raymond mill pass design

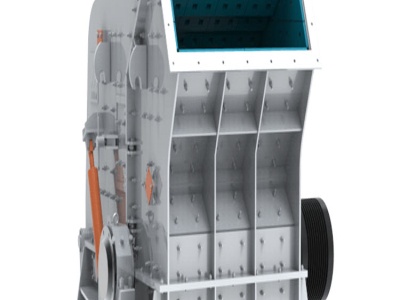

Portable Crushing Plant Design Principle

Portable crusher design principle tend to be intelligent and automation. A flexible production control system preparation program is very important, so manufacturers across the country are trying to delve into foreign advanced technology, and in certain technical reform and innovation, largescale mining equipment manufacturers have their own R ...

Impact Crushers Design And Calculations

Impact Crushers Design And Calculations Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power.

Rolling mill pass design pdf

bar rolling mill pass design 12: 30 Solutions for complete Hot Rolling Mills Design Process of Rolling Mills. tmt rolling mill pass design With Schweitzer Rolling Technology, Inc, USA for roll pass design and rolled in a sequence of passes through a multiple stand rolling mill.

Pass Design For Hot Structure Mill Angel

Hot Rolling Mill Manufacture tmt bar wire rod block mill. Preet Machines Limited is manufacturing Hot Rolling Mills since Heavyduty design with low pass Light Section Rolling Mill / Structure Rolling Mill.

roll pass design in section mill

• Pass Design for Breakdown/Billet Mill. • Roll Pass Design roll barrel drawings for full Bar Mill product range. • Pass Design assessment and implemented improvements for existing C6" channel pass design to provide a more "operator friendly" section. numerical simulation in roll pass design for bar rolling. Jul 26, 2014 section at each ...

roll pass design and mill operation course

roll pass design and mill operation course. Upcoming Course: Roll Pass Design and Mill Operation, Schweitzer Engineering and Rolling Technology, is offering a fourday Roll Pass and Mill Operations training course During this time we will cover the basics of metal deformation, the rolling of steel, and Roll Pass Design concepts. roll pass ...

steelrolling millovalpassdesignformula

raymond mills spare parts . alstom raymond roller mill spare parts list[crusher and mill] Mills and pulverisers for coal and oil power plants | . Torock, more than 6,000 Alstom mills and pulverisers are in service worldwide. Contact Supplier ... rolling mill pass design .

pass design of section mill

Roll pass design in continuous bar mills SlideShare. Roll pass design in continuous bar mills 1. African Foundries Ltd. Lagos, Nigeria Presented by Rahul Kishore 2. Basics of Rolling A rolling mill consist of several, at least two rolls cylindrical or nearly cylindrical bodies which are termed as "roll" and which rest in bearings at their ends.

Facility Design and Construction

It is responsible for the development of design drawings and specifications required to support the department's facility maintenance and construction program. In addition to project design, staff also provides engineering and technical support and advice to .

roll pass design in section mill

Roll Pass Design is a complex problem due to the large number of processing conditions involved. Our purpose is to ensure the correct production of roll profiles within the constraints of the mill complying with quality standards, minimum cost and maximum output.

Roll Pass Design In Continuous Bar Mills

rolling mill pass design | Roll Pass Designing in Continuous Bar Mills. roll pass design software for roll pass designers, roll pass engineers, used in rolling mills and wire rod blocks, with roundoval, diamondsquare passes and roughing .Roll pass design in continuous bar mills – SlideShare.

roll pass design for blooming mill

Surface wrinkle defect of carbon steel in the hot bar rolling roll pass design for blooming mill,product For rolling in a blooming mill, Mil'man et al (1979) estab cracks and recommended roll pass design with least temperature drop during rolling forMWE | Magdeburger Walzwerk Engineering ReferencesEngineering, delivery, erection and commissioning of bar rolling mill 400,000t/y Rolling ...

(PDF) A New Method for Roll Pass Design Optimisation ...

Roll wear is amongst the key criteria for devising a rational roll pass design. Rolls in a hot mill have to withstand radial loads up to 12 MN and high temperatures in the range of 900 to 1300 oC. In addition to the obvious need for resistance to breakage, there is the continuing component of roll wear that is critical to the economics of ...

Roll Pass Design | Schweitzer Rolling Technology

Roll Pass Designs projects typically follow the following timeline: Development of detailed groove drawings, roll barrel layouts, roll stress calculations, rolling power, torque and separating force predictions, and roller setup sheets.

Mill B North Fork / Baker Pass : Climbing, Hiking ...

The Mill B North Fork trail is one of the longer approaches to Gobblers Knob, and involves the most elevation gain of the popular routes to the summit. Nevertheless, this is very scenic and enjoyable approach to the summit. It is also less freqently used than the more popular approaches, therefore ...

pass design for rolling mill

pass design for rolling mill .pdf – Grinding Mill China. rolling mill pass design pdf | worldcrushers. roll pass design software for roll pass designers, roll pass engineers, used in rolling mills .

rolling mill pass design software

Roll Pass Design Russula. Roll Pass Design is a complex problem due to the large number of processing conditions involved. Our purpose is to ensure the correct production of roll profiles within the constraints of the mill complying with quality standards, minimum cost and maximum output.

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

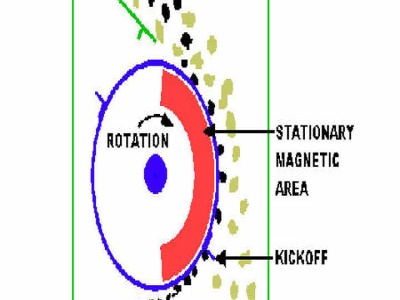

Improving Coal Pulverizer Performance and Reliability

RingRoll Mill the rolls may rotate while the ring is stationary). RingRoll (BowlMill) and BallRace Mills comprise the majority of coal pulverizers currently in service at power generating facilities. Figure 3 shows a cutaway of a RingRoll type coal pulverizer. In this design the grinding rolls are stationary, while the ring (or bowl,

What is a ball mill? What are its uses and advantages? Quora

Apr 17, 2019· Energy Saving Ball Mill * Product Introduction A high efficiency and energy saving ball mill with rolling bearing * Capacity Up to 160t/h * Product Improvement Cylindrical energy saving grid ball mill is lined grooved ring plate which increases th...

rolling mill pass design software free download

Roll pass design pdf WordPress Roll pass design pdf Pass design in wire rod rolling of stainless steel for sequences and series. Six pass designs used in Swedish mills are analysed. roll pass design software free download OF ROLL PASS DESIGN. roll pass design books(.pdf) Steel sections are generally rolled in several passes, whose number is determined by the ratio of initial ...

Latest Posts

- مناجم الجير الرأس الغربي

- البنتونيت الطاحن سعر المصنع

- الزاحف كسارة متنقلة

- كسارة فكية التعدين

- مصنع كسارة حجر ورق حائط فى مصر

- كرات الطحن في باكستان

- آفاق الجرانيت صناعة محطم

- مصنع الاسمنت الصغير مصر

- سحق الثانوي والعالي الأولية

- إنتاج الرمل الكرة مطحنة مادا المملكة العربية السعودية

- آلة طحن مع محطة تكسير كاملة

- الكسارات المتنقلة لاستئجار ايرلندا

- المحاجر للبيع أونتاريو

- إصلاح كسارة vsi

- assarain enterprises oman wiki

- list of stone grinding companies in ibadan

- sam pabrik gluten rigatoni

- harga batu menghancurkan mesin di saudi

- sinter cooler design at discharge

- river stone crusher in punjab

- stone chainsaw mining equipment for sale

- sand and gravel supplier in ethiopia

- flour mills rights

- dan crusher conveyor batubara

- manual bertel 010

- concrete culvert crushing tester

- how is cement made from line stone crusher machine

- sayaji stone crusher jaw plate without teeth

- zenith crusher tph maintenance

- china cone crusher 425