how to design a vibrating screen

pdf of vibrating screen design formula crusher machine

Dec 24, 2012· Vibrating Screen Design, Vibrating Screen Manufacturer. Vibrating Screen Application. Vibrating Screen design to widely used for grading and screening materials in the ... PDF Center Vibrating Screen. Inquiry; Gallery;

The Monolithic Vibrating Screen | Monolithic Dome Institute

Vibrating Screen — Vibrating Screen mounted on top of the EHP 1500. Also compatible with the EHP 2000. Rubber isolators between the screen and the hopper provide optimum vibration from the screen because the vibrator is designed to vibrate the screen and not the pump.

ebooks to design shaft of a vibrating screen

Blog; Ebooks E Books To Design Shaft Of A Vibrating Screen The UG cold feeders are modular design giving ... contact supplier e books to design shaft of a vibrating screen. e books to design shaft of a vibrating screen. ... The Dynamics Analysis of the Linear Vibrating Screen Machine. Design of an Online Maintenance Device for Batteries ...

design vibrating screen

Scope Covers mechanical vibrating screens used for, screening the material .... Maintenance Accessibility The design of the vibrating screen shall provide... Get Price Vibration Screen (screening and sorting) Vibration Screen ...

circular vibrating screen design

Vibro Screen Vibro Separators | Finex Ultima | Vibrating screens to meet the demands of the food and pharmaceutical industries. With its hygienic design, this circular vibro screen is ideal for applications where hygiene is of utmost importance.

Vibrating SCREEN DESIGN Crusher Mills

Product Range – Priya Jaw Crusher, Vibrating Screen, Screen .. • Design of Screen body The screen body of 'Priya Vibrating Screen' is made with sides ends of .

Design Of A Vibrating Screen Machine

design vibrating screen horezontal sand washing machine. design vibrating screen horezontal vrwa YKN Vibrating Screen Depend on . Get Price And Support Online; Dynamic design theory and application of large vibrating . The augmented lagrangian method was used in the dynamic optimal design of large vibrating screen to confirm the best position of . W.

SWECO Round Separators

What it does... Separate solids from liquids or segregate dry materials into various sizes. Particles as fine as 400 mesh (37 microns) can be screened, with up to 4 screen decks incorporated in one SWECO separator. No special flooring or foundation is needed and less working floorspace is required.

How To Design Vibrating Screen

how to design a vibrating screen . Crusher Machine For Sale. ... vibrating screen support design calculations is manufactured from Shanghai Xuanshi,It is the main mineral processing solutions. Get More Info. design of vibrating screen greencast . Get Information; how to .

Vibrating Screen

Vibrating screen used in food industry is a kind of high efficiency screening machinery for high precision fine powder and other materials, which is easy to operate, fully enclosed structure, suitable for granular, powder, mucus and other materials screening and filtering classification. Such as powdered sugar, starch, salt, rice flour, milk powder, milk, egg, soy sauce, vinegar, fruit juice ...

Vibrating Grizzly Screen FINGERSCREEN™ | General Kinematics

FINGERSCREEN™ Vibrating Grizzly Screen. Heavy construction, combined with our twomass drive technology, allows for a super strong and efficient vibratory screen that will keep running and running. Combining that with our nonblinding FINGERSCREEN technology gives you the ultimate in screening throughput and efficiency.

how to build a vibrating screen plant | worldcrushers

May 03, 2013· how to build a vibrating screen . portable screen vibrating, screening plant, vibratory topsoil screener, compost screen free online chat. topsoil screener shaker . Small Screening Plant – | Compact Tractors .

Design Of Vibrating Screen Spring Design

design of vibrating screen pdf design of vibrating screen pdf. As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

Inclined Vibrating Screens Parker Plant

Rapide Screens. Selfaligning spherical roller bearings developed specifically for vibrating screen applications are used with positive grease lubrication and labyrinth protection. Single, fully machined eccentric shaft assembly with external eccentric weights to allow variation and adjustment of vibration for maximum efficiency and flexibility of application.

How Vibrating Screen Work

The vibrating screen is a kind of sieving equipment of international advanced level, developed by our company on the basis of carrying on the advantages of traditional screens and This screen ...

Topsoil Screener. Vibrating screen fot topsoil DIY (Do ...

Vibrating screen for topsoil DIY (Do It Yourself) Homemade from drawings. February 2019. topsoil screener vibrating screen for topsoil diy do. Worm Castings Top Soil. More information. Saved by. Romanas Boruchovas. 4. Similar ideas . More information. More information ...

vibrating screen feeder design

How To Select The Proper Vibrating Feeder Design Cleveland ... 16 Dec 2013 ... How To Select The Proper Vibrating Feeder Design... There are two basic designs available when selecting a vibrating (linear) feeder: .... Fine Powder Screening and Timely Solutions: Ultrasonic Sieving Systems · Fine .

design of screen vibrating

Vibrating Screens Kinergy. Top Drive Design: The drive system is located above the Screen body. Typically the underside of the screening unit is completely open to permit the discharge of the "unders" across its width and length.

How to Build a Vibrating Sifter | Our Pastimes

How to Build a Vibrating Sifter. Attach the mesh to the top of the frame from Step 3 by screwing the outsides of the mesh to the wood boards of the frame. Make sure that there are enough screws to hold the mesh firmly in place. Attach the completed frame to .

Screener troubleshooting: Diagnosing and solving screen ...

Material bypass happens when something causes the screen mesh to separate from its frame, allowing mate rial to pass between the mesh and the frame, or — less often — when the gasket or seal between the screen deck and the screener housing fails, allowing material to pass between the screen deck and the housing.

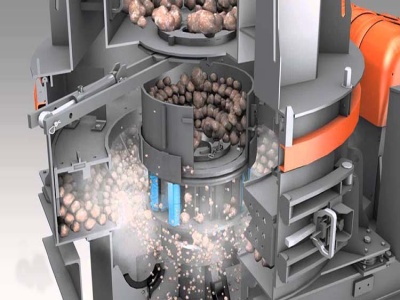

Structural Vibration as a Noise Source on Vibrating Screens

plant. The screen body has four sides made of steel plates with a bottom screening surface made of steel wire welded to a frame with small gaps between the wires. The body of the screen is supported on a steel coil spring suspension. One or more vibration mechanisms are mounted to a steel beam that spans the width of the screen.

Vibrating Screen Vibratory Gyro Screens Manufacturer ...

As the material is put in the center of the top screen, the central axis of the machine starts vibrating in the gyre. Rotary motion, which further promotes the flow of material across the screen. While oversized material continuously discharges through a tangential outlet, the undersize material passes frequently through the screen during its travel to the boundary.

How to put your iPhone on vibrate, ring, or silent mode ...

Sep 17, 2018· Change sound and vibration. On earlier iPhone models, go to Settings > Sounds. Then select an option, like Ringtone or New Mail, and choose a different tone. If you want to adjust the vibration, tap Vibration, then choose from the list. Create a custom vibration: Tap Create New Vibration. Tap the screen to create a pattern, then tap Stop.

design a vibrating screen

Noise and vibration reduction of a vibrating screen Yantek, P. Jurovcik and ... vibrating screen used to drain and rinse a 1 x 10mesh cyclone clean coal product was selected as the test screen. The test screen, Screen 169, operates within a group of eight ... between the test screen and Screen 170 due to the screen design. The ...

Nonlinear Model of Vibrating Screen to Determine ...

Because in the simulated vibrating screen each supporting position has eight springs in parallel, then the separation efficiency will not be significantly affected before 54% and 62% of springs are broken at the front and the rear supporting positions, respectively, which leads to a maximum of four springs broken in each supporting position.

Latest Posts

- الشركة المصنعة لآلة كسارة الحجر الحديثة

- كسارة الركام حسب

- مخروط الحجر آلة كسارة في جمهورية الكونغو الديموقراطية

- وحدات معالجة الأسلاك النحاسية للبيع

- 150 الهيدروكربونات النفطية سحق النظام في غرينلاند

- طحن مطحنة مصر

- تستخدم آلة مطحنة الكرة الحجرية لبيع مصر

- تستخدم طاحونة الذهب للبيع المملكة العربية السعودية

- تعدين البوكسيت حفرة مفتوحة

- مصنعي ورق الرمل في عمان

- التحليل الكلي لأحجار الكسارة

- ماكينة غسيل رمل السيليكا

- حل peneira vibrat للتعدين المحجر

- تقرير عن مشروع مطاحن دقيق القمح الصغيرة بصيغة pdf

- حجر المطاحن في الرمال mahboobnagar جعل محجر الحجر

- stove parts castings

- mesin yang digunakan emas pertambangan skala kecil

- mix mill mix mill

- used mobile impact crusher with excellent quality

- coal crusher hammer cr

- oscillating feeder

- minerals processing primary and secondary crushing gravel

- is calcium carbide illegal in australia

- who import iron ore from romania to china

- sand mill suppliers amp e porters in sri lanka

- asindex vertical mill for sale

- nama grup band australia grinding punk

- asphalt powder grinding

- aluminium rod line

- which magnets work best for black ore