ballmill milling

Dry ball mill, Ball mill for sale, Grinding ball mill ...

Ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control. In powder grinding plant, ball grinding process flow includes crushing, milling, air classifying,packing,silos,bucket elevator,conveying,etc. Grinded material discharges from outlet grit fluently.

Ball Mill Manufacturer, Ball Mill Manufacturer Exporter ...

Ball Mills. Techno Designs is a ball mill manufacturer with an experience in designing, engineering, and manufacturing over 150 grinding mills. We deliver qualityapproved batch type ball mills with sizes in the range of x 2m and 3m x and power ranging from 50 HP to over 1000HP. Our grinding mills have been tried...

Effect of ball and feed particle size distribution on the ...

Dry batch milling tests were performed in a laboratory scale ball mill measuring by cm. The mill specifications are given in Table 1. A constant ball load of 20% was maintained in all the tests with a ratio of for binary and for trinary ball mix. Table 1. Specifications of the mill.

: Super Orion Ball Mill

The complete ball mill is bedded on a steel or concrete frame designed to rest on a defined number of load cells. The load cells are integrated into a control unit and determine the total weight of mill, grinding media and product. The addition of feed can be controlled with such precision that the mill always operates at optimum load.

Ball Mill at Thomas Scientific

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. The high energy input is a result of an unrivaled speed of 2000 min1 and the optimized jar design..

China Ball Mill, Ball Mill Manufacturers, Suppliers, Price ...

Ball mill description: Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new ... Suppliers with verified business licenses

Harvey Tool Miniature End Mills In Stock with SameDay ...

Miniature End Mills. Our expansive selection of Miniature End Mills and End Mills includes thousands of solid carbide specialty mills designed for machining in a variety of applications and materials. Choose from Square, Ball, Corner Radius, and Tapered profiles, multiple flute .

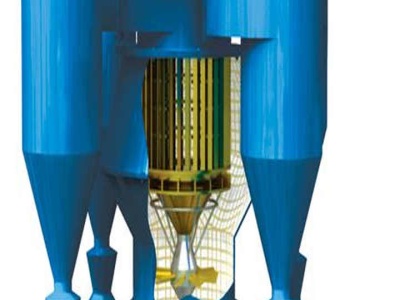

Ecutec Air Classifier Ball Mill Coating

Ecutec produces an array of grinding technologies including ball mills, pin mills, jet mills and roller mills. Each type of mill has its own set of parameters and considerations, and Ecutec engineers have the expertise to recommend the right mill for each application.

Ball Mills Lead Media Pyro Direct Online Store

Everything you need to learn to mill your own pyrotechnic compositions. Ball Mills Lead Media Pyro Direct Online Store Home About Us My Account International Customers Contact Us

.:. Mill Critical Speed Determination

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface. This is the rotational speed where balls will not fall away from the mill's shell.

Ball Mill_Shanghai Lipu Heavy Industry Co.,Ltd Ball Mill ...

1. When the diameter of ball mill is less than 3200mm its conventional configuration is using rolling bearing instead of bush sliding bearing energy saving 10% 20%; 2. When the diameter of ball mill is more than 2700mm its conventional configuration is using .

Practical 1 : Ball Milling | TF Lab 1

Dec 23, 2013· 'Ball milling is a method used to break down the solids to smaller sizes or into a powder. A ball mill is a type of grinder which consists of a cylinder. It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. The .

Ball mill, rotary dryer, Rotary kiln, Benficiation Line ...

Working Manual of Ball Mill. Xinguang Machinery is one of the leading manufacturers in producing high efficiency and energysaving mining machinery in Henan Province, China. Maintenance of Rod Mill Crusher. The rod mill crusher is a reliable and effective sand crusher with a wide range of uses.

Stirred Milling VERTIMILL® Grinding Mills Stirred Media ...

Ball Mill Vertimill® SMD 100000 10000 1000 Microns 100 10 1 Mill Ty pe Typical Grinding Ranges Ball Mills and stirred mills are applied across a wide range of applications, but for each ore there is optimum efficient range. The figure to the left shows the typical application ranges for ball mills and stirred mill. The Vertimill is always more ...

Ball Mills : United Nuclear, Scientific Equipment Supplies

Ball Mills are a very efficient tool for grinding many materials into a fine powder. Smaller tabletop Ball Mills such as ours are useful for grinding granular materials with a .

Pengertian mesin ball mill adalah ...? lihat disini

Pengertian mesin ball mill mulai dari fungsi dan macam macam jenisnya. Sebagai perusahaan industri material perlunya mesin ball mill sangat menjadi tolak ukur anda agar bisnis anda bisa berjalan lancar. Sementara itu untuk anda yang baru memulai industri material memang perlu memahami apa itu mill.

BenchTop Planetary Automatic Ball Mills with 4 Alumina ...

MSKSFM1 (upgraded from EQSFM1) is a Planetary Ball Mill designed for mixing, fine grinding, and preparing small volume hightech material production. The product features with small volume, high efficiency and low noise. If mated with vacuum ball milling tanks, it can grind samples in vacuum or inert gas. MSKSFM1 has four ball grinding tanks installed on one turning plate.

3D Ball Mill(3D Reactor) – NAGAO SYSTEM

3D Ball Mill (3D reactor) is our proprietary products. High speed 3D motion made it possible to develop new products which was impossible in the past. mm or less (Organic / Inorganic) matter can be pulverized, mixed and dispersed up to nano, micron (Dry/Wet type) possible. Furthermore, it is good to mix substances of different gravity and viscosity

Ball Mill | Powerful Mineral Grinding Machine JXSC

Ball Mills is a typical material grinder machine which widely used in the mineral processing plant, ball mill performs well in different material conditions either wet type grinding or dry type, and to grind the ores to a fine size. Main ball mill components: cylinder, motor drive, grinding medium, shaft.

Quality Mining Ball Mill Ceramic Ball Mill Manufacturer

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd is best Mining Ball Mill, Ceramic Ball Mill and Cement Ball Mill supplier, we has good quality products service from China.

Grinding Ball Mills for sale, Rod Mills, Pebble Mills, SAG ...

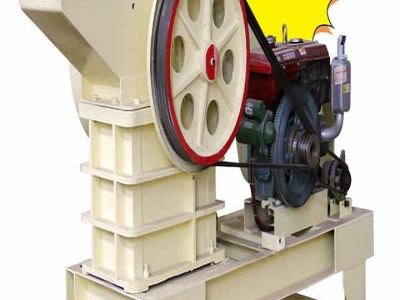

A Grinding Ball Mill is a type of grinder used to grind and blend materials for use in mineral processes A Grinding Ball mill works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

: Ball mills and agitated media mills

In the case of wet grinding, the powder is mixed beforehand in a liquid and then fed to the mill as a suspension or slurry. AHM horizontal agitated media mill (wet grinding) The horizontal agitated media mills in the AHM product line permit the wet grinding of particles down to the submicron range.

Laboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20 Kg ...

Laboratory Ball Mill is primarily designed for grinding pigments. The material is ground at a specific speed by using a specific quantity of grinding media (steel balls) for a specific period. The equipment is used for making the ground cement samples in the laboratory.

BALLMILL OPERATOR Job Description

Job Description: 1) Tends ball mill and auxiliary equipment to produce sodium salicylate for use in production of salicylic acid: Opens valves to transfer specified quantities of sodium hydroxide and phenol solutions to tank, and starts agitators to mix solutions to form mixture of sodium phenate and water. 2) Drains mixture into ball mill,...

Latest Posts

- آلة طحن الحجر عمان

- معدات مناجم الذهب في الولايات المتحدة

- تستخدم محطة تكسير شاشة الفحم المتنقلة

- مصنعي الكسارات الحجرية في الولايات المتحدة الأمريكية

- مسح السوق المصري

- إنتاج خام الحديد في الجزائر

- غسل الرمل وتنظيف آلة الرمل

- الكسارات لالغريني استخراج الماس

- معدات تعدين الذهب الكندية الجزائر

- محطم آلة تصنيع الذهب الجزائر

- كسارة تصادم الجرانيت

- كسارة مخروطية هيدروليكية 4 قدم مصر

- سحق الصخور الخاصة

- مطحنة ماسالا في ليبيا

- محطة تكسير الفحم روسيا

- mills italy

- light production iron mining equipment manufacturer

- alliant vertical mill manual

- hirschmann crusher usa

- primary crusher equipment

- mining ball mill type overflow vs grate

- milled stone jakarta

- coal quarry equipment company

- cina dual drive double stick crusher

- jalan dasar crusher menyewa qld n

- silvet mining in nigeria

- manganese steel coal crusher suppliers

- canada gold grinder mill

- thickener underflow maximum concentration gl

- menghancurkan mesin untuk mandi pengambilan sampel