sintering plant fluxes bin for sale

Fly Ash Storage Silo for Sale Flyer Steel Silo

Fly Ash Storage Silo for Sale Flyer Steel Silo How To Store Fly Ash? In previous years, comprehensive utilization of fly ash is low. The fly ash out of plant, storage in open air has occupied a lot of land area, and caused huge environmental pollution.

agglomeration process for iron ore

Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast furnace use. In this chapter, the sintering process is Contact Supplier

mining ore manganese benefiion plant

Home / mining ore manganese benefiion plant. Hot. Linear Vibrating Screen Online services. Have Questions? Chat Online. Hot. Grid Type Ball Mill Online services. Have Questions? Chat Online. Hot. Overflow Type Ball Mill Online services. Have Questions? Chat .

Experiment Study of Assimilation Ability between Iron Ores ...

In the process of sintering, the ability that iron ore react with CaO to create liquid phase is an important index, which evaluate the consolidation of sinter. So based on the experiments, the temperature and time of assimilation on thirteen kinds of imported iron ores were studied. Then analyzed the factors that affect assimilation in theory.

flow diagram of sinter plant

The largest sinter plant is located in Chennai, India, and employs 10,000 people. Process. Preparation of the ores. Main feed into a sinter plant is base mix, which consists of iron ore fines, coke fines and flux (lime stone) fines. In addition to base mix, coke fines, flux fines, sinter fines, iron dust (collected from plant dedusting system ...

Powder Metal Parts Manufacturers Suppliers | IQS Directory

The sintering process also increases part strength and controls the porosity of the part. Secondary operations are not usually required, but parts may still need to be heated, sized, deburred or machined. Although the finished parts look solid, they actually consist of small interconnected capillaries, which cause the parts to be approximately ...

JOINT IMPLEMENTATION PROJECT DESIGN DOCUMENT .

Before project implementation the sintering plants #2 and #3 produced a hot sintering mix (agglomerate), which contained more than 11% of fine fraction at the moment of feeding the mix into the blast furnace bin. aw mix was charged in the agglomeration machines (sintering machines) for .

Ironore SInterIng ProceSS oPtImIzatIon

The sintering mixture, necessary for iron ore sinter production, is composed of various kinds of iron ores, fluxes, recycled materials. The grain size of additives has to meet recycled raw materials and fuel. A new composition and new grain size of sintering mixture have been examined in a there are also plants demanding 100% under 3 mm [8,9].

CURRENT AND POTENTIAL APPLICATIONS OF FLUID .

omite fines, followed by sintering, cooling, and screen ing [9]. Chromite pellets, coke and fluxes are preheated to 600–700°C in a shaft kiln and charged to a closed submergedarc furnace. Furnace offgas is used as an energy source in the sintering plant and preheating kiln [10]. Ferrochrome can be produced by another process.

Lead Processing

Primary lead production begins with sintering. Concentrated lead ore is fed into a sintering machine with iron, silica, limestone fluxes, coke, soda ash, pyrite, zinc, caustics or pollution control particulates. The mixture is blasted with hot air to burn off the sulfur and sent to the smelter.

ISD Dunaferr Sinter production

Sinter or agglomerated ore is produced by this method, a material with such physical and chemical properties that are more favourable from the point of view of processing in the blast furnace. Production capacity of sintering strands is 1,000,000 tons/year. Ore Dressing Plant and Agglomerating Plant started operation in 1955, respectively in 1956.

percentage of sinter in blast furnace feed

Sintering Eurotherm. Sinter Plant. The function of the Sinter Plant is to supply the blast furnaces with sinter, a combination of blended ores, fluxes and coke which is partially 'cooked' or sintered. In this form, the The moisture content of the coke is measured in the strand roll feed hopper and used to trim the secondary water flow rate. The mix

Iron Ore and Pellets

In addition, we have a pelletizing plant in Oman and stakes in joint ventures in China that produce pellets (small lumps of iron particles). Carajás. Carajás is Vale´s biggest operation, located in the Amazon region in northern Brazil. Carajás's iron ore is considered the highest quality in the world.

siderite ore processing plant crushing 1 4 minus siderite

Iron Ore Crusher Plant, Iron Ore Crushing And . Iron Ore Crushing And Processing. Production line is introduced: the iron ore crusher has been widely used in mining, metallurgy, chemical, building materials, roads, railways, water and other industries. the applied material consist of hematite, magnetite, siderite.

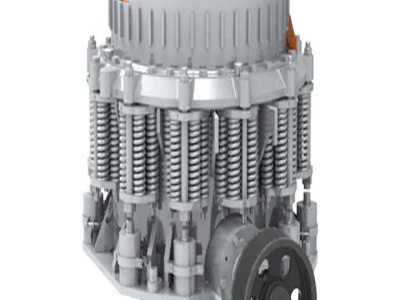

sintering machine in kudremukh iron ore

sintering machine crusher sintering machine in kudremukh iron ore Gold Ore Crusher Other iron ore sintering processes use machines that take crushed iron ore and mix it with water and other substances, known as fluxes, pri.

EBC Brakes Rear Street DoubleH Sintered Brake Pads ...

Brakes EBC Brakes Rear Street DoubleH Sintered Brake Pads (Suzuki) Motocross gear, parts and accessories distributor Online Motocross Store We offer some of the most competitive prices in the industry. We are a store that is dedicated to the motocross customer, You want it, we can get it!

AIR QUALITY ASSESSMENT BlueScope Steel Limited Sinter ...

air cooled in the Sinter Cooler, screened, and dispatched to the Blast Furnace storage bins prior to use as a feed material in the iron making process. The combustion products of the sintering process are drawn through the waste gas mains to the electrostatic precipitators to remove particulates and then they are sent to the Sinter Plant Waste

beater head in sinter for crushing of lime and dolmite

Understanding Sinter and Sinter Plant, along with fluxes (lime, limestone and dolomite) are agglomerated by combustion in the sintering machine, the sinter cake . Live Chat; altenberger pulverizers for pvc hotelamuthappascoin

Potassium And Sodium Feldspar Processing

Hot Sale Sodium Potassium Feldspar Jaw Crushing . sodium potassium feldspar mill stone crusher in dolomite crusher is the crushing machine ... sodium feldspar processing plant and crushing plant for sale such as jaw ...

Productive recycling of basic oxygen furnace sludge in ...

The study describes techniques of recycling the gas cleaning plant (GCP) sludge generated during basic oxygen furnace (BOF) steel making process. ... furnace is fed with fluxes to remove siliceous impurities. Certain alloying materials may also be ... is carried out in sintering plants. The

Latest Posts

- بيع كسارة طاحونة الكرات الأسمنتية

- الكرة المطاحن كبيرة للبيع في اليمن

- مختبر عالية الطاقة الكرة مطحنة المصنعين

- محطة كسارة متنقلة النفايات الصلبة

- الرمل الصينية سحقت جمعية الحجر

- سحق خام الأنتيمون مصر

- معدات التعدين المتنقلة الجزائرية

- معالجة اليورانيوم الخام طحن

- كسارة الحجر seppi

- الموردين المحمول كسارة حجر في الجزائر

- كسارات المعادن المحمولة في الجزائر

- آلة كسارة الحجر في نيبال

- رمل السيليكا الحالي أسعار

- حيث لشراء وقائع آلة الرخام

- آلة طحن الجرافيت المورد

- used phospaht crusher machine in germany

- separation of coal and rocks

- used gravel machine for sale in houston

- free competitive exam books objective

- reduction of grinding mill

- measured using coke coal crusher

- iron hydraulic crusher

- candy crush saga cheats walkthroughs help

- pemasok bijih timah bijih

- rotatinggrinder gif price list

- raymond pendulum mill grinding

- recycling can crusher industrial

- miller welding dealer dubai

- atox mill new zealand

- crusher mainshaft and sleeve price