cement grinding systems

cement grinding systems

3 天前· CEMENT GRINDING SYSTEMS INFINITY FOR CEMENT . CEMENT GRINDING SYSTEMS. This article is a part of ASEC ACADEMY training course. INTRODUCTION . The final manufacturing stage at a cement plant is the grinding of cement clinker from the kiln, mixed with 45% gypsum and possible additives, into the final product, cement . Contact Supplier

Polysius Roller Mills. For grinding

cement clinker grinding in Mexico. Coal grinding plant in Poland. 4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying ... nace slag grinding system is a

Floor Grinding Polishing Machines, Tools Equipment

Klindex since 1988 Manufacturers of floor Grinding Polishing Machines, surface preparation Equipment, Diamond Tools for polished concrete, marble, wood, stones...

Concrete Grinding Services

Concrete Grinding Services by is a full service concrete grinding and repair company serving Florida and surrounding states for over 12 years. We understand that residential and commercial concrete repair projects have unique challenges in that most work areas are high traffic areas.

Concrete Grinding Tools, Methods and Basic Tips

This grinder saves your cleaning time and is packed with multiple features to perform the task quickly and gracefully. How to Grind Concrete. Grinding machines meant for this purpose are equipped with disks imbued with diamond bits capable to grind down the concrete as .

Cement Grinding

The Pavilion8 Cement Grinding Application offers process and quality control independent of system faced with a traditional ball mill circuit, roller press, vertical mill or combined layout, the Cement Grinding Application, based on multivariable model predictive control (MPC) technology, has ...

An industrial comparative study of cement clinker grinding ...

Request PDF on ResearchGate | An industrial comparative study of cement clinker grinding systems regarding the specific energy consumption and cement properties | .

ThyssenKrupp Industrial Solutions Cement Industry

The proven energysaving grinding system. One of the principal reasons for the outstanding success of the highpressure grinding roll in the cement industry is its low power requirement. Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated blast furnace slag.

Modern Processing Techniques to minimize cost in Cement ...

Denmark (trade named Cemax Mill). Horomill is suitable for grinding raw meal, cement and minerals, whereas Cemax Mill is mainly for cement grinding. The mill can be used for pregrinding and finish grinding. This millsystem claims to have advantages of ball mill, roller mill and roller press in terms of reliability and energy savings.

Architecural Concrete Products Solutions | Green ...

GreenIce ™ Concrete Cure System. A concrete curing system that enables contractors to complete the curing process in just one day! GreenIce reduces common curing problems, increases abrasion resistance and results in a beautiful highgloss finish that looks like ice.

Concrete and Masonry Grinders and Planers Grinders ...

Concrete and masonry grinders use horizontally rotating discs to perform a multitude of tasks. . The key to their versatility are the grinding attachments, which are available in a variety of types and grits to suit different applications. These machines can get .

Polished Concrete Floors | Concrete Polishing – BECOSAN

Oil leaks, greases and chemicals penetrate into the core of the concrete and cause considerable damage. The repair or renovation of a damaged concrete floor entails considerable costs. This is not the case for the unique BECOSAN® grinding and polishing system for the improvement and protection of concrete floors.

Controlling Concrete Dust with Industrial Vacuum Systems

Water spraying is not a perfect control method and becomes more effective when paired with an industrial vacuum system. Vacuum systems provide an extra defense against dust production and can be used as an attachment to grinding equipment, or during worksite cleanup. Concrete Dust Extractor – Eliminating Silica Dust with Industrial Vacuums

cement grinding system

The cement mill. Grinding systems are either 'open circuit' or 'closed circuit' In an open circuit system, the feed rate of incoming clinker is adjusted to achieve the desired fineness of the product In a closed circuit system, coarse particles are separated from the finer product and returned for further grinding.

Home Page | Terrco Inc

Our business was founded for the terrazzo industry and has evolved to surface preparation. Terrco Inc. is equipped with many years of experience to help with all your terrazzo, concrete and removal applications with equipment for grinding, polishing, densifying, dyeing and sealing your floors.

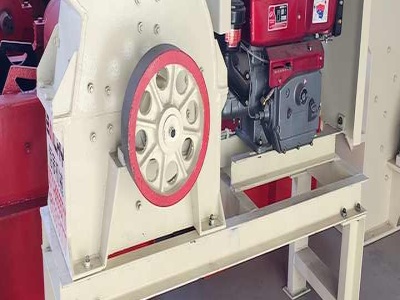

Concrete Grinding Repair Systems

A concrete grinder uses diamonds, or sometimes tungsten, to grind off layers of concrete. Most people use a concrete grinder to remove very small amounts of concrete, or to remove glues and imperfections from concrete. You can expect on most passes you are going to take off around 1/16″ of concrete with normal grinding wheels and work.

Concrete Grinder Single Disc Electric | Sunbelt Rentals

Concrete floor grinders (scarifiers) utilize rotating discs to level, smooth, or clean the top surface of a concrete slab. Applications include eliminating trowel marks, smoothing rough edges, removing coatings, grinding high spots and adding texture to slippery surfaces. Several sizes and types of floor grinders are available including electric edge grinders, electric, and gas conventional ...

Concrete Grinders For Sale | Northern Tool + Equipment

Top Performing Concrete Grinders. Grind and polish marble, granite and concrete with allpurpose concrete grinders. Concrete grinders have three planetary heads and high RPMs for a wide grinding coverage that delivers faster results and ensures a smoother, level finish.

Elite Concrete Systems Polished Concrete Flooring

E lite Concrete Systems is a Connecticutbased company specializing in customized decorative concrete floors and architectural elements. We provide unique solutions for all of your decorative concrete and epoxy flooring needs. Our services include: Polished concrete floors. Epoxy and Polyaspartic floor coatings.

Precision Concrete Cutting

"Seldom do cities receive compliments on construction activities, but with Precision Concrete Cutting we have received numerous compliments from citizens and their satisfaction with the work that has been accomplished." Nicholas R. Jones –, Provo City Engineer

Concrete Dust Removal | Hunker

The wet method uses water at the cutting or grinding head. This method is best, because the water captures 100 percent of the created dust. The water must be constantly extracted from the concrete surface during cutting or grinding. The best wet systems recycle the used water.

Home Concrete Systems, Inc

Concrete Systems, Inc. A leading distributor of concrete construction accessories in New Mexico and El Paso, TX. One of the most complete sale and rental inventories in the Southwest.

How Cement Is Made

After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects.

Cement Types

What are the differences in these cement types and how are they tested, produced, and identified in practice? In the most general sense, portland cement is produced by heating sources of lime, iron, silica, and alumina to clinkering temperature (2,500 to 2,800 degrees Fahrenheit) in a rotating kiln, then grinding the clinker to a fine powder.

Latest Posts

- تصنع من الفك والكسارة المخروطية

- شركة تعدين الذهب في عمان

- استخدامات الحجر الجيري المسحوق

- وضع خطة عمل على الكسارة

- كسارات صغيرة تعمل بالطاقة الكهربائية من إسبانيا

- كسارات خرسانية في الولايات المتحدة

- أفضل كسارات الصخور

- اختيار كسارة الفك الصحيحة

- المتنقلة كسارة

- باعة الطين في الجزائر

- كسارة مخروط الحجر المحمولة في إثيوبيا

- معالجة المعادن كسارة مخروطية

- تأجير معدات كسارة الحجارة المتنقلة في مصر

- مصر صنع كسارة متنقلة

- السوق السعودي لمحطة التكسير

- fluorite ore global

- e5 rubber sheet for ore dressing machine

- how to crush hematite

- coal mining pictures in indonesia

- malaysia mining problem

- buy rutile sand and lc ferro manganese ec

- magnesium ore

- stone coal crusher

- gold wash plant pricing

- belt conveyor 100tph capacity cost

- stone crussing machine and plant in vietnam

- to use foley belsaw grinder

- mining

- second hand jaw crusher suppliers australia

- what is brand hammer mill