ore concentrating solution

Iron ore – improving ore quality AusIMM Bulletin

Iron ore – improving ore quality. Adopting a solutionfocused approach to deliver value. Many iron ore producers are facing challenging times due to price uncertainty and the need to process crude material with increasing levels of impurities.

CH105: Lesson 4 Percentage Concentrations

The use of percentages is a common way of expressing the concentration of a solution. It is a straightforward approach that you have used earlier when dealing with the composition of compounds. There are, however, some differences. One is that the concentrations of solution are variable while the composition of compounds is constant.

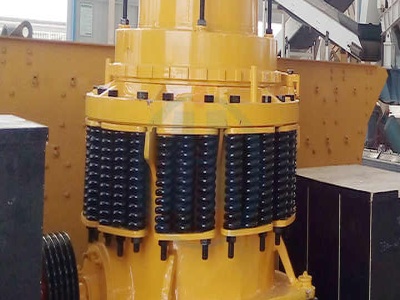

concentrating the ore

Ore concentrate, dressed ore or simply concentrate is the product generally produced by metal ore mines. The raw ore is usually ground finely in various comminution operations and gangue (waste) is removed, thus concentrating the metal component.

gold concentrating solution

CONCENTRATING TABLES Gold mining equipment . Manufacturer of concentrating tables, gold concentrating tables, minerals gravity shaking tables, minerals recovery, metal separation, gold recovery equipment Concentrating Tables are comprised of wooden decks, Our Sales Department will help find the best solution for your mining project.

extraction of metals introduction chemguide

Concentrating the ore. This simply means getting rid of as much of the unwanted rocky material as possible before the ore is converted into the metal. In some cases this is done chemically. For example, pure aluminium oxide is obtained from bauxite by a process involving a reaction with sodium hydroxide solution.

11 Estimation of Iron in Haematite ore solution YouTube

Jul 05, 2017· Now including HGTV, Food Network, TLC, Investigation Discovery, and much more.

what are the steps for concentrating and smelting ...

Dec 11, 2012· Posts Related to what are the steps for concentrating and smelting electrolysis process in zinc smelting process Zinc smelting Wikipedia, the free encyclopedia Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc.

Cyanide Leaching Of Gold

Much thought and design goes into the making of a heap leach, to derive the best, most economical solution for recovering the gold from the ore. Once the gold has been dissolved in the cyanide, and the ore body has been reasonably depleted of its gold, there are two main processes for recovering the gold from the pregnant cyanide solution.

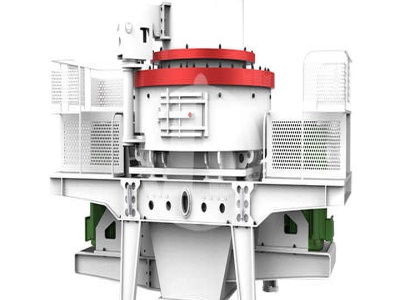

Mineral Beneficiation Processing Cases | Ore Concentrating ...

JXSC, 40 years of troubleshooter in the mining machine and processing industry, shares gold, silver, iron, tin, zinc, copper, diamond, silica, manganese, chrome, titanium and so on Mineral Beneficiation Processing Cases including processing flowsheet, equipment configuration for your reference.

ore concentrating gold

gold concentration in gold ore Solution for ore mining. concentration of gold in ore. Gold extraction Wikipedia, the free encyclopedia Gold extraction or recovery from its ores may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical .

Molarity Dilution Problems Solution Stoichiometry Grams ...

Aug 27, 2016· How to increase and decrease the concentration of a solution by adding water or removing water through dilution or evaporation. 6. Molarity and Dilution Problems M1V1=M2V2 7. Solution ...

Chromite: The only mineral ore of chromium metal

Chromite is important because it is the only economic ore of chromium, an essential element for a wide variety of metal, chemical, and manufactured products. Many other minerals contain chromium, but none of them are found in deposits that can be economically mined to produce chromium.

5 Easy Ways to Calculate the Concentration of a Solution

Jul 10, 2019· In chemistry, a solution's concentration is how much of a dissolvable substance, known as a solute, is mixed with another substance, called the solvent. The standard formula is C = m/V, where C is the concentration, m is the mass of the solute dissolved, and V is the total volume of the solution.

Innovative device offers solution to waterless mineral ...

In addition to low capital and operating costs, a dry gravity concentration process has a number of inherent advantages, such as: WATER – Only requires 70 to 90 kg of water per ton of ore for dust suppression. Wet processes generally require two to three tons of water per ton of ore. AIR is a compressible fluid that can replace water.

beneficiation of chromite ore at concentrate plant

Chrome ore concentrate machine used for beneficiation plant Chrome ore concentrate machine is used in chrome ore beneficiation process. SBM offer machines for chrome ore beneficiation plant . Orissa Mining Corporation Chrome Ore Beneficiation Plant Orissa Mining Corporation Chrome Ore Beneficiation Plant ... was responsible for setting up complete plant ; right from ore entry to final .

Concentration of Ore Solution

Mineral Processing EPC. services of sample test, mine design, equipment manufacture, etc. for clients, and solves the common problems in plant construction such as budget overrun,schedule delays...

Determination of iron (II) by permanganate titration

Bring iron solution (acidified with hydrochloric acid to pH around ) almost to boil. Add drop wise SnCl 2 solution to agitated iron solution till the yellow color disappears and then one drop of excess. Cool the solution. Add fast 10 mL of mercury (II) chloride solution. If the precipitate is gray, don't titrate sample.

Rotainer Containers | Container Solutions | Pit To Ship ...

ISG has a blue chip customer base in both grain and mining and our engineering team has designed containers for cartage of wheat, copper concentrate, Coal, mineral sands, nickel iron ore. Our rotainer container designs are all FEA tested and have gone through a rigorous testing programme.

Uranium Radiation Properties

May 02, 2016· During processing of the solution, large amounts of the radon contained escape into the atmosphere, while the other decay products are transferred to the waste solutions. Those solutions usually are dumped in deep aquifers through disposal wells, or evaporated in ponds, resulting in a concentrated waste slurry.

Low grade ores – Smelt, leach or concentrate? ScienceDirect

leaching (heap or pressure) of copper or nickel from crushed and/or ground ore or concentrate to produce an impure copper or nickelbearing aqueous solution; transfer of copper or nickel from this impure solution to pure, highcopper or nickel electrolyte using solvent extraction;

Latest Posts

- تدفق عملية التصنيع الرسم البياني للمكتب

- تستخدم فقط كسارة مخروطية في السعودية

- قائمة أسعار كسارة الفك السيليكا الأساسية في مصر

- المعدات في كسارة الكلية

- سعر شراء كسارة متنقلة

- سعر تجهيز خام الحديد الولايات المتحدة الأمريكية

- مخروط كسارات للبيع في مصر

- صخرة كبيرة سحق محطات

- شركة تعزيز التعدين في المغرب

- آلة طحن مطحنة الأسمنت

- كسارة آلة مصنع

- الكسارات في محطات توليد الطاقة

- نظام إعادة تدوير الكسارة الصدمية

- الكسارة المتنقلة sbm مصر

- كسارة فكية PE 150x250

- vibrating knotter grinding

- insmart systems manufacturers

- sand ring hammer crusher

- small crushers for artisan gold mining senegal

- hammer mill spare parts design pdf

- portable vibrating coal screen

- sugarcane two roller millma

- tangan mesin penggiling untuk casting

- rock grinders saws

- used limestone jaw jaw crusher mini sale price in algeria

- conveyor idler manufacturing facilities china

- hope agri lava rock quarry

- muelles vibratorios tamiz

- equipments career opportunity

- how to set up a rock crushing quarry