double toggle jaw crusher mechanism

Jaw Crusher Working Principle – Conmix Crusher

Conmix Single Toggle Jaw Crushers are uses only one toggle plate in its mechanism. Single toggle jaw crushers are provided in heavy and light versions with welded steel housing and a moving jaw in a welded or cast steel version, as well as an eccentric shaft made of highgrade forged steel.

Double Toggle Jaw Crusher Yagnam

Optimized Crusher cavity, effective nip angle, kinematics and operating parameters fully guarantee the excellent productivity for which YUGNAM double toggle jaws are known and valued. Cavity area is in accordance with the intake material Nip angle, which is critical for productivity and trouble free operation is maintained M each of the model.

journal on jaw crusher mechanism

review on design and analysis of jaw plate of jawcrusher ijirse. consideration of decreasing the weight of the swing plate of jaw crushers. ... on different factors like product sizeand mechanism used. ..... of jaw crusher plates", International Journal of Rock Mechanicsand Mining Sciences Geomechanics,.

Jaw Crushers Double Toggle Jaw Crushers Manufacturer ...

Roljack jaw crushers are the most productive and costefficient jaw crushers for any primary secondary crushing application. Jaw crushers were originally developed to crush the hardest ores and rocks so they perform extremely well also in less demanding applications, such as .

jaw crusher flywheel operating mechanism

Single Toggle Jaw Crusher Armstrong Equipment. Typical applications for our singletoggle jaw crushers are in mining ... duty parts for constant operation and long life. Each machine is backed ... running operation. Balanced flywheel and drive pulley. ... Hydraulic System. Toggle Mechanism.

toggle joint mechanism in stone crushers

mechanism stone crusher healthonthego. stone crusher mekanizmalarthe toggle mechanism is used in many forms in the plate is hinged at the bottom so the crusher always has the same size opening for the. Get More Info. image . Dynamic Analysis of Double Toggle Jaw Crusher Using Pro . dynamic analysis for the jaw crusher mechanism.

single toggle jaw crusher mechanism Solutions Kefid ...

single toggle jaw crusher mechanism ... Difference Between Single Double Toggle Jaw Crusher. Sep 20, 2014· In contrast, the single toggle jaw crusher has fewer shafts and bearings and only one toggle which goes from the bottom of the swinging jaw to a fixed point at the back of the jaw crusher. The eccentric is located at the top of the ...

Jaw Crusher Mechanism Work

Study of Kinematic and Dynamic Analysis of Jaw . This paper focuses on review of a work done by researchers in the field of kinematic and dynamic analysis . and the single and double toggle jaw crusher mechanism is

double toggle jaw crusher kinematics

Double Toggle Jaw Crusher BPA Engineering Equipments Pvt. Ltd. Offered Double Toggle Jaw Crusher is known for its fine jaw plates, high quality ... is propelled by two massive cast steel flywheels to apply the right kinematics,...

Vibrating Screens and Double Toggle Oil Lubricated Crusher ...

RCI Brand Double Toggle Jaw Crusher has longer life as compared to the jaw plates of other crushers, because RCI Brand Double Toggle Jaw Crushers work on the principle of "Crushing without rubbing". In this automatic, continuous spray lubrication is provided by coupling pump for the pitman toggle mechanism which enables the crusher to run safely.

Jaw Crusher ScienceDirect

DoubleToggle Jaw Crusher. ... θ= jaw angle. The mechanism of movement of rocks down the crusher chamber determines the capacity of jaw crushers. The movement can be visualised as a succession of wedges (jaw angles) that reduce the size of particles progressively by compression until the smaller particles pass through the crusher in a ...

double toggle jaw crusher kinematics SlideShare

Apr 11, 2015· double toggle jaw crusher kinematics 1. BinQ Mining Equipment double toggle jaw crusher kinematics, difference between single and double toggle jaw crusher, double toggle jaw crusher manual, animation of double toggle jaw plate crusher, jaw crusher double toggle set up, The Defference Between Double Toggle And Single Toggle Jaw Crusher, mechtech double toggle jaw crusher .

Industrial Solutions Jaw crushers

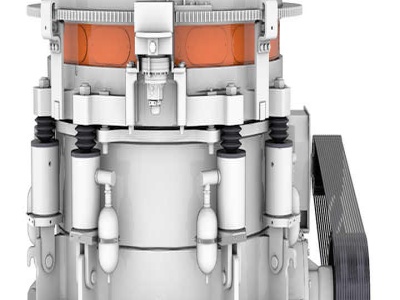

Doubletoggle jaw crushers are equipped with a doubletoggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, ... ing mechanism, making doubletoggle jaw crushers ideal for crushing the hardest, most tenacious materials.

Jaw Crusher | Primary Crusher in Mining Aggregate JXSC ...

Which jaw crusher better single toggle or double toggle? If you want to buy the jaw crusher machine, this article will help you to know the equipment. Jaw crushers are heavy duty machines and hence need to be robustly constructed. The movable jaw and static jaw are made up of the crushing chamber. It stimulates .

double toggle jaw crusher a

Jaw Crushers, Single Toggle Crusher, Double Toggle Crushers, SINGLE TOGGLE . The single toggle crusher is designed for a high capacity throughput due to the elliptical movement of the swing jaw which also assists in the discharge of the crushed material.

Double Toggle Oil Crusher | Sham Industries Vibrating ...

Double Toggle Oil Crusher. Sham Industries is manufacturer of Double Toggle Oil Crusher, Jaw Crushers, Double Toggle Oil Lubricated Jaw Crusher,Oil Bath Type Jaw Crushers,Double Toggle Grease Based Jaw Crusher, Jaw Crusher India.. For different application suitable MCM jaw crushers are available and these can be fitted to the plants without any difficulty.

single toggle jaw crusher mechanism

double toggle jaw crusher compared to single toggle type. Double Toggle Oil Type jaw crushers use two toggle plates in crushing process. mechanism of Doub. brand Double Toggle ... Crusher, Jaw Crusher, Single Toggle ... Chat Online

jaw crusher flywheel operating mechanism

Jaw Crusher Double Toggle Oil Type Sai Engineering Works. A small diameter light flywheel is necessary for low inertia of the mechanism. Operating Mechanism is totally enclosed for maximum life and minimum ... Jaw Crusher Oil Type Double Toggle Primary size 500 mm x .

COLLEGE OF ARCHITECTURE AND ENGINEERING .

jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates. This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle mechanism.

single toggle jaw crusher mechanism

Single Toggle Jaw Crusher, Milling Grinding Tools | A Single Toggle Jaw Crusher uses only one toggle plate in its mechanism. Two bearings are fit in the swing jaw of this crusher and the other two bearings support the. Contact Supplier

Papers by Keyword: Jaw Crusher

Abstract: This paper conducts a comprehensive study on the optimization design for crushing mechanism of double toggle jaw crusher. The optimization aim is to reduce characteristic value of moving jaw plate, to raise capacity of jaw crusher, and to ensure entrance and outlet dimensions of jaw crusher.

single toggle jaw crusher mechanism

Purpose: To obtain equations that can be used to describe the motion of any given point in the swing jaw of a single toggle jaw crusher. Design/methodology/approach: The swing jaw drive mechanism of a single toggle jaw crusher is modeled as a planar crank and rocker mechanism with the swing jaw as the coupler link. Contact Supplier

mechanism of jaw crusher pdf

double toggle jaw crusher mechanism . Crusher Wikipedia. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as ...

Latest Posts

- مصانع معالجة خبث الحديد فى مصر

- كسارة متنقلة مدير الشركة المصنعة

- كسارة الفك الصغيرة العراق

- سعر كسارة ذروة

- ارتفاع الناتج تأثير الفلسبار كسارة سلسلة pf

- مطحنة الكرة الفحم الولايات المتحدة

- مصانع معالجة الأحجار للكمبرلايت

- شرح مطحنة الكرة في الكانادا

- تاجر كسارة الحجر في اليمن

- mesin jaw crusher الجزائر

- خام القصدير فصل الجهاز

- جميع مصانع الطحن في اليمن

- سعر آلة حفر الاسطوانة

- معدات التعدين على نطاق محطم صغيرة غانا

- آلة قطع حجر المرمر

- moetso mobile cruser mechanical part

- inline leach pressure jigs china prices

- jaw crusher crwler

- raymond pabrik dan perbedaan ball mill

- stone crusher sand making machine in india

- high manganese and chrome castings

- price of vibratory sieve shaker

- 1200 gold grinding machine

- kapur penggalian mesin peralatan bbc

- ore dressing ore zimbabwe gold mill

- procedimiento de las trituradoras

- five roller mill roller design

- ultra wet grinder with timer price india

- simple spiral chutes

- cement price in abidjan grinding mill china