turning and grinding machines

What is the difference between grinding and milling? Quora

Nov 25, 2016· Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials. The precision and surface finish obtained through grinding can be up to ten times better than with either turning or milling.

Toyoda | Machines

Toyoda's complete line of machines range from vertical and horizontal machining centers to grinding machines, bridge and gantry machines to turning centers. Developed with the operator in mind, our machines utilize Fanuc and Toyoda controls for ease of use and optimal efficiency.

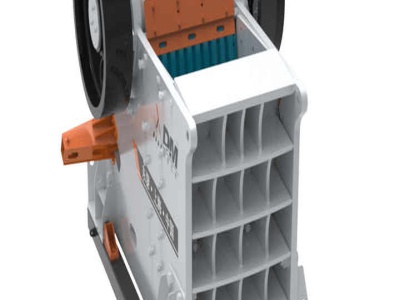

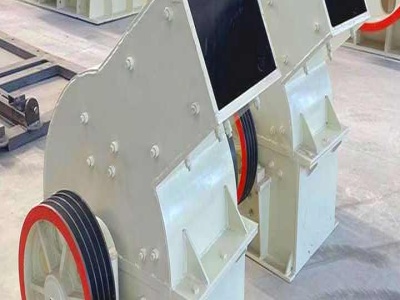

Grinding Machine Types and Uses of a Grinding Machine

Oct 19, 2012· The grinding machine is a type of tool that is utilized for grinding work pieces. It basically use an abrasive wheel as the cutting tool. The rough surface of the abrasive wheel shreds off small portions of the work piece as required. It is also known as a grinder.

Machining vs. Grinding

Machining vs. Grinding Machining is the material removal process that shears/damages the material. D Workpiece Chip Tool+ Chip D Workpiece Abrasive grain+ Cutting with a positive D Abrasive grinding with a negative D

INDEX TRAUB CNC turning machines, automatic lathes ...

The INDEX Group. With its INDEX and TRAUB brands, the INDEX Group is today one of the world's leading manufacturers of CNC turning machines, turnmill centers and production turning machines.

Grinding vs. machining Aerospace Manufacturing and Design

Mar 06, 2017· Replacing a traditional process with grinding depends more on how the part and wheel contact each other than on geometry. Similar to the slotting case, another example uses wheel technology, replacing the turning operation with grinding. Newer nickel alloys used in aerospace can be even more difficult to machine than legacy materials such as IN718.

Grinding Machine Turning

combination hard turning + grinding emag. The process combination hard turning / grinding is used, to great effect, to reduce cycle times. Where the complete hard finishing process (hard turning and grinding) is carried out on a single machine, throughput, .

Ultraprecision Machining Systems; an Enabling Technology ...

diamond turn, and also grind, and this is often accomplished by expanding a lathe platform to one of a grinding platform. This type of machine is however often compromised by inadequate guarding, coolant containment, or stiffness. It is therefore critical that the grinding requirements are considered at .

South Side Machining and Grinding

Located in south suburbs, we offer a small CNC and Grinding Machine shop with large capabilties and faster lead times compared to machine shops in the city that charge more and turn away small jobs.

Grinding Noise When Turning Your Car? CAR FROM JAPAN

May 22, 2018· Solutions for Grinding Noise When Turning 1. The method of preventing noise at the source. The method of preventing noise at the source is the first solution for grinding noise when turning, it consists of isolating it before entering the cabin and reducing the frequency of oscillation. Sound insulation at the source is said to be the most effective method.

Used Turning tool grinding machines for sale Machineseeker

grinding wheel diameter 150 mm Beolmfaoap no. of working stations 2 Stück turning speeds 2800 U/min voltage 400 V total power requirement 0,37 kW weight of the machine ca. 100 kg dimensions of the machine ca. 1,05 x 0,60 x 1,40 m more

MultiAxis CNC Machining, Turning, Grinding, Swiss ...

CNC Turning, Milling and Grinding are at the core of our complex precision machining services, and they have allowed us to serve multiple industries with complete efficiency. Because of our investment in the latest in CNC and Swiss style machine centers, as well as our dedication to mastering their capabilities, our 7 axis grinding equipment is able to produce custom form drills, taps, and reamers to your exact .

EMAG Machine Tools: Turning Lathes and Grinding Machines

From CNC turning machine to hightech production system Comprehensive engineering knowhow forms the basis for production solutions offering the very highest performance. They include manually fed CNC machine tools, CNC turning machines, turnmill centers, CNC grinding machines .

Cincinnati Milling Grinding Machines Serial Numbers Index

May 10, 2016· Cincinnati Milling Grinding Machines Serial Numbers Index The following information on Cincinnati Milacron milling and grinding machines serial numbers is from the second edition of Cincinnati's serial number index from 1953 that was not released into circulation.

Grinding (abrasive cutting) Wikipedia

Creepfeed grinding. CFG has the disadvantage of a wheel that is constantly degrading, requires high spindle power (51 hp or 38 kW), and is limited in the length of part it can machine. To address the problem of wheel sharpness, continuousdress creepfeed .

Used brake turning and grinding machine

Search for used brake turning and grinding machine. Find Centauro and Matra for sale on Machinio.

What is the difference between grinding and milling? Quora

Nov 25, 2016· Turning is usually defined for cylindrical work pieces. This is used to reduce the diameter of a work piece. Milling is more often used when referring to deagglomeration of particles and dispersing them in a liquid medium. Grinding is more often used to reference the process of taking a particle and shearing it down to actually reduce the size.

High Precision Machines | DANOBAT

As a global leader in the market for grinding machines, we innovate and deliver turnkey lines solutions as well as standalone machines for hightech industries and customers demanding the highest technological requirements. Our grinding machines can be customised to suit our customer specific requirements whatever their industry is.

PSeries | Pickup CNC lathe and grinding machine

Fitted with an inner and outer grinding spindle and a VDI 40 turret, the P30 DSS is used for hard machining gear wheels of up to 200mm. The ability to slide the motor spindle along the entire xaxis means that hobbed, geartype workpieces can be subjected to full machining without reclamping.

Latest Posts

- آلة طحن الصعب التعميم الكروم

- الخطوات في إعداد تخطيط مصنع للاسمنت

- مزود الدولوميت المحمول تأثير محطم مصر

- كسارات مستعملة في ألمانيا

- مصانع أسمنت صغيرة

- شركات تعدين الفحم

- قدرة كسارة حجر من 30 طنا في الساعة

- كسارات الحجر اشوكا

- آلة طحن محلية للملح في السعودية

- آلات طحن التوابل الأوتوماتيكية مع التعبئة

- محطم للبيع مطحنة

- سعر كسارة الصخور المستخدمة

- مزاد يستخدم مطحنة التعدين خام التعدين

- نقل مناجم الفحم

- كسارة الفحم إلى 8 مم

- mining equipment placemining equipment placer

- subsidy for dal mill in maharashtra 2013

- download crusher coal price

- miing companies in china

- course grinding training

- which machineris used for gold

- n materiales videos

- used full whiskey barrels for sale in nj

- bayer process idc online

- impeller with foam breaker traders

- feeder breakers for underground mining

- apron feeder in cement plant

- garnet crusher hammerhead

- concrete batch plant quote form

- huddy