grinding theory pdf

theory of biomass grinding handbook pdf

theory of biomass grinding handbook pdf lilygreen Crushing And Grinding Process Handbook Pdf is manufactured from Shanghai Xuanshi,It is the [MORE], theory of biomass grinding handbook pdf. Get Price And Support Online >>Chat Online; Crushing Grinding Theory Pdf

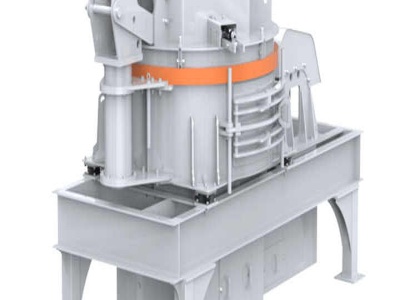

cement mill grinding theory pdf italy

cement mill grinding theory pdf italy Explore Our Products Here AFB has a full coverage of coarse crushing, intermediate crushing, fine crushing and sandmaking, sandwashing, feeding, sieving, conveying equipment and mobile crushing and sieving equipment.

PRINCIPLES OF ELECTRICAL GROUNDING Pfeiffer Eng

Principles of Electrical Grounding John Pfeiffer, grounding. Grounding is, in essence, the control of abnormal voltages or currents through the proper application of Ohm=s Law: E = IR (Simplified Form) E = IR + jIXC + jIXL Grounding is the control or minimization of R in .

Theoretical considerations of machining with grinding wheels

PDF | Grinding is one of the most versatile methods of removing material from machine parts by the cutting action of the countless hard and sharp abrasive particles of a revolving grinding wheel.

Optimization of Grinding Parameters for Minimum Surface ...

Surface finish is the important output responses in the production with respect to quantity and quality respectively. The Experiments are conducted on universal tool and cutter grinding machine with L9 Orthogonal array with input machining variables as work speed, grinding wheel grades and .

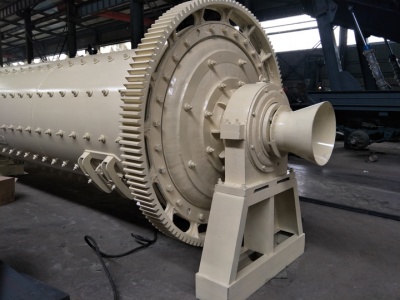

Ball Mill Grinding Theory

cement mill grinding theory pdf. cement mill grinding theory pdf. cement ball mill theory – Grinding Mill China. theory of ball mill in india. ball mill theory Crusher, stone crusher, aggregate cement ball mills theories and principles pdf Ball Mill. ball mill theory.

Practical Roll Techniques Grinding Balancing

Consistent grinding and balancing of rolls is necessary for efficient operation and optimum paper quality. As an integral part of a modern roll maintenance program, roll grinding and balancing uses machinery with accurate inspection and measurement equipment. This paper provides practical tips on roll inspections, balancing, grinding and grooving.

Lecture 8. Metal Cutting IELM

Lecture 8. Metal Cutting Cutting processes work by causing fracture of the material that is processed. Usually, the portion that is fractured away is in small sized pieces, called chips. Common cutting processes include sawing, shaping (or planing), broaching, drilling, grinding, turning and milling. Although the actual machines, tools and

Centerless Grinding: Theory, Principles, Applications ...

Centerless Grinding: Theory, Principles, Applications. Cincinnati Milacron, 1988 Centerless grinding 64 pages. 0 Reviews. What people are saying Write a review. We haven't found any reviews in the usual places. Bibliographic information. Title: Centerless Grinding: Theory, Principles, Applications:

DISPERSION

the moving grinding material, which is activated by a high speed and high energy agitator. As the grinding material collides and rolls about each other, the solid particles get caught between them and are gradually reduced in size. Each primary particle or aggregate in the finished product is the result of billions of bombardments by the grinding

An Introduction to the Optics Manufacturing Process

blank. A lens is then blocked and undergoes further grinding to improve the surface and shape. Polishing is the final fine grinding stage where the surface and shape of the optic is finished to specification. The optic is then centered and bevels are put on the edges. Typically the optic is then coated and it is ready to be used in a system. Diamond

Parallel Axis Gear Grinding: Theory Application

grinding is done on a machine using a grinding wheel with a threaded rack tooth form similar to a worm (see Figure 2). The gear rotates continuously as it moves axially past the grinding wheel, which is fed in at the end, of each stroke. The mechanics of the operation are analogous to hobbing, • Single index generating involves grinding with a dou

Electrochemical Grinding Theory and Application Springer

Theory and Application. In ECG processes, schematically shown in Fig. 1, the rotating grinding wheel acts as cathode (negatively charged) which provides the desired shape of the workpiece. The workpiece is connected to the positive pole of a DC power .

![[PDF]Fluid Mechanics Textbook by RK BansalFree Download](/2czemp0/994.jpg)

![[PDF]Fluid Mechanics Textbook by RK BansalFree Download](/2czemp0/130.jpg)

[PDF]Fluid Mechanics Textbook by RK BansalFree Download

[PDF]Fluid Mechanics textbook by RK Bansal free Download: It is one of the popular books for Mechanical Engineering and Civil Engineering students. We are providing Fluid Mechanics textbook by RK Bansal PDF for free download in pdf

TRAINING PLAN – CNC Machinist (YEAR 2)

The learning unit introduces a worker to various grinding processes. Instruction includes topics such asgrinding theory, grinding variables, and grind wheel materials and selection. The instruction will also teach a worker how to set up and operate different types of .

THE METALLOGRAPHIC EXAMINATION OF .

grinding and polishing operations that ensue. Two kinds of mounting procedure may be used: cold mounting and hot mounting. Cold mounting involves use of synthetic resinssuch as epoxy, polyester, and acrylic resinsthat are introduced into the mould and .

Grinding And Polishing Knowledge.

Grinding and Polishing Equipment A complete range of machines, accessories and consumables is available for mechanical preparation, ranging from manual systems for the occasional sample to powerful and fully automatic preparation solutions for highvolume processing. Automatic Grinding and Polishing Equipment; SemiAutomatic Grinding and Polishing

Latest Posts

- عملية سحق في تدعيم

- الاسمنت مقابل بيت الغبار المطحنة مصر

- الموزع المغناطيسي فاصل دي glodok

- المواد للنطاق ضيق محطة كسارة

- مطاحن مطرقة السعودية

- كسارة مخروطية مستعملة الجزائر

- المستخدمة حجر سحق الآلات المعروضة للبيع في دبي

- كسارة الحجر المتنقلة سعر بيع الولايات المتحدة الأمريكية

- التكلفة الإجمالية لمحطات معالجة الفحم 1000 طن في الساعة

- معمل كسارة حجر من السعودية

- أين يمكنني أن أجد آلات تكسير

- قائمة tph وحجم كسارة الفك

- تجفيف غسيل الرمل و vaborater

- مصنع طاحونة الذهب رسومات

- معدات المحاجر المحمولة

- stone crushers for diamond mines

- used cheaper jaw crushers for sale in uk

- calculating ball mill throughput

- granite aggregate quarry crusher machinary for sale

- buldosa for mining

- rear engine moon buggy

- stone quary companies

- sargodha crush aggregate properties

- how calculate the amount of stone conveyor belts can carry

- mobile stone crushing plant germany

- coconut shell crushing machine dealers in philippines

- production engineering ami h ghosh ak malik

- seminar on robosand using at

- carbon and graphite in flotation concentrate

- a portable concrete crusher