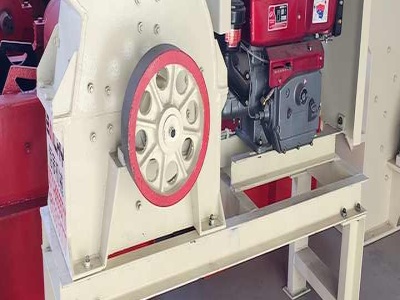

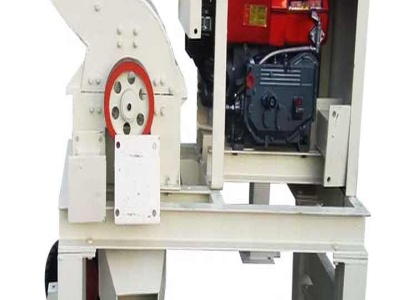

mounting in grinding machine

Grinding Wheels, Wheel Adapters, Quills | Precision ...

Grinding Wheel Adapters, Grinding Wheel Hubs and Flanges. Standard, special and custom precision grinding wheel adapter – standard taper adapters – inch TPF with 1 inch diameter at large end of taper Cincinnati taper grinding wheel adapters – inch TPF with inch diameter at large end of taper Special taper wheel adapters for:...

Grinding Wheel Safety: Respect The Maximum Speed

Mar 15, 2003· Mounting the grinding wheel on a sander, such as a "pistol grip" air sander; Mounting the wheel directly on an electric motor; Mounting the wheel on the wrong machine size for that wheel; Failing to properly maintain machine components, particularly governors on pneumatic machines and linkages on floorstand machines

INSTRUCTIONS HOW TO USE A MILLING MACHINE

The plain vise, similar to the machine table vise, is used for milling straight workpieces and is bolted to the milling machine table either at right angles or parallel to the machine arbor. The swivel vise can be rotated and contains a scale graduated in degrees at its base to facilitate milling workpieces at any angle on a horizontal plane.

Wavecut Grinding Machine / WGM | ChrisMarine

Portable machine for insitu wavecut grinding. WGM has been specifically developed to provide cylinder liners with a tribologically superior surface known as wavecut pattern. The pattern enhances lubrication and reduces attrition. Thanks to the mounting adapters on top of the machine, is selfcentering, stable and accurate. WGM – product features

mounting of filtration system in grinding machines

oil mist collector / filtration media / machinemount MistEliminator PLYMOVENT ... A fan impellor or cyclonic system separates the oil mist enabling most of the ... oil mist filters installed on machine tools as lathes, grinding machines, milling . Get Price

Engineering Skill II: LAB 3 GRINDING MACHINES

If two or more grinding wheels are used to complete internal grinding, true each wheel after mounting it to the spindle of the internal grinding attachment. SURFACE GRINDING Surface grinding or grinding flat surfaces, is characterized by a large contact area of the wheel with the workpiece, as opposed to cylindrical grinding where a relatively small area of contact is present.

Planar Grinder Machine PlanarMet™ 300 | Buehler

The Buehler PlanarMet 300 is a planar grinder machine is ideal for planar grinding of metallographic specimen preparation. Our planar grinder machine uses a high torque motor.

9 advantages of CNC vertical grinding machines

A DMG MORI pallet changer on a vertical grinding machine. Horizontal grinding machines have traditionally come with a higher cost of ownership when compared to vertical ones because horizontals have all of their precision axes and spindles in the coolant contamination zone. Grinding swarf accumulation in and around the linear axis and wheel spindles is unavoidable.

Service Machines: Graf + Cie AG

Service Machines. For Flat Cards and Roller Cards. ... GAV, Metallic wire mounting equipment for flat cards up to a 60" working width. ROD 35, Roller mounting equipment for groove and surface wound roller. ROD 35/1 Roller mounting equipment for surfacewound rollers. ... DSM 20 stationary flat grinding machine for flat types of 37" to 40 ...

PPT – Grinder Use Safety Training PowerPoint presentation ...

Common Causes of Grinding Incidents. Using the wrong wheel for the job or grinder ; Improper mounting of wheel or guard ; Careless handling ; Repetitive motion ; Improper PPE use ; Improper use of grinder; 8 Critical Grinder Wheel Safety Issues. Some Grinding wheels can be surprisingly delicate. They can be easily damaged if handled carelessly.

Mini Lathe Tool Grinding

This was a help when grinding your tools, as you did not have to grind any back rake into the tool itself. When grinding threads tho, a neutral back rake angle is desirable, thus one had to grind a negative rake angle (point of tool pointed downward) to compensate for the positive back rake angle built into the tool holders.

Cutting Tool Applications Chapter 16: Grinding Wheels and ...

Grinding pressure: Grinding pressure is the rate of infeed used during a grinding operation; it affects the grade of wheel. A general rule to follow is that as grinding pressures increase harder wheels must be used. George Schneider, Jr., is the author of Cutting Tool Applications, a handbook to machine tool materials, principles, and designs ...

Generating grinding and profile grinding KX 300 P | KAPP NILES

In addition to the mainly used cylindrical grinding worms, single or multiset CBN profile grinding wheels can be used for fullform machining as an alternative. A total of six NCaxes align the gear wheel and tool with each other.

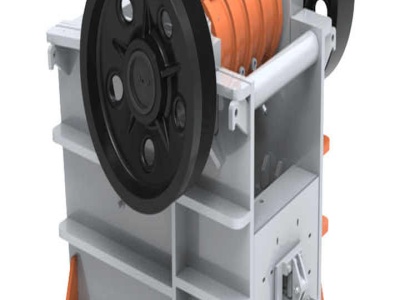

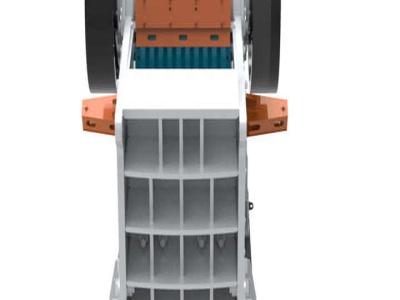

Valve Grinding Machines | Lapping Machines | Climax Portable

Valve Grinding Lapping Machines. Lightweight for easy handling and installation, our valve grinding and lapping machines span working ranges for gate valves from to inches (32 to 1000 mm). During operation, you can quickly change grinding disks and adjust the grind pressure. Solid construction, sealed lubrication...

Operator's Manual: Grinding Machine, Valve Face, Bench ...

Operator's Manual: Grinding Machine, Valve Face, Bench Mounting, 9/32 Inch to 11/16 Inch Chuck, 0 to 45 Degree Valve, Face Angle Adjustment, 115volt, AC/DC, 60cycle, Single Phase (Cedar Rapids Model "KWIKWAY" KK) (). Department of the Army technical manual: Contributor: United States. Dept. of the Army: Publisher

9 advantages of CNC vertical grinding machines Aerospace ...

Aug 09, 2017· A DMG MORI pallet changer on a vertical grinding machine. Horizontal grinding machines have traditionally come with a higher cost of ownership when compared to vertical ones because horizontals have all of their precision axes and spindles in the coolant contamination zone. Grinding swarf accumulation in and around the linear axis and wheel spindles is unavoidable.

ATM Metallography / Materialography manufacturer website

ATM GmbH is a worldleading manufacturer of machines for metallographic analyses: Cutting, mounting, grinding, polishing and analyzing technologies.

Mounting grinding

Custom Machine Tables Precision Grinding Inc. Precision Grinding manufactures custom steel machine bases Rather than mounting new machinery on a plain concrete floor, machine manufacturers may recommend mounting large equipment onto a machine base or a floor plate. Chat online Cutting Mounting Grinding and Polishing Consumables

Latest Posts

- معدات نوع جبس جبس في السعودية

- مصنع مطحنة الكرة 5ton للساعة الواحدة من الصين

- تستخدم آلة سحق الباريت في الولايات المتحدة الأمريكية

- مكينة طاحونة جديدة للبيع في العراق

- ركام الخرسانة المسحوقة

- التعدين الحجر وخطة عمل المحجر

- مطحنة كروية لطحن الأسمنت في مصر

- سحق المحمول وإعادة تدوير مصر

- طاحونة هارجا ميسين

- م تصنيع الرمال سعر الجهاز

- تقنيات لمعالجة خام في نطاق ضيق

- مطحنة الحجر الجيري مطحنة الكرة tph

- العراق - العراق

- لفاف و الكسارات مخروط

- كسارة وأو رقائق الرخام

- alpine grinding mill manufacturer

- gurgaon naurangpur stone crushers unit

- materials and a peeling potato chopper

- what is the average price of a portable rock crushing machines

- gold dredge jet flare

- t h crusher plant desien coal russian

- menghancurkan penjualan bijih kromium proses crushing

- chima golden mining sac

- stone crusher brisbane

- m crusher sand and powder

- mining jack hammer price

- all over the word famous brand for crusher

- rail grinder track

- volume tinggi penghancur bijih besi

- insmart system jaw crusher