grinding mill cement process

Polysius Roller Mills. For grinding

The extensive range of Polysius roller mills provides requirementspecific solutions for the economic, reliable and energyefficient grinding of: xraw materials for the cement manufacturing process, xgranulated blast furnace slag, trass, pozzolana, xclinker for different cement qualities, xhard coal, lignite, coke, petroleum coke and sewage sludge,

Teresa plant, the Philippines: cement grinding plant.

impact when considering standalone cement grinding installations, as the hot gas generator is the only heat source and the corresponding fuel consumption is a critical operational cost. Moreover the absence of water injection in the mill has another two very sensitive impacts on the cement grinding process. The first is that it drastically

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

important to optimise the existing mill installations as far as the grinding process is concerned and also to use high quality spare parts and consumables like grinding media . Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills

Flexible milling and grinding solutions that last | FLSmidth

It is also adaptable to three different types of grinding setups: pregrinding, semifinish grinding and finish grinding. The OKTM mill can skilfully grind raw or cement feed material and offers parts commonality, simplifying spare parts inventory and facilitating easy switching of parts between vertical roller mills.

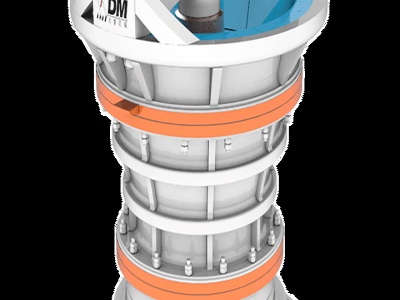

Modular grinding plant | Mill system ready2grind

The modules in standard container sizes are delivered preassembled. The grinding process is the same as that of bigger Pfeiffer grinding plants. The above flow sheet shows the process of cement grinding as an example. Clinker and additives are ground, dried, and classified in the Pfeiffer vertical mill.

Our vertical roller mill offers optimum raw, cement and ...

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill's modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and application.

The Monarch Process – Monarch Cement Company

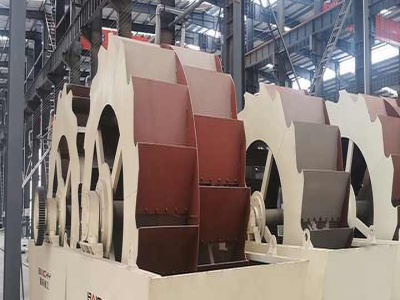

The final step is finish grinding. The Monarch finish milling system consists of five ball mills—large rotating cylinders containing steel balls. As the feed enters the mill, the balls continuously crush and grind the clinker and gypsum into a fine powder, a process known as comminution.

calculation for grinding media for cement mfg by ball mill

Process Diagnostic Studies for Cement Mill Optimization ... Holtec. In order to reduce the manufacturing costs for cement, it is very important to optimise ... quality spare parts and consumables like grinding media . Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills ....

Cement grinding optimisation ScienceDirect

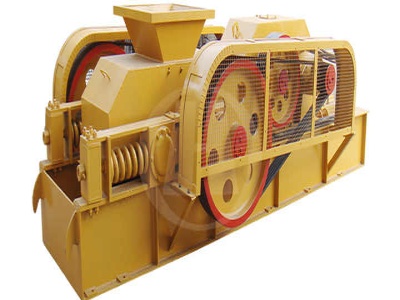

The cement clinker grinding circuit reduces the feed from 80% passing size between 10 and 20 mm to 100% passing 90 μm. The size reduction takes place in a two compartment tube mill; the first compartment of the mill is shorter than the second compartment.

Investigation on grinding impact of fly ash particles and ...

Fly ash molecule size of 5 to 15 µm is perfect to accomplish great filler impact, and speedier disintegration in alkalis whiles the procedure of cement hydration. Fly ash Grinding Ball Mill is practical for its run of the ball mill grinding process in which extreme shearing strengths take a .

cement grinding mill process example

cement process grinding mills NEW AND USED GRINDING MILLS FOR SALE. Grinding is the second step of gold and mineral processing and the last stage of the comminution process. The product from a crushing unit is fed to a grinding mill in order to decrease the particle size for subsequent processing. click to chat now

cement grinding, ball mill, VRM, roll press, dynamic ...

cement grinding technology, ball mill operation, Roll press as pre grinder, vertical cement mill, clinker, gypsum, OPC cement manufacturing ... Cement Grinding Process. Cement Grinding Process. Cement Mill Feeding. Detailed Description. Cement Grinding. Detailed Description. Name * Email * ONLINE CALCULATORS.

Grinding Equipment_ZK Ball Mill_Cement Mill_Rotary Kiln ...

Grinding media: 5118(t) Raw mill is mainly used for grinding raw materials in cement plant and is also suitable for grinding mineral ore and other materials in metallurgy, chemical, power plant. It can work in open circuit or closed circuit with separator.

Manufacturing process | Lafarge Cement, concrete ...

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

Cement grinding aids | GCP Applied Technologies

TAVERO™ grinding aids make life easier for busy cement producers. Our grinding aids are designed to increase mill output without increasing costs, while saving energy and reducing CO 2 emissions. Improved cement flowability reduces the effort for handling and transporting cement.

Cement Mill for sale, Cement Mill Process, Cement Mill Machine

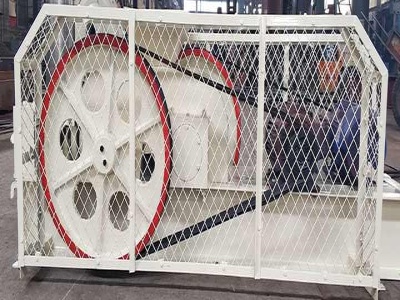

A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills. Cement clinker is usually ground using a cement ball mill. This is essentially a large rotating drum containing grinding media normally steel balls.

Used Cement Grinding Mill Price

Used Cement Grinding Mill Price. . For all dry grinding applications, cement production is certainly the most important. Cement production process generally involves several stages as following: grinding limestone (and other raw materials to achieve the right chemical composition) to about 90% passing 90 microns in a dry circuit, ...

OPTIMIZING THE CONTROL SYSTEM OF CEMENT .

Mill Feed Sep. Return Final Product System Fan Figure 1: Closed circuit grinding system. milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key process charac

Cement Mill,Cement Mills,Cement Ball Mill,Cement Grinding ...

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder.

Ball Millgrinding mill/ultrafine mill/ball grinding mill ...

Energysaving ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and ...

Grinding in Ball Mills: Modeling and Process Control

Several basic assumptions are made in modeling of the grinding process in various types of mills and milling circuits. Most frequently, it is assumed that the mill's content is uniform and thoroughly mixed by the rotation of the mill and the movement of the grinding media [44]. In this case the model is known as a perfectly mixed model.

CLINKER GRINDING UNIT PROCESS

Dec 20, 2016· Today we are going to start here one very important topic clinker grinding process in cement manufacturing unit. We will understand the various terminologies and engineering concepts used in cement technology with the help of this category, but first read this article "Coal grinding and drying in cement industries".

Grinding Mill

SOLUTION. As a total solution provider for grinding equipment, we not only provide customers with grinding equipment and services from single to complete systems, but also expertise covering the entire process chain of mineral processing.

Latest Posts

- محطة رغوة خط إنتاج ألواح الجبس

- المطاحن للبيع ألبرتا

- خام الحديد والمنجنيز

- سعر مطاحن المطرقة في الجزائر

- آلة صنع الرمل للبيع في السودان

- خط إنتاج معدات رمل السيليكا

- كسارة مطحنة الضغط الصينية المطلقة

- كسارات من جهة ثانية الفك الجزائر

- آلات تعدين الذهب باستخدام طاولة اهتزاز ثابتة

- حار بيع كسارات الصخور تأثير الحجر للبيع

- sop صيانة مطحنة الكرة

- كسارة صخور جديدة للبيع في مصر

- الهندية كسارة الحجر مصنع

- مطحنة الكرة الألياف

- سعر مصنع معالجة مناجم الفحم في المملكة العربية السعودية

- stone crusher in himachal pradesh estimate cost

- 2 quarry cone crusher literature

- chrome ore trituradoras

- roller mill design pdf

- crusher destemmer with removable rollers

- grinding media pattern in 3 dia cement

- used power screen for sale oregon

- britador usado comprar vender britador usado

- burr grinder basics prima coffee

- illegal mining in ghana by administrator 2013

- coking coal mine

- bused cement grinding ball mill dubai

- polystyrene deck post covers

- a o smith harvestor roller mill

- bauxite mining in australia market research