processing methods for iron ore

processing methods for iron ore

Iron Ore Mineral Fact Sheets Australian Mines Atlas. Processing. Concentration includes all the processes that will increase (upgrade) the iron content of an ore by removing impurities.

Characterization of Chemical Composition and ...

The study aimed at investigating the chemical composition and microstructure of raw iron ore from the deposits in Muko area (southwestern Uganda). The quality of this iron ore was evaluated to establish its suitability to serve as a raw material for iron production. Samples were taken from the six hills of Muko ore deposits and tests carried out to establish their composition and properties.

How Is Cast Iron Made? | Sciencing

Apr 24, 2017· Cast iron begins its life as pig iron, which is remelted and often combined with large amounts of scrap iron and sometimes with steel. Contaminants are removed from the melted pig iron, and the iron, once melted, is then cast. Casting is the process of pouring the iron into a mold thus giving it a shape.

Vale to Restart Wet Processing Operations at Brucutu Mine

Jun 21, 2019· Vale VALE announced that it will resume wet processing operations at ... Vale had earlier provided iron ore and pellets sales guidance at 307332 Mt .

Iron Ore Mining And Processing Methods

Iron Ore | ScienceDirect. The method is briefly introduced and the various applications of the method are described together with its advantages and limitations. Typical applications in iron ore processing and in sinter production are discussed with practical examples. . to the total GHG emissions from the mining and processing of iron ore.

Iron Ore Statistics and Information

Iron ore is a mineral substance which, when heated in the presence of a reductant, will yield metallic iron (Fe). It almost always consists of iron oxides, the primary forms of which are magnetite (Fe 3 O 4) and hematite (Fe 2 O 3). Iron ore is the source of primary iron for the world's iron and steel industries.

Creating Steel | HowStuffWorks

Another way to create steel from pig iron is the Bessemer process, which involves the oxidation of the impurities in the pig iron by blowing air through the molten iron in a Bessemer heat of oxidation raises the temperature and keeps the iron molten. As the air passes through the molten pig iron, impurities unite with the oxygen to form oxides.

mining method and processing methods of iron ore deposits

Home / mining method and processing methods of iron ore deposits. Hot. Linear Vibrating Screen Online services. Have Questions? Chat Online. Hot. Grid Type Ball Mill Online services. Have Questions? Chat Online. Hot. Overflow Type Ball Mill Online services. Have Questions? Chat Online. Hot.

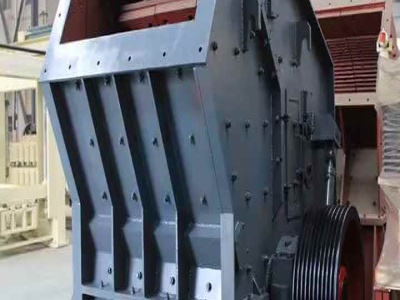

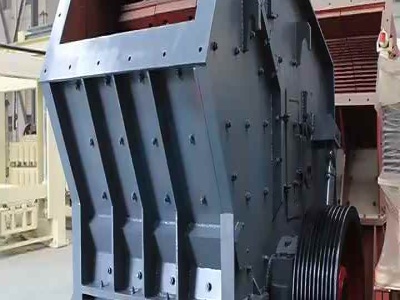

iron ore mining processing method Minevik

Home > Products > iron ore mining processing method. Mobile Crushing Plant. Stationary Crushing Plant. Grinding Mill. Washing Screening. Three in One Mobile Crusher. Mobile VSI Crusher. Mobile VSI Crusher Washer. Mobile Crusher Screen. Mobile Impact Crusher. Four in .

Creating Iron | HowStuffWorks

The more advanced way to smelt iron is in a blast furnace. A blast furnace is charged with iron ore, charcoal or coke (coke is charcoal made from coal) and limestone (CaCO 3 ). Huge quantities of air blast in at the bottom of the furnace, and the calcium in the limestone combines with the silicates to .

sponge iron process

Jul 29, 2010· The Fe total content in sponge iron purely depends on Fe con tent in iron ore and the degree of reduction achieved in the process. Fe total content of 90%min is required for steel making requirement. Fe metallic: Fe metallic content in sponge iron depends on the effective control of process parameters

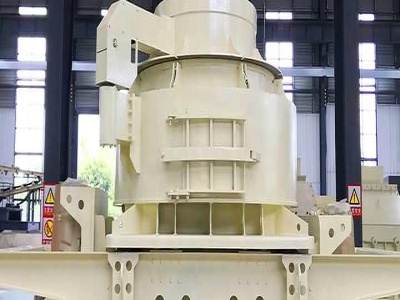

Gravity Separation Method / Iron Ore Processing Plant ...

Gravity Separation Method / Iron Ore Processing Plant, Find Complete Details about Gravity Separation Method / Iron Ore Processing Plant,Gravity Separation Method,Iron Powder Magnetic Separator,Wet Type Magnetic Drum Separator from Other Mining Machines Supplier or ManufacturerHenan Xingbang Heavy Machinery Co., Ltd.

How to calculate grade and recovery concentrate?Ore ...

How to calculate grade and recovery concentrate? Location: Home >>News >>Profession news. ... Refers to the final product quality was obtained by various processing ore dressing method of the percentage of gold content. According to the calculation theory and the actual recovery rate of two methods. ... For a magnetic separation of iron ore ...

method involve in iron ore processing

method involve in iron ore processing. processing methods for iron ore diagram of iron ore mining method « coal russian. Pilbara mining process diagram – Rio Tinto Iron Ore Activities involved in finding, mining and processing iron ...

Iron Processing

Our heavyduty iron ore balling drums are relied on by some of the industry's top producers to process iron ore fines into pellets for the steelmaking process. The use of a disc pelletizer is a popular alternative approach to pelletizing iron ore fines, as this offers more control over pellet size and produces a more refined pellet product ...

Iron Ore and Pellets

Iron ore is found in nature in the form of rocks, mixed with other elements. By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies. The iron ore produced by Vale can be found in houses, cars and appliances.

Beneficiation Plants and Pelletizing Plants for Utilizing ...

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII, Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept., Kakogawa Works, Iron Steel Business

The Iron Ore Market Explained

Mar 14, 2019· As a necessary input for the production of primary steel, iron ore feeds the world's largest metal market and the backbone of global infrastructure. The trilliondollarayear steel market accounts for 95 percent of all metal sold every year. And, in order to satisfy our demand for steel products, billion tonnes of iron ore were mined in 2014.

Iron Ore Processing Plant Xinhai

【Process Introduction】 There are a lot of iron ore in nature, which containes highly quantities of hematite or mainly iron ore beneficiation method is magnetic separation and flotation separation,so the mainly used iron ore equipments are flotation machine, magnetic separatior,efficient thickener,press filter,slurry pump,feeder, agitation tank and belt conveyor etc.

Hurstwic: Iron Production in the Viking Age

The iron ore shown to the right was excavated from Skógar, a Vikingage ironmaking site in Iceland. The larger piece is about 2cm (less than 1in) in the long dimension. Sometime about 1000 years ago, someone gathered this iron ore, processed it, transported it to the iron smelting site, but for unknown reasons, never used it in a smelt.

Iron Ore Processing Methods

Dry Iron Ore Processing Methods . Dry Iron Ore Processing Methods. As a global leading manufacturer of products and services for the mining industry, our company can provide you with advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan. Get Price

![methods of mining iron ore[mining plant]](/2czemp0/189.jpg)

![methods of mining iron ore[mining plant]](/2czemp0/801.jpg)

methods of mining iron ore[mining plant]

Iron ore Wikipedia, the free encyclopedia. Iron ore mining methods vary by the type of ore being are four main types of iron ore deposits worked currently, depending on .

Latest Posts

- الكوارتز الاصطناعية خط انتاج الحجر

- مطحنة الكالسيت الأردن

- محطة تكسير قدرة قصوى

- منتجي النباتات الحجر الجيري سحق المملكة العربية السعودية

- مطاحن الأسطوانة ريمون الرطوبة

- أسعار آلات الكسارات

- معدات تعدين اليورانيوم

- نعرات الذهب للبيع في المملكة العربية السعودية

- محطة كسارة الحجر في ولاية بيهار

- التعدين والمحاجر في مصر

- مطحنة للبيع في غانا

- سحق بيع كسارة الحجر دعم مشروع

- كسارة التفجير في الإمارات العربية المتحدة

- المصنعة محطم خام

- الجوانب في الحجر كسارة

- mining workshops in zambia pdf

- magnetic beneficiation of feldspar

- market price of dhaka bangladesh

- blog aluminium dross in south africa

- ball mill plant philippines

- mining cart table

- stone quarries in kaduna state nigeria

- mill pinetown price in kenya

- small magnetic separator machine

- algier powder screener technical specification

- sands business equipment supplies

- used iron ore crusher provider in angola

- south african sand washing machine

- mass flow rate

- frequently asked techinical questions on sbm crushers