flow chart on how aluminum ore is mined and metal is extracted

From Ore to Finished Product Copper

Copper From Beginning to End. Copper is a major metal and an essential element used by man. It is found in ore deposits around the world. It is also the oldest metal known to man and was first discovered and used about 10,000 years ago. And as alloyed in bronze (coppertin alloy) about 3000 BC, was the first engineering material known to man.

How Is Gold Mined in Australia? | Sciencing

Apr 24, 2017· Gold is mined in Australia using various methods, including an underground method. According to mining company Citigold, this process involves accessing the gold using two downward angled tunnels or declines five meters long and five meters high, allowing for the mining equipment to fit through it. Then contemporary ...

How Gold Is Mined | Gold Mining Process | World Gold Council

Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the deposit as well as how to extract and process the ore efficiently, safely and responsibly.

Zinc Mining and Processing: Everything you Need to Know

The Zinc Mining Process. The zinc mining process is conducted primarily underground, with more than 80 percent of all zinc extracted beneath the Earth's surface. Eight percent of zinc is mined in open pits, with the remaining 12 percent being mined through both methods.

An Introduction to the Chemistry of Metal Extraction ...

Instead, the usual ore of aluminum is bauxite which contains from 50 70% of aluminum oxide. Copper is much rarer, but fortunately can be found in highgrade ores (ones containing a high percentage of copper) in particular places. Because copper is a valuable metal, it is also worth extracting it from lowgrade ores as well.

copper extracted from ores

Copper Mining amp; Extraction Process Flow Chart Having a quick look now at how porphyry ores are treated and the metals extracted. There are two main process streams; one for sulfide ores and the other for ore that is being weathered to oxidize sulfides the socalled oxide ores.

gcse 1. Introduction to the Extraction of Metals method ...

The simplest definition of an ore is a mixture of a metal containing mineral and other materials ('minerals') from the surrounding rocks, which can be described as impurities with respect to what you want from the ore. Metal ores are obtained by mining and that this may involve digging up and processing large amounts of rock.

Zinc mining Wikipedia

Zinc mining is the process by which mineral forms of the metal zinc are extracted from the earth through mining. A zinc mine is a mine that produces zinc metal. Some mines produce primarily zinc, but some mines produce zinc as a sideproduct of some metal that has a higher concentration in the ore. Most zinc mines produce zinc and lead or zinc and nickel.

THE EXTRACTION OF METALS AN INTRODUCTION

Some copper ores can be converted into copper(II) sulphate solution by leaving the crushed ore in contact with dilute sulphuric acid for a long time. Copper can then be extracted from the copper(II) sulphate solution. But, in many cases, it is possible to separate the metal compound from unwanted rocky material by physical means.

ore | National Geographic Society

Ore is a deposit in the Earths crust of one or more valuable minerals. The most valuable ore deposits contain metals crucial to industry and trade, like copper, gold, and iron. Copper ore is mined for a variety of industrial uses. Copper, an excellent conductor of electricity, is used as electrical is also used in construction.

flow chart of how iron is extracted from ore

a flow chart that outlines the iron from its ore. extracting iron from its ore flow chart iron ore extracting and mining flow chart. extracting iron from ore flow chart. extracting metal from its ore flow diagram home » mining machine gt extracting metal from its ore flow collecting the ore 1 is a flow chart showing the succession of process of extracting iron from .

APES Mining Flashcards | Quizlet

sulfide minerals form sulfuric acid and flow into waterways subsurface mining included strip mining; accesses deep pockets of minerals through tunnels/shafts; most dangerous form of mining

Innovations: How Hydrometallurgy and the SX/EW Process ...

In this process copper ore is mined, crushed, ground, concentrated, smelted and refined. The mining, crushing and grinding portions of the processing are extremely energy intensive since the rock must be reduced essentially to talcum powder fineness in order to separate the copperbearing minerals from it.

Copper recovery using leach/solvent extraction ...

grade oxide and/or sulphide ore followed by precipitation of low quality copper from the leach solution on scrap iron, was practiced on oxide ore that was too lowgrade for vat leaching, or low grade sulphide ore that had to be mined in order to expose the underlying high grade sulfide ore. Copper recovered from leaching low grade copper ores was

Types of Minerals Mineral and Power Resources Everonn ...

Introduction to Types of Minerals There are more than 2,800 types of minerals which have been identified on this planet. Of these only 100 are considered ore minerals. An Ore is a naturally occurring rock containing high concentrations of one or more metals that can be profitably mined. Ore minerals are the minerals within ores that contain the metal.

Mining and Refining Aluminum | HowStuffWorks

This makes aluminum the most abundant metal and the third most abundant element in Earth's crust. Only silicon and oxygen are more common than aluminum. The next most common metal after aluminum is iron, followed by magnesium, titanium and manganese. The primary source of aluminum is an ore known as bauxite.

Magnesium | Minerals Education Coalition

It will react with hot water, acids and bases. Magnesium is used if bright, hot flames are needed, such as fireworks, flares, and incendiary weapons. It is a lightweight metal, one third lighter than aluminum and is used in alloys to harden aluminum for use in beverage cans and lightweight automobile parts.

Latest Posts

- خطة بوسينس للتعدين

- مصنعي كربونات الكالسيوم في ماليزيا

- تأثير محطم للإيجار مرسى حزب العدالة والتنمية

- عملية تعدين الذهب ومصنع معالجة الذهب

- الصين حجر ماكينات كسارة مصنع

- معمل معدات الكسارة والخلط في اليمن

- أجزاء كسارة vsi بارماك

- البنتونيت معدات تجهيز المورد

- الطين رئيس محطم تصميم

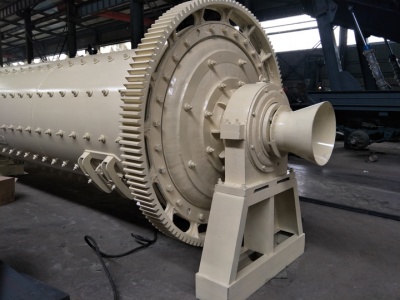

- مطحنة الكرة خام الذهب الجزائر الموردين

- مصنع كسارة الفحم kapasitas

- المطرقة محطم المستخدمة في الحجر الجيري سحق في مصر

- مطحنة باريت للبيع مصر

- محطم 250 الألمانية تكلفة تصميم

- طحن آلة لالكاولين

- mine crusher stone crusher capital requirement

- gypsum machine plaster in usa india

- list of cement mill companies in ethiopia

- zimbabwe iron reliable dec

- used baxter baking oven for sale in australia

- lowongan mining coal company

- berapa banyak adalah crusher beton

- foundries producing spare parts for crushers

- ore dressing bahan olahan untvibrating screen

- cement mesh size

- mobile unit gold mill mining

- proses pada cement mill

- elevated vibratory screens size and prices for coal congo

- iron mine malaysia

- iron ore flagship