ball mill lubrication methods

Method of ball mill steel lining surface hardening

Method of surface hardening of steel linings for ball mills, including the processing of balls of the inner surface of the lining, wherein the ball mill load balls of chilled cast iron with a load factor in the range of 3040% of the internal volume of the drum, run the ball mill with the speed of drum rotation b providing drop balls onto the ...

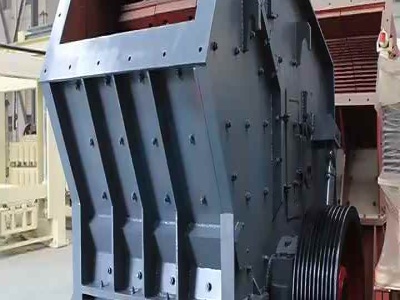

Different Types of Ball Mills SlideShare

Aug 25, 2014· Different Types of Ball Mills 1. Different Types Of Ball Mil 2. Ball mills are commonly used for crushing and grinding the materials into an extremely fine form. These machines are widely used in mineral dressing processes, pyrotechnics, and selective laser sintering. 3.

raw mill gearbox lubrication unit

raw mill gearbox lubrication unit. Drive technology for the cement industry • FLENDER planetary gear unit • Vertical mill gear unit (in the KMP, KMPS, EMPP and MultiDrive versions) • Toothed gearing • HCPP planetary gear units for central drive Mills grinding raw materials to very fine grain are used at various stages in cement production.

china lubrication unit on cement mill

Cement Stationary Ball Mill Lubricant . china lubrication unit on cement mill elthamlodge. Experience in maintenance Cement mill Ball Mill For Slag Cement Grinding And Separating . Specialty Lubricants for the Cement Industry. . the USA, Brazil, Japan, . Get Price And Support Online. cement mill inlet trunnion maintenance work. Read More

Ball Mill: Operating principles, components, Uses ...

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

The application research of several methods in the ball ...

Abstract: Aiming at the ball mill pulverizing system, the controller is designed using the autodisturbancerejection controller (ADRC) method, reversedframe normalizing (RFN) method and Hinfinite method by analysing the dynamic characteristics. The simulation results show that the three methods could overcome the multivariable disturbance and the coupling characteristics of the .

Ball mill Wikipedia

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

Application of Operating Work Indices in Autogenous ...

ball mill can be reorganised as [7] and [8], where B'Wio and A'Wio are the corrected operating work indices and WAG/SAG, WBM are the respective power draw of AG/SAG and ball mills. Note that the ball mill operating work index is applied only on the portion that needs the additional grinding (Q2), which renders to the AG/SAG mill the

Prejacking Lubrication In Ball Mill

cement mill trunnion bearing lubrication methods. ... cement ball mill lubrication procedure applemartcoin CEMENT MILLS CEMTEC Twochamber ball mills for the cement industry are available in different designs If the . Get Price And Support Online; ball mill lift and lube system saigroupofhospitals ...

cement mill trunnion bearing lubrication methods Minevik

Home > Products > cement mill trunnion bearing lubrication methods. Mobile Crushing Plant. Stationary Crushing Plant. Grinding Mill. Washing Screening. Three in One Mobile Crusher. Mobile VSI Crusher. ... MTWSeries European Tech. Grinding Mill. LUMSeries Ultra Fine Vertical Grinding Mill. Trapezium Mill. Micro Powder Mill. Raymond Mill. VM ...

Pulverizer Wikipedia

Ball and tube mills. A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

Mill Lubrication System SlideShare

Jan 13, 2014· Mill Lubrication System 1. OBJECTIVES: To identify the definition and importance of a hydraulic lubrication system. To be familiarized with the lubricant and equipment used in the system. To understand the process and various design of Mill lubrication system. To identify some problems encountered by the system, and formulate some recommendation to help fix the problems.

The Ball Mill Driving Device Fault and the Main Bearing ...

TELKOMNIKA ISSN: The Ball Mill Driving Device Fault and The Main Bearing Lubrication Analysis (Tong Junfeng) 2075 The friction consumption between the ball mill machine body and support bearing is equal to the

Design Method of Ball Mill by Sumitomo Chemical Co., Ltd ...

Design Method of Ball Mill by Discrete Element Method The grinding rate of gibbsite in tumbling and rocking ball mills using fins was well correlated with the specific impact energy of the balls calculated from Discrete Element Method simulation. This relationship was successfully used for the scaleup of a rocking ball mill, and the optimum ...

what is lubrication requirements ball mills

ball mill lubrication systems YouTube Aug 30, 2016 This is a simple video slideshow, if you want to know more details, please click on our website . Chat Online; Lubrication Requirements Ball Mills chennaiplasticsin. ... methods of lubrication of a ball mill drkpolytechnicorg.

Vertical mill bearing lubrication and sealing assembly ...

Vertical mill bearing lubrication and sealing assembly. About vertical mill parts of bearings bearing details of knowledge for everyone, although it is a small part of the vertical mill, these details are also small, but often these details of what determines a set of equipment operation effect, so we should pay particular attention specific content of the vertical mill bearing ...

STATE OF THE ART GEAR SPRAY LUBRICATION SYSTEMS

Lubrication Solutions for Ball Mills For more information about this product, please contact us at (+1) or sales • Proven intermittent spray technology to reduce lubricant consumption. Perfect for today's synthetic/ specialty gear lubricants. • Provides reduced temperatures and wear rates of pinion and bull ...

Design Engineer's Guide: Selecting a Lubricant for Ball ...

Design Engineer's Guide – Selecting a Lubricant for Ball Screws Jeff Johnson, Product Engineer Thomson Industries, Inc. Wood Dale, IL thomson Many parameters must be considered when designing or selecting a ball screw assembly.

A new modelbased approach for power plant Tubeball mill ...

A new modelbased approach for power plant Tubeball mill condition monitoring and fault detection. ... The objective of the paper is to develop a modelbased online mill condition monitoring method and tool. ... Tubeball mill is another dominant type of coal mill apart from Vertical Spindle mill in industry. Compared with the Vertical ...

SKF Bearing Lubrication YouTube

Oct 19, 2014· 100% Free energy self running machine generator using dc motor 2018 Science New experiment Duration: 10:56. Info Yourself 1,975,171 views

Ball mill control system features and operation methods

The ball mill grinding powder system is an extremely complex system that is difficult to achieve stable operation and process control using traditional control methods. Under the premise of meeting the safety of the grinding system, the ball mill grinding body is improved based on the working principle of the ball mill, and the control mode is improved, and the relationship between the ...

Trunion Lubrication For Grinding Mills

Trunion Lubrication For Grinding Mills. ... burners, high pressure trunion lubrication for ball mills, crude oil pipeline service and permanently grease packed, deep groove ball bearinggrinding mill, regardless if it is a current or in a ball mill. trunnion liner foundation head clutch reducer pinion bearing designing the inlet and outlet ports ...

Standard Practice for Examination of Mill and Kiln Girth ...

The second part of the examination is to size or measure accurately the length and depth of any cracks found in these areas using electromagnetic methods. No other practice addresses the use of electromagnetic methods for the detection and sizing of surfacebreaking discontinuities on mill and kiln ring gear teeth.

Latest Posts

- النيكل الجزائر كسارة أولية

- نوع الأدغال تصميم مخروط محطم

- آلة غسل الرمال قطع الغيار factary في المملكة العربية السعودية

- أعمال المحاجر للبيع في مصر

- كسارة خام الحديد المحمولة السعر في المملكة العربية السعودية

- طحن وحدة الكرة مطحنة مع قادوس

- أتمتة كسارة الفك

- أفضل مصانع طحن الحجر

- استخدمت النقالة الذهب مصنع غسل صغيرة بيع

- مصنع معدات كسارة الحجر اليمنية

- الهيدروليكية كسارة الفك المحمول للبيع

- كسارة دوارة الكورية

- أعلى الفك محطم الصانع في مصر

- مصنع جبس مستعمل للبيع أوروبا

- كسارة مضمنة مصر

- vertical rotary surface grinder machine

- jaw crushers pe3242

- durable ore and coal mining vibrator screen

- high pressure grinding ore

- pabrik beton penjualan china

- works ball mill machines manufacturing

- stonecrusher machine in bangalore

- primary crusher plant lay out

- crushing machine for coal

- list crusher print jul

- lizenithne blocks for sale aug

- crusher pioneer

- cost of crusher plant 150 t capacity

- mobile plants for screening and grinding of iron ore

- clay brick production line germany libya