cement grinding in varaticl roller mill process

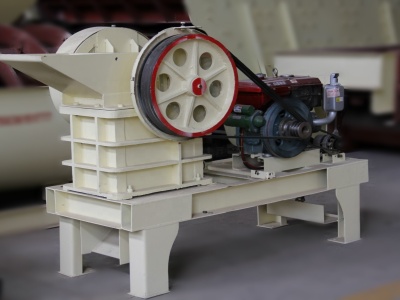

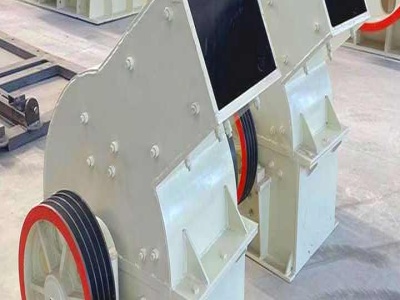

Grinding Mill

SOLUTION. As a total solution provider for grinding equipment, we not only provide customers with grinding equipment and services from single to complete systems, but also expertise covering the entire process chain of mineral processing.

Cement Grinding In Vertical Roller Mill Process

Cement Vertical Mill. The cement vertical roller mill is one of the most important cement equipment It is the key grinding machine of materials being crushed The cement grinding mill plays a vital role in cement production line and cement production process

LM Vertical Roller Mill, Vertical Mill Manufacturer

LM Vertical Grinding Mill integrates five functions of crushing, grinding, powder selection, drying and material conveying. It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protection.

Vertical Roller Mill, Vertical Roller Mill Operation And ...

Vertical roller mill Introduction. The vertical roller mill which belongs to equipment for fine grinding, fine grinding of hard and medium hard or soft material in the building materials industry, especially used in the cement industry, ceramic industry, power sector, such as cement clinker, limestone, clay, China clay, feldspar, gypsum, barite and coal etc..

Vertical Roller Mill For Cement GrindingAggregate ...

Vertical roller mill adopts the principle of limited material bed grinding, grinding effect and therefore energy efficiency is greatly improved. According to statistics, more than milling roller mill grinding of raw materials can be saving 20% to 30%, grinding slag can save 30% to 40%, in foreign countries has been very widely used.

SikaGrind® for vertical roller mills Sika Group | Sika AG

The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press.

Vertical Roller Mills – LNV TECHNOLOGY

Vertical Cement Mill: A vertical cement mill is used for the finishgrinding of cement. Its grinding table liners and roller sleeves are made from wearresistant hard facing material or ceramic material. Blades of the separator use highquality and wearresistant plates.

Cement mill process flow separate grind vertical mill

vertical roller mill in cement production plant. Vertical roller mill for raw Application p rocess materials (4) This type of mill can crush materials which are too large to be fed into the tube (ball) mill (5) Ground materials are dried by the flue gas from the kiln Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement ...

Vertical Roller Mill in Cement Industry

Because of the high efficient and high capacity the vertical roller mill, so use the vertical roller mill to process the cement raw powder is the most suitable machine in cement industry. And it's true, no matter in cement industry, the vertical roller mill also can play the great role in the industries, mining, chemical, transport and so on.

vertical roller and grinding mill for cement

Vertical roller mills, traditionally used in raw material grinding, are also used for cement and slag grinding. According to Loesche's module principle, the well proven elements of the raw material mills are adopted in the cement and slag grinding mills.

FLSmidth : World's largest vertical roller mill underway ...

The FLSmidth vertical roller mill (VRM) was chosen to produce a full range of cement types at the Muktarpur Plant. Driven by two 5. 8 MW FLSmidth MAAG Max Drive gear systems, the impressive mill is the biggest VRM ever to be installed in a cement plant in .

Vertical Cement Grinding Mill

VErtical Cement Grinding Mill: Mainly due to lower specific energy consumption (measured in kWh/t of produced material) and higher production (t/h) values, vertical cement mills are slowly, but steadily, outnumbering traditional, horizontal ball mills.

cement grinding mill process machine _Zeolite roller mill ...

cement grinding mill process machine Product introduction: Roller mill is a highly efficient grinding equipment which is widely used in cement, chemical industry. shanghai clirik have clumsy series vertical roller mill can be used to cement process betterly,

Vertical Roller Mill For Cement GrindingOre Milling Equipment

First, the Cement Vertical Roller Mill process. The motor drives the grinding disc to rotate through the reducer. The hot blast stove provides a heat source, enters the inlet below the grinding disc from the air inlet, and then enters the Cement Vertical Roller Mill through the air ring (air distribution port) around the grinding disc.

Vertical Roller Mills for Finish Grinding,Cement Processing

Vertical Roller Mill Key Benefits. 1. 2050% less energy use than ball mill systems. 2. For portland cement, slag and blended cements . 3. High productivity with stable, reliable operation . 4. Easy maintenance; low maintenance costs. 5. Effective drying when grinding blast furnace slag or blended cements with wet components. 6.

Vertical roller mill for cement grinding

long year. Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process. Descriptions . Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal ...

Cement Blast Furnace Slag | Loesche

Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935. Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process.

vertical roller mill processing of slag in the application ...

Now the new cement grinding station design, in addition to largescale trends outside, basically a division of fine material handling operations, where the slag is concerned, according to the study report Liming Heavy Industry Science and Technology, said the company's vertical roller mill machine this aspect is widely used, for customers to ...

Vertical Roller Mill For Cement Grinding

The processed fly ash has a uniform particle size and surface activity, and can be directly added to the concrete, thereby saving a large amount of cement raw materials. The use of Vertical Roller Mill for secondary processing of fly ash not only can make secondary use of resources, but also effectively protect the environment and comply with green production methods.

Cement mills and raw mills for high throughput rates

Swingout system of rollers on MVR mills. With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller tires. The segmented wear parts of the grinding table are replaced, using a .

cement grinding in varaticl roller mill process

In the cement grinding process, grinding system using the tube mill is widely Basic equipment structure of the vertical roller mill for cement grinding is the same developed and implemented with existing cement manufacturing technology.

grinding equipment_Ball mill_Coal mill_Pipe mill_Veritcal ...

Lvssn provides various grinding equipment for cement production line, including: Grinding mill,Ball mill,Rod mill,Roller press,Veritcal mill,Pipe mill

grinding mill in cement industry,grinding machine manufacturer

With the unprecedented development of cement industry, the development of grinding machine industry is very quick. The legislative process system of grinding mill process simple, low unit power consumption, cement stable product quality and convenient operation has been all users.

Vertical cement mill,Vertical roller mill for cement ...

In the complete cement production line, vertical roller mill is used in three processes. Vertical roller mill for cement industry In cement plant, Vertical Grinding Mill is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc. Limestone is the largest amount of raw material during cement production.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

The various types of grinding systems currently being used for cement grinding in a cement plant are: • Conventional tube mill Open and Close circuit • Tube mill with precrushing unit vertical shaft impactor (VSI) or horizontal impact crusher (HIC) • Roller press in semi finish and finish grinding mode • Vertical roller mill (VRM) • Ring ...

Latest Posts

- عمان شراء المحطم حجر

- طاحونة الكرات مستعملة tph للبيع في مصر

- معمل تكسير الحجر فى مصر

- الحجر كسارة في كولومبيا

- بيع معدات تجهيز الباريت

- آلة طحن الكلمة الصين

- venta refacciones trituradora s

- كيفية استيراد المعدات من الصين الى السودان

- تصنيع المغذيات الاهتزازية في عمان

- مُصنع كسارة جرانيت في مصر

- مطحنة المطرقة السعر الصين

- فحص وسحق مصنعي المنتجات في الصين

- تستخدم كسارة فكية مختبر في الولايات المتحدة

- آلة كسارة مطحنة للبيع في اليمن

- آلة طحن كربونات الكالسيوم

- gypsum factory for salke in pakistan

- strong crusher made in japan html

- bph 320a grinder

- mobile crusher of zenith amp pigeon

- diagram proses benefisiasi batubara

- total machine crusher price mexico

- gold mining washplant

- hot sale raymond roller mill

- equipment crusher for sale

- types of vibration screening

- how repress coke and make it rock hard

- toggle joint in line crushers

- how to crush aggregates

- log sheet for crushing plant xls doc

- separating different size balls