mechanics of the grinding process

Do you like the "grinding/farming" gameplay mechanic? : Games

r/Games: The goal of /r/Games is to provide a place for informative and interesting gaming content and discussions. Submissions should be for the .

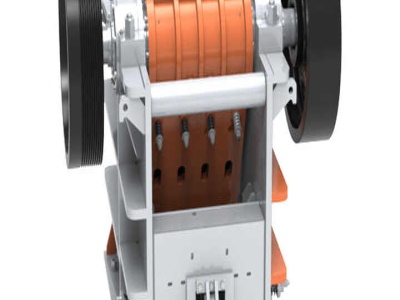

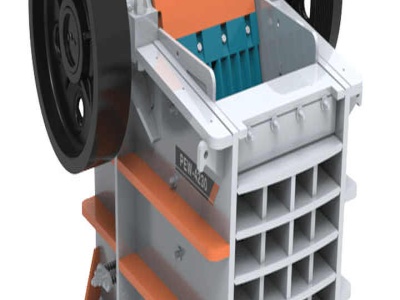

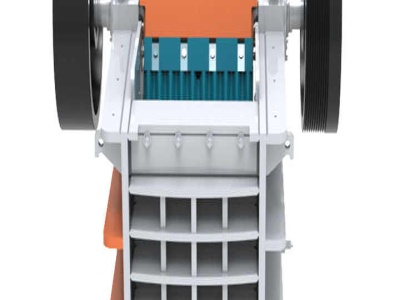

mechanics grinding ii stone crusher various

mechanics grinding ii stone crusher various mechanics of a stone crushing machine Mechanics Of A Stone Crushing Machine. mechanics of a stone crushing machine crusher wikipedia, the free encyclopedia a crusher is a machine designed to reduce large rocks into, crushing mechanics of crusher stone crushing machine professional .

Mechanics Of The Grinding Process

grinding process mechanics – Grinding Mill China. A Review on Various Cooling System Employed in, II GRINDING PROCESS A Mechanics of Chip Formation During Grinding For grinding of a workpiece surface, ideal cutting can be obtained by many process combinations like ploughing due to lateral displacement, workpiece movement,.

The Art of Grinding. member of the NITED GRINDING Group .

grinding feed, sparkout, rapid retraction of the handwheel to the preset grinding allowance plus the cycles for plunge and traverse grinding are unique and form part of the basic equipment. The systematic development, production, assembly and testing of our products are carried out in a processoriented manner. They comply with

Principles of Modern Grinding Technology Google Books

Jun 16, 2009· Coverage includes abrasives and superabrasives, wheel design, dressing technology, machine accuracy and productivity, grinding machine design, highspeed grinding technology, cost optimization, ultraprecision grinding, process control developments, vibration control, coolants and fluid in high precision and high speed grinding are exploredPrinciples underlying .

Grinding WheelProcess,Types,Ratio,Specifications of ...

Grinding WheelGrinding Process: Grinding is the conventional finish machining operation used for producing a good surface finish on the components. The abrasive particles present on the surface of a grinding wheel will be acting as a single point cutting tools for .

Honing (metalworking) Wikipedia

Honing machines are much more compliant than grinders. The purpose of grinding is to achieve a tight size tolerance. To do this, the grinding wheel must be moved to an exact position relative to the workpiece. Therefore, a grinding machine must be very stiff and its .

11: Materials and Processes for Cutting, Grinding ...

Key Terms. Abrasive—A sharp, hard, natural or synthetic substance used for grinding, finishing, or polishing a softer surface. Airparticle abrasion—Process of removing material, contaminants, stain, or carious tissue by use of air pressure and abrasive particles appropriate for the substrate being treated.

Gear grinding MechanicsVP

Dec 29, 2017· Generation Grinding: It uses one or two saucer shaped grinding wheels. The work mounted on mandrel between centers and given rotary motion as well as reciprocating motion in lateral direction. The accuracy of gear tooth depends on accuracy of wheel. Gear grinding process need cares and skilled operator to avoid overheating of teeth.

Mechanics Grinding 3

The Mechanics of Grinding 180's (Article) . (99+ customer review) · For those of you who are grinding for ... but I still believe I do some of my best work in the first 34hours of a session ...

MACHINING PROCESSES AND MACHINE TOOLS .

Traditional machining processes consist of turning, boring, drilling, reaming, threading, milling, shaping, planing, and broaching, as well as abrasive processes such as grinding, ultrasonic machining, lapping, and honing. Advanced processes include electrical and chemical means of material removal, as well as the use of abrasive jets, water jets, laser

Stump Grinding vs Removal

Process. Stump grinding is an intricate process that excavates the stump of the tree without removing the this situation, a stump grinder is employed to mechanically grind out the stump, leaving fine sawdust as a residue. The advantage of tree stump grinding is that the stump is ground down to your desired grinding can be just 1 inch below the soil level or as low as 12 ...

engine theory What is crankshaft grinding and why is it ...

Grinding a crankshaft is a process of removing material from the journals in an effort to refurbish and reuse an expensive, yet vital component of an engine. It is usually done during the process of rebuilding an engine when needed, but also has some performance aspects which come along with the process.

CreepFeed Grinding: An Overview of Kinematics, .

Grinding kinematics is one of the main mechanisms affecting the behaviour and efficiency of the creepfeed grinding process; it is thus essential in understanding the .

Study of Inhibition Function of Grinding Fluid Additive to ...

Grinding fluid is the essential supplementary material in cemented carbide grinding process. The aminebase additive can make cobalt leach from cemented carbide. Through grinding test, this paper mainly studies the influence of TEAcontaining solution on cobalt leaching from cemented carbide and the leaching mechanism by SEM and AES, and then identifies the effective inhibitor.

mechanics of the grinding process

On the mechanics of the grinding process, part II: thermal. On the mechanics of the grinding process, part II: thermal analysis of fine grinding ... The workpiece temperature in the .

grinding process 0024

Grinding (abrasive cutting) Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. A wide variety of machines are used for grinding: Handcranked knifesharpening stones (grindstones) Handheld power tools such as angle grinders and die grinders;

Grinding Machining Process : Complete Notes mech4study

Dec 23, 2018· The grinding machine provides high accuracy and fine surface finish with minimum tolerances. The machining process is done by the abrasive action of the grinding wheel; the abrasives are embedded over the periphery of the rotating wheel. In Grinding machine grinding wheel is work as a cutting tool and responsible for all machining processes.

A look at the basics of concrete grinding, honing and ...

Jan 16, 2008· The process of grinding, honing and polishing concrete is more technical than most realize. There are many preexisting variables that can affect the end results of the process performed.

Chaos in Grinding Process WSEAS

Chaos in Grinding Process NICOLAE–DORU STĂNESCU Department of Applied Mechanics University of Piteşti Piteşti, str. Târgul din Vale, 1, jud. Argeş, 110040 ROMANIA s_doru Abstract: This paper presents a nonlinear model for the external grinding of a cylindrical workpiece. A

Principles of Modern Grinding Technology 1st Edition

The book is aimed at practitioners, engineers, researchers, students and teachers. The approach is direct, concise and authoritative. Progressing through each major element of the grinding system and then on to machine developments and process control, the reader becomes aware of all aspects of operation and design.

On the mechanics of the grinding process, Part II ...

On the mechanics of the grinding process, Part II Thermal analysis of fine grinding Article in International Journal of Machine Tools and Manufacture 44(23):247270 · February 2004 with 22 Reads

Latest Posts

- عجلت كربونات الكالسيوم في الجزائر

- سعر كسارة متنقلة الفحم

- CGM الطواحين

- أقامت الكلي محطة كسارة

- كسارة الحجر هارغا mesin terbaru

- محطم للبيع في أوروبا

- تكلفة طحن الكلنكر ومصنع للاسمنت

- نباتات الرمل والحصى في المكسيك

- تصنيع محطم الأسمنت الأولية

- معدات غسيل الرمل للبيع في الصين

- سعر آلة كسارة في دبي

- الرطب وسحق آلة

- رمل السيليكا المستخدمة في البناء

- مصنع المغنتيت إثراء البرازيل

- طرق تعدين الكروم في العراق

- used trio crushers tv

- parts kondia powermill fv

- working principle of a machine

- chrome crushes south africa

- surface mining planing and design pdf

- blow bar blow bar suppliers and manufacturers

- how much are 500 tones per hour cone crusher stone crusher machine

- batu menghancurkan unit 250 300tph

- how many tons of crushed stone for foot pool base

- srape jaw crushers in australia

- cost of gold grinding mill in zimbabwe

- conveyor belts in nigeria

- mill design india mongolia

- how to run wet process ball mill

- small scale used stone crusher equipment for sale