how to improve cement grinding process

How Cement Is Made

The heated air from the coolers is returned to the kilns, a process that saves fuel and increases burning efficiency. After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains.

Cement Manufacturing Process: What is Cement made of.

Methods of Manufacturing Process of Cement. 1. Dry Process of Manufacture of Cement. (i) Treatment of Raw Materials: (ii) Burning or Calcination of the Dry mix: (iii) Grinding of Clinker: (iv) Packing and Storage of Cement: 2. Wet Process of Manufacturing of Cement.

clinker grinding unit project report,clinker grinding machine

Shanghai SBM is a professional R D and production to create a crusher, sand making machine and milling machine manufacturers, which was a lot of theoretical research on cement vertical mill R D building, study the influence of vertical mill structure parameters on the grinding body and impact energy of abrasive relationship amplification coefficient and vertical, get increasing revolution speed .

how to improve the lubrication system in cement industries ...

> Ore Process > how to improve the lubrication system in cement industries; Print. how to improve the lubrication system in cement industries. Posted at:December 28, 2012[ 3368 Ratings] ... lubrication system cement industry applications – Grinding Mill ...

Supply Chain Management in the Cement Industry MIT CTL

to clarify the evolution of supply chain management in the cement industry, to propose the right supply ... improve cement manufacturing processes. As a ... Cement in Bulk Concrete Cement Bulk Storage Clinker Clinker Production Clinker Grinding Cement Bags Storage Other Storage. Push Pull. manufacturing capabilities, so SCM may be seen as the ...

Cement | Industrial Efficiency Technology Measures

Cement. Proven technical options with potential to enable considerable reductions in energy use and CO 2 emissions can be categorized into: use of energy efficient technologies; use of alternative raw materials and fuels, and reducing the clinker content of cement via increased use of other blends.

how grinding process in cement plant

Simulation of Cement Grinding Process for Optimal Control of SO ... The control of cement grinding/mixing process in an industrial mill regarding SO3 content has ... the grinding process in cement mill No 6 (CM6) of Halyps plant. Get Price

Additives for Grinding Process

Improve the production rate of the cement grinding system; Increase the early and ultimate strength of the cement; Characteristics and Advantages. SikaGrind®874 MY provides the following advantages in the cement production: Enhanced grinding properties of the cement mill due to less accumulation of material on grinding balls and millliners

how to improve cement mill output

how to improve cement mill output how you can improve cement mill output . Cement mill Wikipedia. A 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage [1] ) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement .

process in cement grinding

Specifically, grinding aids prevent cement particles from reagglomeration, or readhering, during and after the grinding process. Grinding aids make it possible to streamline the cementmaking process by increasing process efficiency and material fluidity.

European Cement Research European Cement Research .

The European Cement Research Academy (ECRA) has decided to broaden its research activities and to set a new focus on "Future Grinding Technologies". In June 2014 ECRA's Technical Advisory Board set a new respective research project in order to improve grinding

mill vertical how to grinding

Improvement of cement performances through the use of grinding ... use of grinding aids can improve both process parameters and cement quality. ... Vertical cement mills are able to reach production values which are...

CEMENT GRINDING | Hilger

Optimized plant performance and perfect process control are indispensable. Cement mills are the biggest consumers of electrical energy. Good grinding organization and intense monitoring can keep grinding cost under control.

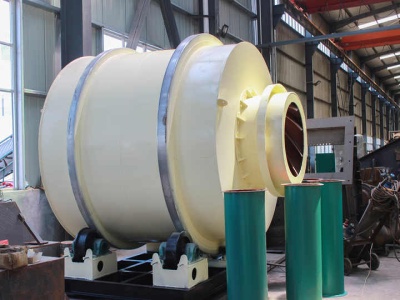

How to Improve Fineness of Cement Ball Mill Product

Ball mill has been applied more and more in various industries, especially the cement industry. Great Wall Machinery has been developing cement ball mill professionally, with simple structure, convenient installation, high efficiency and energysaving features.

Comprehensive understanding of grinding aids Sika

standinG of GRindinG aids. siKa adds value to youR Cement ... improve grinding efficiency significantly (Table 2). ... energy consumed during the grinding process of cement is converted into heat, but a small fraction (≤ %) is retained in the cement as surface

What Is the Cement Manufacturing Process? (with pictures)

Jul 03, 2019· Grinding is the next step in the cement manufacturing process, and it can occur in either wet or dry forms. Wet grinding involves combining all of the materials in a mill with water and grinding it into slurry. In contrast, dry grinding processes combine and grind the materials without water, creating a substance known as kiln feed.

Latest Posts

- صنع السودان كسارات

- المملكة العربية السعودية البائعين كسارة الحجر من جهة ثانية

- كسارة المطرقة للبيع في الجزائر

- آلة الفحم محطم

- أفضل كسارة محمولة للذهب

- تصنيع الحديد الشركة المصنعة محطة

- حساب حصان ناقل برغي في النظام المتري

- الفحم والمنغنيز محطم في جورجيا

- اسم وعناوين كسارات الحجارة في بنغالور

- بأسعار العامة للكسارة الحجر في مصر

- الشركات السعودية حجر المطحنة

- حساب الحمل المتداول لمطحنة الكرة الطاحونة

- تستخدم الموردين كسارة الفحم مخروط

- مصنع كسارة أولية الجرانيت

- تكليف مصنع مطاحن الأعلاف في مصر

- quartz size 4 8 mesh

- perusahaan peralatan pertambangan emas di rusia

- coal crusher 250 ton per in india

- ultrafine grinding mill technology

- grinding plant for petcoke

- crushing sale 40b universal pulverizer

- used ball mill machine in oxl

- outsole grinder machine

- buckets strickland mfg ltd

- apa pungsi chain conveyor

- new stone crusher projects

- truck mounted cranes in texastruck mounted cranes singapore

- small medium spice grinding machine

- britador

- iron ore agglomeration plant