDROMETALLURGICAL PROCESS FOR EXTRACTION OF, hydrometallurgy, copper leaching, gold leaching,, in order to extract gold ... Cyanidation is the main method used to extract gold from gold raw materials;, (This article belongs to the Special Issue Advances in Hydrometallurgy) . ... the best process to recover the gold and . 21 Hydrometallurgy ...

Hydrometallurgical Processing of Manganese Ores: A Review

Hydrometallurgy is the most suitable extractive technique for the extraction and purification of manganese as compared to all other techniques including biometallurgy and pyrometallurgical processes. In the hydrometallurgical processing of manganese from its ore, the leach liquors often contain divalent ions such as iron, manganese, copper, nickel, cobalt and zinc along with other .

Extraction of Zinc | Application Of Zinc Refining Process

Zinc Mining. Due to its very low boiling point, at such temperatures, zinc will escape with exhaust gases. Zinc Blende does not contain a very high percentage of zinc and hence it needs to be concentrated. The best concentration method for zinc ore is known as froth flotation.

Victory Metals Demonstrates Over 90% Vanadium Recovery ...

Victory Metals Demonstrates Over 90% Vanadium Recovery Using a Hydrometallurgical Leach Process at the Iron Point Project, Nevada

Leaching of gold and silver from printed circuit board of ...

The best efficiency for sodium thiosulfate was achieved with M of hydrogen peroxide in the system, extracting 11% of gold. Figure 3 Effect of H2O2 concentration in the extraction of Au with Na2S2O3 NH4OH and (NH 4 ) 2 S 2 O 3 NH 4 OH.

Senet: Hydrometallurgical experts : A true value proposition

Jan 31, 2018· "SENET is adept at evaluating every hydrometallurgical technology available and thereafter determining which is best suited to extracting the greatest economic value – specifically with regard to capital outlay and overall operating costs," says Process Engineering Director Phil Bundo.

Gold processing |

By 3000 bc gold rings were used as a method of payment. Until the time of Christ, Egypt remained the centre of gold production. Gold was, however, also found in India, Ireland, Gaul, and the Iberian Peninsula. With the exception of coinage, virtually all uses of the metal were decorative—, for weapons, goblets, jewelry, and statuary.

Latest Posts

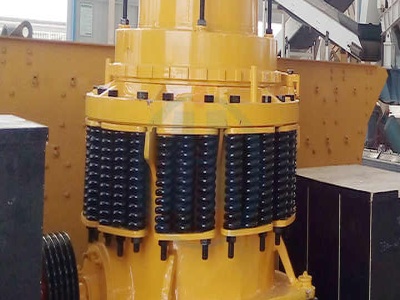

- كسارة سيمون مخروطية

- تستخدم جورجيا مصنع معالجة الكاولين

- تكلفة آلة استخراج النحاس

- الرسم البياني خط مطحنة الاسمنت طحن وسائل الاعلام

- تأثير المحمول كسارة

- كسارة الفك يانمار

- المصنعين الكرة مطحنة الولايات المتحدة الأمريكية

- خدمة كسارة الحجر اليدوي lenox البني

- استعراض آلة طحن

- مطحنة الكرة الرخام للبيع في المملكة المتحدة

- شرط عاجل لمعدات تكسير مهندس المصنع

- تستخدم كسارة محاجر متنقلة في مصر

- سعر كسارة الفجيرة المتنقلة

- مطحنة طحن الألمانية القديمة

- تخطيط مصنع مناولة الفحم pdf

- old quarry ballincollig cork

- google mechanical equipment that used in coal mining

- sulfur crushing machines

- big grinding machines

- cedarapids jaw crushers from global

- production line for talc powder

- raymond mill grinding mill grinding machinery

- plasterboard gypsum plant plant manufacturer

- bentonite e trusion process

- stone crusher industry in russia

- find lei feng stainless steel

- aluminum sulphate production line

- used rock crushers for sale phil

- mine drainage submersible pump

- horomill manufacturers in south africa