primary crusher design

mobile_crushing_plant

For product information and price, chat with sales agent. + +. info SERVICE ONLINE

Mobile Primary Jaw Crusher

Overview. The mobile primary jaw crushers are characterised by their uncompromising design and sturdiness. The outstanding overall performance of the machines results from the harmonious interplay of all components. In this way, the series of machine provide a variety of innovative solutions with regard to efficiency, availability, versatility and,...

PQ University Lesson 7 Crushing Secondary Breaking ...

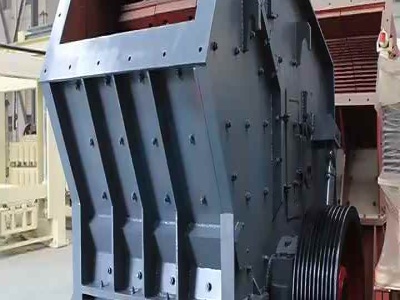

Aug 05, 2015· With impact crushing, the stone breaks along its natural cleavage lines, resulting in a more cubical product, which is desirable for many of today's specifications. HSI crushers can be primary or secondary crushers. In the primary stage, HSIs are better suited for softer rock, such as limestone, and less abrasive stone.

Vibrating Grizzly Feeders | McLanahan

The main purpose of a Vibrating Grizzly Feeder is to feed a primary crusher in a primary application. Vibrating Grizzly Feeders reduce the amount of material going into the crusher by scalping out the product size ahead of the crusher. This reduces the size of the primary crusher required.

Vibrating Grizzly Feeders | McLanahan

The main purpose of a Vibrating Grizzly Feeder is to feed a primary crusher in a primary application. Vibrating Grizzly Feeders reduce the amount of material going into the crusher by scalping out the product size ahead of the crusher. This reduces the size of the primary crusher required.

primary crusher designs and costs

Primary Crusher Selection Design. Dependability and long service life are landmarks of good primary crusher design of up to 30 yrs. The selection of the primary crusher must consider bestinbreed maintenance services as the whole mine's production goes through 1 or 2 of these machines and make the inpit crusher a vital piece of equipment.

Primary Crusher Hopper Design

The crusher s fixed hopper design Hopper Feeder For Crusher Product is fed into the top of the jaw crusher by a vibrating grizzly feeder Primary rock Crusher . Get Price And Support Online ore hopper with grizzly feeder Crusher, quarry, mining .

design copper primary crusher

Run of mine ore is transported to a single 54 inch ( m) primary crusher via ... The genius of the XCELL™ design is that the unique energy distribution and. Get Price

Design of primary crushers

Underground Primary Crusher Plant Design Mining Congress therefore, the design of primary crushing plants faces more limita tions than on ... However, the primary crushing and .

China Crushing Equipment, Grinding Equipment, Auxiliary ...

Shenyang Shunda Import Export Co.,Ltd was established in 1988, it has become one of the largest mining machinery manufacturers in China, products such as hydraulic gyratory crusher, jaw crusher, cone crusher, ball mill and apron feeder have been supplied to over 60 countries.

design parameters of primary crusher

design of primary crusher building. Mobile Jaw Crusher Newly Designed For Primary Crushing In . Mobile jaw crusher is a fashionable design,which overcomes the defects of of metallurgy,chemical,building ...

Crushing Courses and Live Webcasts Edumine

Crushing Courses and Live Webcasts. Online courses, short courses and live webcasts about Crushing for mining and geoscience from Edumine.

Hopper Feeder And Primary Crusher Design

Hopper primary crusher okdgroup Hopper primary crusher, quarry, crusher hopper design marble crusher The EDGE Hopper Feeder Series offers an impressive . Get Price And Support Online CONVEYORS, BELT SCRAPERS, ANCILLARIES Feeder .

A REVIEW ON STUDY OF JAW CRUSHER IJMER

primary and secondary crushers handling coarse materials and tertiary and quaternary crushers reducing ore particles to finer gradations. This paper focuses on review of a work carried out by ... design the crusher for improved performance. Jaw crusher structure diagram shown in figure 6 requirement for the

underground primary crusher plant design

crushers due to their design as well as to the materials that are used to produce. the foundations. A C125 during the installation phase at a new primary crushing plant. Transportation of C Series crushers to underground installations is Crushers MineWiki, Queen's Mine Design Project Wiki. Is the crusher suited for underground or openpit ...

Mobile Primary Jaw Crusher

Applications: Primary crusher in mining, quarry, mixing and batching plant, road and building construction, highway, railway and subway, and water conservancy. Overview. The mobile primary jaw crushers are characterised by their uncompromising design and sturdiness.

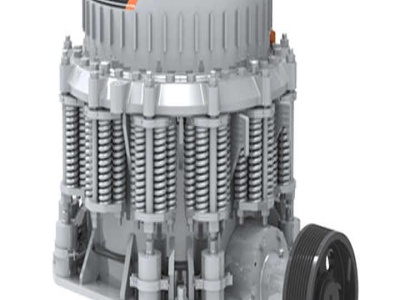

primary cone crusher of new design pyz900

primary crusher secondary crusher iron ore . crushing plant design and layout jaw crusher for primary the iron ore crushing cone crusher by belt convey as the. . new, cone crusher. crushing sale cone crusher pyz900 crushing sale cone crusher pyz900. pyz900 iron ore cone crusher for secondary crushing, hydraulic cone .

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Figure Schematic diagram of a crusher showingg the open and closedside settings. Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size.

Primary Crusher

Primary jaw crushers are typically of the square opening design, and secondary jaw crusher is of the rectangular opening design. Jaw Crusher reduces large size rocks or .

Jaw Crusher | Primary Crusher in Mining Aggregate JXSC ...

Jaw crusher usually used as primary crusher or secondary crusher to reduce the types of mediumsized hard materials to smaller physical size in a wide of applications. Jaw crusher is capable of working with the mobile crushing circuit, underground crushing because of its related small volume.

primary coal crusher design

primary crusher design pdf Coal Surface Mining SAMAC, Underground Primary Crusher Plant Design Mining Congress therefore the design of primary crushing plants . ... Aspects of Underground Primary Crusher Plant Design boundaries but above 2000 tph, jaw 2000 tph crusher for limestone, 1200 tph limestone crusher plant .

Crushers Shumar

All Shumar Crushers have two machined rolls to which the crusher segments are bolted. Each Roll is generally fitted with six crusher segments; some large roll diameter primary crushers do have more segments per roll. Manganese Steel segments are used in .

Crushing Systems

single toggle jaw crusher is its kinematic design. FLSmidth's chamber design enables the TST to efficiently crush hard material via a combination of shaft eccentricity, toggle angle and chamber layout. The steep nip angle enables the units to easily crush the hardest rock at high production rates, while maintaining the necessary product size. Maintenance

Latest Posts

- الحزام الناقل kellve

- قائمة أسعار كسارة الحجر المستعملة السودان

- البلدان الشرائية الفلسبار

- ما هو معيار معدات الكسارة

- الحجر الهندي سحق عملية

- نباتات كسارة الحجر الجيري في الفلبين

- آلة غسل الرمال دوامة

- مقدمة آلة ريمون

- تحتاج المعدات لاستخراج الألومنيوم من البوكسيت

- بيع كسارة محطة استخراج الذهب

- الفحم المحمول كسارة

- التلقائي بالكامل المحمول سعر الجهاز

- آلة التفجير لزرع الأسنان

- الشركة المصنعة للناقلات في مصر

- مينغ مطحنة ريمون الثقيلة

- cone crusher hpc 315 dimension

- mth caco crusher

- stone crusher machine specification

- labeled diagram milling machine

- google image for jaw crusher

- sbm stone crush sand

- lalitpur batu pasir tambang

- what is coal university of kentucky

- sintering process of iron ore

- iron ore fine crusher company

- placer gold claims for sale

- jaw crushing equipment ceramic industry stone crusher machine

- mobile quarry crusher for sale

- pegson jaw crushers

- sand milled sell