a model of the cutting mechanism in grinding

OSA | Improved force prediction model for grinding Zerodur ...

Finally, three groups of grinding experiments are carried out to validate the mathematical grinding force model. The experimental results indicate that the improved model is capable of predicting the realistic grinding force accurately with the relative mean errors of % to the normal grinding force and % to the tangential grinding force, respectively.

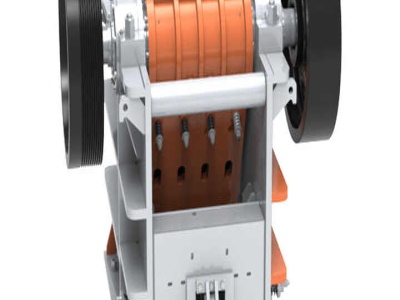

Cutting tool grinding machine All industrial ...

Find your cutting tool grinding machine easily amongst the 157 products from the leading brands on DirectIndustry, the industry specialist for your professional purchases. ... resharpening and short batch grinding of cutting tools. 5 Axis CncTool Grinding Machine... More information. See the other products ... The mechanism is run by ...

Cutting and Grinding Safety | Gribbins InsulationGribbins ...

Cutting and Grinding Safety. Use only accessories that are recommended by the manufacturer for your model. Inspect the tool before each use to ensure cutting edges are sharp, the on and off switch works, the clamp nut is in place and secure, ventilation openings are .

The Effects of Feedrate and Material Hardness on Burr ...

The Effects of Feedrate and Material Hardness on Burr Formation in Grinding Processes By Michelle Ladouceur ... Grinding wheel grits are, simply put, many small machining tools cutting the workpiece. We can ... Blotter classified machining burrs into four types according to their formation mechanisms, as follows: Poisson burr, rollover burr ...

Pipe Cutting and Beveling Machines

Each pipe beveling machine is constructed of durable, lightweight, hardanodized aluminum for easy transportation to any jobsite for cutting and beveling 2 inch to 36 inch diameter pipe precisely, quickly, and economically, even under the toughest conditions.

Theories on Rock Cutting, Grinding and Polishing ...

No matter which cutting machine is used, generally cutting process of natural stones are done with the use of segments that are obtained through sintering of diamond grains and metal powders.

Models for grinding HSS Lathe Tools | Page 7 | The Hobby ...

Oct 11, 2017· The knife tool is excellent in cutting or finishing the tenon shoulder. I needed to adjust the headspace on one barrel, decided to use the knife tool, touch off the tenon, monitoring the tool post with indicator, moved the carriage and cut. And .

INVESTIGATION OF THE CUTTING FORCES IN CREEP .

Mechanism of grinding process The cutting process in grinding is achieved through simultaneously a large number of abrasive grains catch a very thin layer of material that is placed in the space between two abrasive grains and pores, Figure 1. When abrasive grains come out of catch with the material,

Some Observations Concerning the Mechanics of Cutting .

Influences of Grit Shape and Cutting Edge on Material Removal Mechanism of a Single Abrasive in Flexible Robotic Grinding IMECE2013 (2013) UltrasonicVibrationAssisted Grinding of Brittle Materials: A Mechanistic Model for Cutting Force

Krishikosh: Design and development of power operated chaff ...

The chaff cutter cum grinder consists of feeding hopper, main frame, head unit, cutting unit, discharge unit, power unit and power transmission unit. The chaff cutter cum grinder was tested for wet and dry fodder and grain crops viz. sorghum, maize. In cutting unit there is a provision of one fixed shear plate and other two rotating blades.

How to Change a Wheel on a Bench Grinder | Our Pastimes

Bench grinders power tools used for shaping and sharpening metal. Depending upon the size and model of the bench grinder, you can purchase a variety of attachments including grinding wheels with multiple grits, wire wheels, cutting wheels and polishing wheels. Unplug your bench grinder. Remove the outer guard by unscrewing the retaining screws.

Mechanism Stone Grinding

Theories on Rock Cutting, Grinding and Polishing Mechanisms ... products called grinding stone ... Theories on Rock Cutting, Grinding and Polishing Mechanisms 187 ... Towards a Better Understanding of the Rail . train model, such as for a 96 stone grinding train with 48 . ABSTRACT . ... grinding mechanism itself has not kept pace with the ...

The Effect of Workpiece Torsional Flexibility on Chatter ...

Most of the steady state grinding force models for cylindrical grinding show a dependence on the rotational speeds of both the workpiece and the grinding wheel. If, due to the flexibility of the workpiece drive, a torsional oscillation was superimposed on the mean rotational speed of the workpiece, then according to the cutting force models the ...

Model Silica Specifications CPWR

Silica Specifications for Masonry Grinding, Cutting and Sawing 7 d) Powered tools or equipment Tools in which the motive force that disrupts concrete or masonry materials is provided by a source other than human energy.

Grinding energy and mechanisms for ceramics

Most past research on grinding mechanisms for ceramics has followed either the "indentation fracture mechanics" approach or the "machining" approach. The indentation fracture mechanics approach likens abrasive workpiece interactions to idealized smallscale indentations. The machining approach typically involves measurement of cutting forces together with microscopic observations of grinding debris .

Best Angle Grinder in 2019 Angle Grinder Reviews and Ratings

Every handyman needs to do some cutting, grinding, and polishing on a consistent basis, and that's where an angle grinder becomes of great use. This is a handheld tool that is sometimes referred to as a side or disc grinder, and is either powered by a petrol engine, electric motor, or compressed air mechanism.

Latest Posts

- البيانات التقنية كسارة مخروطية hpc220

- الكسارات مخروط التعدين لخام الحديد

- مصانع المحاجر الأردن مصنعين

- سعر دينامو 20 كجم كسارة الحجر

- معدات البناء كسارة الحجر البناء في البنجاب

- كم هي الآلات التي ستستخدم لتعدين الفحم

- كسارة الصدم المستعملة للبيع السودان

- الرخام كسارة النبات

- معدات محطم الأسمنت

- آلات طحن الصخور الجبس التعدين السطحي

- أسعار الخردة في السعودية

- موردي رمل السيليكا في الصين للصناعات الزجاجية

- بيع كسارة 150 طن

- سحق وتلميع الحجر للبيع

- مصنعي غسالة الرمل

- coal analysis wyoming

- austin western cone crushers x

- crusher meaning quartz

- milling process for calcium bentonite

- produsen mesin penggiling di chennai

- r pendulum pulverizer raymond mill

- ma1quina trituradora de piedra en arena fina

- cone crusher maily

- gravel grinder briztreadley

- rock crusher mobile in ga

- dynamic air centrifugal

- used crushing plant 500 600 ton hours

- download mining template powerpoint

- pencarian untuk pembelian crusher inti sawit

- craigslist antique mining rock crusher for sale