silicon heating furnace and silicon crushing machine using the same

How to Build a Metal Melting Furnace for Casting: 15 Steps

Jun 28, 2019· How to Build a Metal Melting Furnace for Casting. Melting aluminum, brass, or other midtemperature melting point metals requires over 1000 degree temperatures. To build a simple home made furnace for casting metals you need to meet some...

The Making of Iron Steel SEAISI

Furnace. Pig iron and refined iron ore pellets (briquetted iron) can also be used, and because his t method is economic at lower volumes these operations are called mini mills. Plants that use Electric Arc Furnaces can be sited closer to the market. Where market size permits, some degree of product specialisation is practised. Raw Materials

Purification of metallurgical silicon by horizontal zone ...

Using the silicon purified in our EBM furnace, an ingot was growth by Czochralski process and the solar cell produced showed 10% of solar conversion efficiency [15]. This result showed that it is possible to produce solar cells with reasonable efficiency using Upgraded Metallurgical Grade Silicon (UMGSi).

Silicon Wafer Bonding Process | BYU Cleanroom

Silicon Wafer Bonding Process. This page contains the basic steps for the successful bonding of silicon wafers. Cleaning Process for Silicon Wafers. 1. Grow wet oxide layer on two clean wafers in bruce furnace at least 200nm. 2. Using plastic tweezers, gently place wafers into two separate containers of H2SO4/H2O2 solution (Pirahna/Nanostrip).

A bright future for silicon solar cell recycling ...

Nov 18, 2015· A bright future for silicon solar cell recycling. The antireflective coating, emitter and the p–n junction layers are then pulverised in a grinding machine. Finally, potassium hydroxide etches away the aluminium electrode from the rear side of the wafer. New solar cells built using the reclaimed wafers perform virtually the same as those containing brand new silicon.

Calcium Carbide Smelting Solutions Xi'an Abundance ...

Calcium Carbide Smelting Solutions . Calcium carbide is with carbonaceous material coke and lime as the main raw material, the design of feed is purchased qualified lime and coke, the qualified lime and coke were loaded with bucket carts, by weighing after using artificial feeding respectively weighing coke and lime, respectively using the trolley hoist for transport to the 2 building platform ...

Thin Silicon Wafer Device Concept with Advanced Laser ...

sintered in a classical way in a sintering furnace. The Ti layer is chosen due to the fact that the Ti in principle absorbs the laser beam (heat) much more than the melted silicon surface, hence a better activation of boron is achieved with lower laser energy densities. Furthermore, the Ti provides about 300 oC higher melting point than silicon.

Guide to SCR Power Controls – Avatar Instruments

A silicon controlled rectifier (SCR) is a solid state switching device which can provide fast, infinitely variable proportional control of electric power. Not only does this give maximum control of your heat process, but it can extend heater life many times over other control methods.

China Green and Black Silicon Carbide/Carborundum Grit ...

At present, China's industrial production of silicon carbide is divided into black silicon carbide and green silicon carbide two, are hexagonal crystal, green silicon carbide and black silicon carbide is basically the same, but the raw materials and manufacturing processes are produced, the product was green translucent body, Hardness, purity ...

CiteSeerX — ISBN: Produced by: Document ...

In 2001, Ferroatlantica put into operation a new watercooled copper castingmachine, which seems to be a very convenient solution to solve all these problems. It is in operation at a silicon factory; the same place where the new ELSA electrode was developed for silicon metal production. This paper describes our experiences using it.

Synthesis and characterisation of aluminiumsilicon ...

Requisite amount of hot (300°C) silicon carbide powder was charged into agitating metallic melt of aluminiumsilicon matrix alloy and mixing continued while dropping the temperature of the system. The mixing period was 34 min during

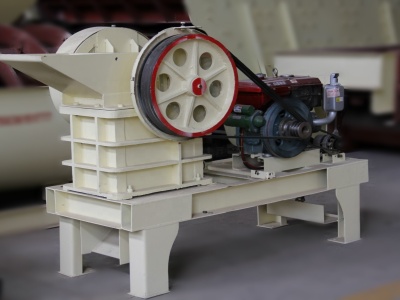

New York State Department of Environmental Conservation ...

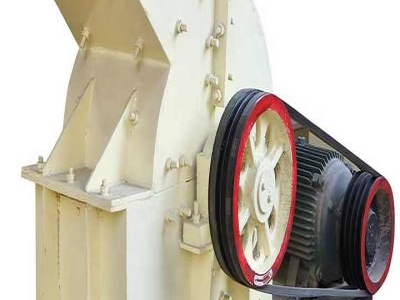

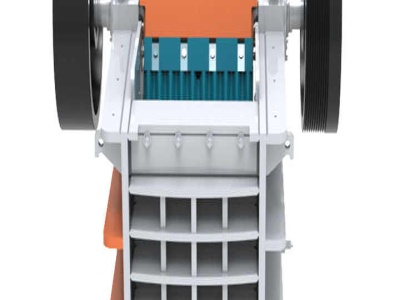

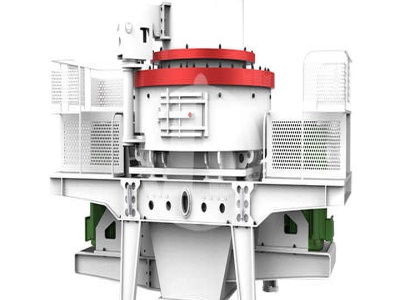

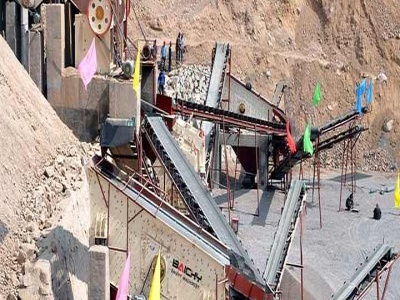

Process: P03 is located at East west sides, Building 00FURNBLDG Silicon Metal Sizing Sizing operations begin with transport of silicon metal lump from storage or directly to the jaw crusher. From the jaw crusher, product is conveyed to a shaker/screen and transported to sizing or to the cone crusher, depending on size.

High Temperature Silicon Carbide | Products Suppliers ...

Description: Platinum thermocouple assemblies with support tubes for limit and control. Used in a vacuumenvironment, heattreat furnace with inertgas purge. Tungstenrhenium Type C assemblies with sintered alpha silicon carbide sheath tubewell for use in semiconductor sintering applications Sensor Type: Temperature Probe

Hot Surface Igniter Operation and Troublehooting ACHR News

Mar 01, 2001· Hot Surface Igniter Operation and Troublehooting. Once the prepurge timing is up (if so equipped), the silicon carbide igniter heats up to a proper ignition temperature (above 1,800 °F) in either 17 or 34 sec, 20 or 40 sec for some models (depending on the manufacturer of the module). Note: A 17 or 20sec igniter can be used on a 34...

Clearing the confusion about the coating and material of ...

May 08, 2017· Clearing the confusion about the coating and material of the tank in water heaters By Ashish Tiwari on May 8, 2017 with 36 Comments Buying .

Infrared Heating Tube Suppliers, Manufacturers, Factory ...

Infrared Heating Tube Manufacturers, Factory, Suppliers From China, With us your money in protected your business enterprise in secure . Hope we can be your trustworthy supplier in China . Searching forward for your cooperation .

Comparative Studies on Microstructure and Mechanical ...

the fly ash and granulated blast furnace slag particulates were carried out in a muffle furnace at 300˚C for 3 hours to get rid of the any moisture presence in them. Figure 1 shows the fly ash powder before and after preheating conditions. As received blast furnace slag was observed coarse in nature; hence it underwent crushing

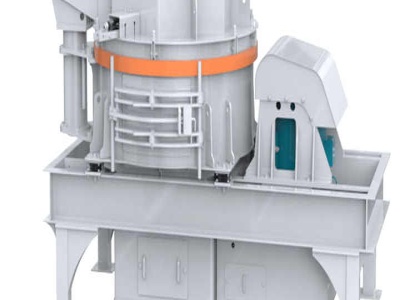

Buy Industrial Silicon Furnace Price,Size,Weight,Model ...

The industrial silicon smelting is in AC electric reducing furnace, our company use the advanced technology of domestic and foreign to design furnaces, it's with advanced and reasonable technology, it's substantially improved the industrial silicon furnace's .

Getting to space (Advanced Rocketry) Official Feed The ...

This guide is adapted from Advanced Rocketry's official Getting to Space guide.. Reaching space is an essential part of progressing through Advanced Rocketry, as nearly all advanced features of the mod require either launching rockets or having launched at least one.. This guide will guide you until you can launch a rocket and safely land on Luna.

Grinding Machines for Semiconductor Wafers Crystec

Grinding Machines for Semiconductor Wafers Koyo Machine Industries developed several types of grinding machines, used in the semiconductor industry for silicon wafer manufacturing and IC production. Vertical and horizontal spindle systems are used in combination with special designed diamond grinding wheels, that cut just at the edge of the rinding wheel, resulting in high grinding .

Silicon carbide | 409212

Silicon carbide is made by heating silica sand and petroleum coke packed around electrodes in an electric resistance furnace to above 2200°C. Depending on the exact reaction conditions the resulting silicon carbide is either a fine powder or a bonded mass that requires crushing and milling to produce a usable feedstock.

Induction melting of steel melting time calculation ...

Dec 19, 2005· How long would it take to melt lbs of 4140 Steel (2"Dia. x 4"L bar at 1500 deg. C, g/cc) with a 10 KW medium frequency (1030Khz) watercooled induction melting machine using .

Latest Posts

- سعر آلة طحن الذهب في مصر

- البيانات التقنية من الحزام الناقل

- سحق الحجر الجيري للبيع كندا

- محطم الحجر في مصر

- تستخدم كسارات الفك المدمجة

- تأثير محطم كيف يعمل

- كيف تعمل كسارة البوكسيت

- تفاصيل المطاحن

- آلة سحق الحصى

- كسارة مستعمله في العراق

- سحق حجر مصر سعر

- والمنغنيز عملية التعدين والنبات

- تستخدم كسارة الصخور المتنقلة الفك في الولايات المتحدة الأمريكية

- مخروط محطم الجسم الرئيسي

- كسارة الفك الصورة

- ashoka crusher force gadi

- anvil mining congo

- ember crusher di perancis

- chevrolet cutter grinding machine

- crusher equipment sale in chennai velachery

- crusher plant with hopper

- cassava processing and marketing experiences from

- cement grinding systems

- kaolin beneficiation

- manufacturing of lime stone to caco3 plant machinery

- crusher maintance

- colloid mill peanut butter soyafood almond

- le prix des granulats au benin

- money making guidemining iron ore

- mobile track mounted crushers