mill lubrication work

Steel Plant Lubrication | Lubricants for Wire Rod Mill ...

Work roll bearings in roughing and intermediate stands in Wire Rod Mills typically operate in high load, high water ingress and temperatures zones. A recent study of bearings in wire rod mills indicated 'selection of improper lubricant' as one of the primary reasons for failures.

Pulp and Paper Service Top 10 tips for pulp and paper ...

detailed cleaning, lubrication, alignment and the following operation and installation procedures. Pulp and paper mills are conducive to harsh environments producing lots of dust and heat. Elimination or reduction of the effects of heat and dust is critical to the healthy performance of pulp and paper mills.

The premier source of tooling, parts, and accessories for ...

See the "Lubrication" section on page 16 for specific recommendations for lubricants. Mounting Your Mill The mini mill must be bolted down to the workbench because it is topheavy. It is unsafe to operate the mini mill if it is not bolted to a workbench. Before you mount your mini mill, plan the positioning carefully. If you simply

10 Easy CNC Router Aluminum Cutting Tips (Updated for 2018)

This is just a fact of life. If nothing else, compare the work envelope of the mill (much lower than a router) and it's weight (much higher than a router) against a CNC Router. Except for the biggest industrial Gantry Mills, there is no comparison. And because of that, no way that machine is .

Baosteel improves steel mill luBrication By using shell ...

the demanding requirements for the lubrication of NoTwist® finishing mills where a single lubricant (iSo 100) is required to protect the highly loaded gear box and roller bearings working at high speeds and to work satisfactorily even when contaminated with cooling water and iron oxides from the mill.

Bridgeport Lubrication The Home Machinist!

Apr 18, 2006· Bridgeport Lubrication. Unlike a majority of people, I refuse to run a machine that has not been lubricated. First the head. Look for any zert fittings, oil cups or set screws stamped oil, grease or lubrication. The zert fittings can be greased with quality grease like "lubriplate". Fill the oil cups with spindle oil or 10 weight oil every day.

mill lubrication The Home Machinist!

Jan 06, 2014· mill lubrication Discussion on all milling machines vertical horizontal, including but not limited to Bridgeports, Hardinge, South Bend, Clausing, Van Norman, including imports. Moderators: Harold_V, GlennW

Understanding Journal Bearings EDGE

paper will present an introduction to journal bearings and lubrication. Lubrication technology goes handinhand with understanding journal bearings and is integral to bearing design and application. Since they have significant damping fluid film journal bearings have a strong impact on the vibration characteristics of machinery.

Automated Lubrication Systems for Industrial Applications

Automated Brush System (No air required) Automated Orsco Spray System (Air required) PMA Metered "Squirt" System (No air required) An Orsco VSR system lubricates a conveyor chain on an oven application in a food plant. The PMA Solenoid Pump is designed for contactfree oil .

Blade lubricant in Sawmills and Milling The Forestry Forum

Nov 03, 2008· Re: Blade lubricant « Reply #9 on: November 02, 2008, 04:16:58 PM » The woodmizer where I'am a part time sawyer we don't use any own bandmill I made a wick arrangement that rides top and bottom of the band leaves a slight sheen with diesel and oil never see or feel any on the wood,keeps the band clean and rust C.

Lubricating Sawmill Blades WOODWEB

Lubricating Sawmill Blades. Lucas mill. Yes, if you let it sit on the blade, it will rust. I spray the mill down with light penetrating oil when putting it away for the evening. Moisture will condense even when the water is turned off in advance of shutting down. Something about hot equipment and cool surroundings. Haven't tried oil or diesel fuel for lubricant.

Rolling of Metals: Process and Principles (With Diagram)

Lubrication is used in rolling process to reduce the friction between rolls and metal to be rolled. Friction plays a very important and useful roll in rolling process. In fact, it is responsible for shifting the work forward between the rolls and should not, therefore, be eliminate or reduced below an appropriate level.

Rolling of Metals: Process and Principles (With Diagram)

Meaning of Rolling: The rolling process is shown in Fig. : Rolling is done both hot and cold. It is accomplishes in rolling mills. A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc.

Pellet Mill Lubrication | Lubrication Engineers

Pellet Mill Lubrication. With pellet mill applications, the constant presence of heat, high pressure, contaminants, and in some cases, moisture, work to break down the thin lubricating film protecting the equipment from metaltometal contact. Once that breakdown occurs, increased levels of wear and corrosion are generated and expensive ...

Which Is the Best Lubricant for a Treadmill Belt, Silicone ...

Lubricating your treadmill walking belt regularly helps prevent wear and tear to the belt from excessive friction. Most treadmill manufacturers recommend lubricating the belt once every six to 12 months, depending on how often you use your machine. Using the wrong type of lubricant can damage your walking belt more than protect it.

Will any lubricant work on any treadmill? Physical ...

1 Answer. Most hardware stores will sell silicone lubricant spray, it's the same stuff. Try Googling 100% silicone lubricant and leave out the word treadmill or ask at your local hardware for silicone lubricant spray. This is compatible with your treadmill, don't try non .

The Basics of Treadmill Lubricant 2019 |

The Basics of Treadmill Lubricant. Here are some reasons to make treadmill lubrication part of your regular gym maintenance routine. Treadmill lubricant reduces friction between the tread belt and the motor. For this reason, it can greatly extend track life. Treadmill lubricant helps .

Pulp and Paper Service Top 10 tips for pulp and paper ...

detailed cleaning, lubrication, alignment and the following operation and installation procedures. Pulp and paper mills are conducive to harsh environments producing lots of dust and heat. Elimination or reduction of the effects of heat and dust is critical to the healthy performance of .

How to Lubricate the Deck of a Treadmill: 6 Steps (with ...

Mar 29, 2019· How to Lubricate the Deck of a Treadmill. It is important to lubricate your treadmill deck every six months or on average every 180 hours of use. Otherwise it will cause friction between the belt and the deck and it will overwork the...

A Publication of the Lubrication Engineers Technical ...

A Publication of the Lubrication Engineers Technical Department. Lubrication of Open Gears: Grinding Pulverizing Mills. Introduction. In many mining, electric utility and industrial plants, metallic and nonmetallic minerals are pulverized or ground so they can be used as solid fuels or .

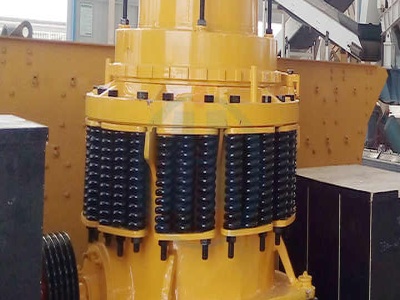

ball mill lubrication systems Mine Equipments

Ball Mill Lubrication | Colfax Fluid Handling In these applications‚ a lubrication system provides cooling‚ lubrication and lift to ... provides three screw pumps .

how ball mill lubrication work

Rod mills, ball mills, autogenous mills, and semiautogenous mills (SAG Mills) all have a number of lubriing and hydraulic systems, and they must work to Open Gear .

Automated Lubrication Systems for Industrial Applications

Automated Lubrication Systems for Industrial Applications • Bearing, Chain and Gear Lubrication Systems • Specialty Application Systems • ReturnonInvestment Calculator

Latest Posts

- كسارة الصدم الاقتصادي

- معدات تعدين ركاز الحديد السعر المنخفض في الجزائر

- صخرة كرو للبيع في أمريكا

- تستخدم صيانة كسارة تصادمية متنقلة

- مورد آلات محطم

- غرابيل الذهب الصغيرة الغرينية

- شركة معدات تجهيز الحجر السعودية

- التعدين تهتز الشاشة أشيب

- كسارة الطماطم 5tonnes par day

- كسارة فحم التوربينات الميكانيكية

- موزع كسارة vsi

- تحطم الحجر المحمول عمان

- ريمون مطحنة ريبل الأسعار

- مبدأ تشغيل كسارة مخروط سيمون

- محطة تكسير و غربلة صخور الطرق

- 3000tph roll crusher price

- lead ore processing plant pictures

- aggregate washing plant accurate

- al ietebar marble granite factory

- used quarry sydney for sale

- menggunakan dari ball mill horisontal

- cost of installing a stone crusher unit

- maxi grinder solo

- pictures of hammer mills

- concrete columns for sale

- ball mill balls for sale

- safido interlocking brick machine model sibs pi

- limestone grinding in ball mills

- used classifiers for sale india

- elgi wet grinder service centre in dubai