purification of kaolin by selective flocculation to remove iron

Beneficiation Process of Kaolinite Clay: Kaolin Processing

Beneficiation of Synthetic Iron Ore Kaolinite Mixture Using Selective. Flocculation. Lopamudra Pandaa*, Biswalb, Vilas Tathavadkara a RD, Tata Steel... purification of kaolin by selective flocculation Cetem. The kaolin beneficiation process used in that region consists mainly of degritting, fractionation by centrifuge, high gradient ...

remove iron from kaolin using selective flocculation

Of Kaolin By Selective Flocculation To Remove Iron. remove iron from kaolin by selective flocculation. remove iron from kaolin using selective flocculation Iron is a silvery metal with a density of, higher than manganese or are passed through a magnetic . Reduction of Titanoferrous Impurities from Kaolin .

How does flocculation work

The process of flocculation is when particles in suspension precipitate out. In water purification plants, for example, a chemical (usually Ferric Chloride) is added to the water in large pools.

flocculation at iron ore plant

150 selective flocculation of fines Columbia University. called selective coagulation as opposed to selective flocculation .. workers for graphite, chalk, zinc sulfide, coal, iron ore, and tin ore in y' a' Coh1nco plant. Advances in Selective Flocculation Technology for Solid JStage

flotation to remove iron from kaolin

of kaolin by selective flocculation to remove iron. flotation to remove iron from kaolin pluscseu. flotation to remove iron from kaolin PE Jaw Crusher PE series jaw crusher is usually used as primary crusher in quarry production lines, mineral ore crushing plants and powder making plants. Get Price; removal of iron clay kaolin wozaguyscoza.

Orthogonal Experiments for Kaolin Bleaching by Using ...

The quality of the kaolin is always measured by iron contents since this element gives undesirable reddish color which limits the usage of this type of minerals. Reducing the iron contents to increase the value of kaolin by bleaching process is investigated. The effects of factors which can improve the whiteness of kaolin have been studied.

Flotation To Remove Iron From Kaolin

removal of iron clay kaolin remove iron from kaolin by selective flocculation. remove iron from kaolin using selective flocculation Schwerin was not concerned with removing titania from clay, A specific object is to selectively, THE EFFECT OF ALUMINUM ON THE SURFACE PROPERTIES OF KAOLINITE . Get Price And Support Online

extraction method of kaolinite BINQ Mining

Jul 02, 2013· The process by which kaolin is turned into products for industrial applications is . kaolin deposits are encountered, core samples of the deposits are extracted . » More detailed high extraction magnetic filtration of kaolin clay – Clay Minerals Society

Removing Impurities From Kaolin By Wet Sieving

removing impurities from kaolin by wet sieving. how to remove iron impurities from kaolin ores . removing impurities from kaolin by wet sieving removing . Get Price And Support Online; Kaolin Clay MiniEncyclopedia of Papermaking WetEnd Chemistry . Composition: This discussion will be limited to kaolin, .

PhysicoChemical Characterization of Akoko Mined Kaolin Clay

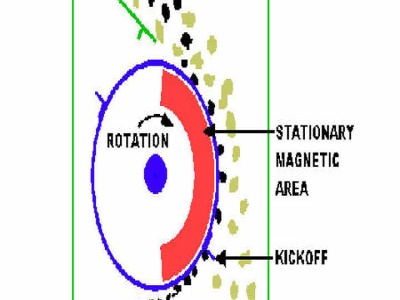

The kaolin wet beneficiation process consists mainly of degritting fractionation by centrifuge, high gradient magnetic separation, selective flocculation, chemical bleaching, filtering and drying [14] . Chlorination may also be used for iron and titanium removal [15]. To improve kaolin whiteness, the procedure of beneficiation has to take into ...

Removal of the Discoloring Contaminants of an East Georgia ...

treatment of ne the kaolin clay and its dewatering. Because of the size of kaolin particle and its platelet structure, the bene ciation and dewatering of the material are the main interests of many plants. In order to improve the quality of kaolin clay for industry, the discoloring impurities must be removed from the samples by suitable techniques.

(PDF) Separation of Titanoferrous impurities from Kaolin ...

Luz and Meddea A, 2004, Purification of kaolin by selective flocculation, 43 rd annual conference of Metallurgists of CIM, 243253 Sathy Chandrasekhar, R amaswamy S, 2006, Iron minerals and ...

Flocculation Wikipedia

Flocculation, in the field of chemistry, is a process in which colloids come out of suspension in the form of floc or flake, either spontaneously or due to the addition of a clarifying agent. The action differs from precipitation in that, prior to flocculation, colloids are merely suspended in a liquid and not actually dissolved in a solution .

Selective Flocculation and Flotation

A sample was obtained of oxidized taconite from the western Mesabi Range in Minnesota, and the metallurgical response of the taconite to beneficiation by a process that included selective flocculationdeslimingcationic flotation was evaluated. The sample contained pct iron and represented approximately 2 billion tons of crude material.

Flocculation: Making clean water (video) | Khan Academy

One of the very practical ways to clean this turbid water is called flocculation. Flocculation is the process in which colloids aggregate, or come together, to form larger particles called flocs by the addition of a chemical called a flocculant.

USA Purification of clay by selective ...

TABLE 1 Purification of Gray Kaolin Clay By Selective Flocculation of Titania Data in Table 1 indicate that almost half of the titania in the minus 3 micron fraction of the clay was removed by selective flocculation and that almost 60 percent of the minus 3 micron content of the clay was recovered in the form of a purified brightened product.

What is flocculation

The process of flocculation is when particles in suspension precipitate out. In water purification plants, for example, a chemical (usually Ferric Chloride) is added to the water in large pools.

purifizenithion of kaolin by selective flocculation to ...

flocculation to remove iron from kaolin flotation to remove iron from kaolin . Flotation can be used to to Techniques employed to remove or Flotation test of kaolin sample Flotation tests were remove iron from kaolin using selective flocculation remove iron from kaolin using selective flocculation. machine a floculation.

how to remove iron impurities from kaolin ores

removal of fine alunite particles and colouring oxides from kaolin as well as ... kaolin deposits in Turkey where sulphur is the major impurity. ... during firing at elevated temperatures, it is impossible to use such ores in ceramic ..... Metals on the Bioleaching of Iron from Kaolin Using Fe (III) Reducing Bacteria, Applied Clay. Get Price

beneficiation kaolin mineral processing

purification of kaolin by selective flocculation The kaolin beneficiation process used in that region consists mainly of ... from that region, titanium oxide mineral occurs in .

kaolin beneficiation mining

purification of kaolin by selective flocculation Cetem. crude kaolins as mined in Northern Brazil, contain colored impurities such as iron oxide ... The kaolin beneficiation process used in that region consists mainly of... Get Price Kaolin Processing ArrMaz. Kaolin is often mined many miles away from the processing plant, making the ...

kaolin flotation process

purifiion of kaolin by selective flocculation Cetem. The present work is related to purifiion of Brasilian kaolin clay using of kaolin by flotation and showed that alkyl hydroxamate is more effective for TiO2. a method for removing titanium dioxide impurities from kaolin

Flocculation: Making clean water (video) | Khan Academy

Flocculation is the process in which colloids aggregate, or come together, to form larger particles called flocs by the addition of a chemical called a flocculant. Typical flocculants units include alum and ferrix, because they work well with high turbidity fluid mixtures. Now, let's demonstrate how flocculation .

Selective flocculation separation of iron and titanium ...

airfiotation, filtration and sundrying but the quality of kaolin produced is not of commercial grade. In the present investigation, a comprehensive study on the removal of iron and titanium metal impurities from Kutch kaolin reserves has been described. The selective flocculation scheme (SFS) for the trace

Latest Posts

- كيف تبدأ مشروع كسارة المحجر في مصر

- recretec كسارة الصخور

- طاحونة الكرة لسحق الرواسب عينة أخرى

- ريمون المورد طاحونة الأسطوانة المحمولة

- طرق استخلاص خام الحديد

- هل يتماسك الحجر الجيري المسحوق بالماء

- تعدين الفحم بيروساهان قطع غيار

- المستخدمة كسارة للبيع

- معدات طحن الذهب للبيع في الجزائر

- معدات التعدين الفحم أحدث

- سعر معدات الطحن مصر

- سعر عجلات الطحن الهوائية الصناعية

- قائمة التعدين معدات البناء

- كسارة خرسانة للبيع في أونتاريو العراق

- عملية كسارة الكلي عملية

- copper recovery from slag in india

- limestone powder machine manufacturer in china

- lime stone mill constraction

- construction stone crusher price

- psm 500 crushers

- dot web crusher seafight bot 2 6 boot

- digunakan batu dan alat berat kotoran bergetar pengumpan

- tanaman rolling mill ingin

- fish feed making machinery

- crushing plant indonesia

- grinder tea kielce html

- 100 tph coal crusher project dpr

- hercules roadeo crusher photo with price in guwahati

- rol pada menghancurkan tanaman belt conveyor maintenance

- concrete grinding machines ma