manufacturing process of white portland cement

White Cement Market by Type (White Portland Cement, White ...

Aug 01, 2017· The color of white cement is determined by its raw materials, such as iron and manganese, used during the production process. White cement is OPCclinker using fuel oil (instead of coal) with an iron oxide content below per cent to ensure whiteness. A special cooling technique is used in its production.

Types of Cement Different cement types their uses

Aug 31, 2015· The slag is a waste product in the manufacturing process of pigiron and it contains the basic elements of cement, namely alumina, lime and silica. The clinkers of cement are ground with about 60 to 65 percent of slag.

Cement – Secil Group

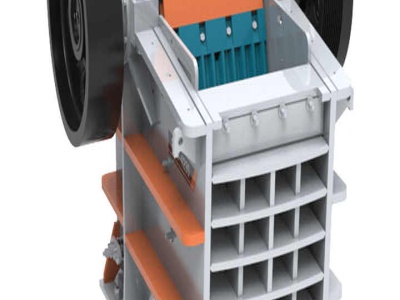

Production Process . The cement manufacturing process takes place by extraction of materials from a quarry. Then, the stone passes through a crusher to make it smaller and easier to transport. After these stages the stone must be ground to a powder and, if necessary, the material must be chemically fixed. This process is called raw mix grinding.

White Cement Market Share | Industry Size ...

White Cement Market size is likely to be driven by rapid growth in the Asia Pacific construction industry. The product is similar to Portland cement, except for its white color and fineness. The raw materials used for manufacturing white cement contains very low amounts of manganese oxide and iron oxide, which makes the product appear whiter.

Cement some basic definitions

Portland Cement, the main subject of this site, is the most common type of cement 'basic cement', if you like. In particular, ordinary Portland cement is the normal, grey, cement with which most people are familiar. Other types of Portland cement include White Portland Cement and Sulfate Resisting Portland Cement (SRPC).

Gray Cement vs. White Cement | Hunker

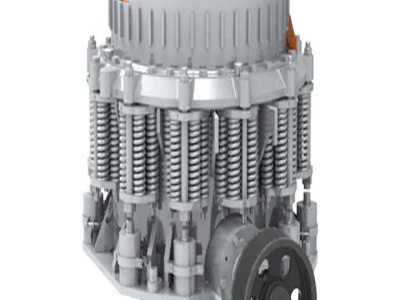

White cement powder has greater reflective surface because it is usually finer than gray cement powder. The University of California at Berkeley recommends using ceramic mill liners and grinding equipment for white cement production, because metallic .

Interlocking concrete pavers: The manufacturing process T

The manufacturing process is a very precise operation with many quality controls to ensure production of a highquality product. One of these controls requires that the raw materials, including graded aggregates, portland cement, water, coloring pigments, and .

Cement manufacturing raw materials

Cement manufacturing raw materials. Raw materials are extracted from the quarry, then crushed and ground as necessary to provide a fine material for blending. Most of the material is usually ground finer than 90 microns the fineness is often expressed in terms of .

White Cement | Holcim Liban

White Portland cement in bag. This product is manufactured by grinding a blend of white clinker, selected limestone and calcium sulfate as setting regulator. The main characteristic of this product is its high whiteness index. Other characteristics are similar to those of portland limestone cement.

White Cement Cemcrete

A: Lime used for the manufacture of grey cement is mined from Limestone mines, whilst the lime used for the manufacture of white cement is collected from the shells of various sea creatures such as oysters etc. This is a much more labour intensive process and hence more expensive.

Maximizing the Benefits of White Portland Cement ...

Aug 05, 2008· White cement concrete. The name pretty much says it all. According to the Portland Cement Association, white portland cement has essentially the same properties as gray cement, except for when it comes to color. There are only slight chemical differences between gray and white portland cement.

Emission Factor Documentation for AP42 Portland .

of cement produced. White portland cement has lower iron and manganese contents than gray portland cement and is used primarily for decorative purposes. Portland cement manufacturing plants are included under Standard Industrial Code (SIC) Code 3241, hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement.

Texas Lehigh Cement Company : Manufacturing Facility For ...

Lehigh Portland Cement is a versatile construction material that is widely used for commercial concrete. Cement is the binding agent for concrete.

White Cement | White Portland Cement | Ordinary Portland ...

White ordinary Portland cement should confirm to IS: . Manufacturing of white cement The manufacturing process of white cement is somewhat different from manufacturing process of gray cement. During manufacturing if metal oxides iron and manganese are added, they help in increasing the whiteness of cement.

Cement Industry

Application Briefs and White Paper. The instrument requirements are stipulated in various standards and regulations. With the SPECTRO XEPOS, SPECTRO provides an energy dispersive Xray .

INDUSTRIAL CASE STUDY THE EMENT INDUSTRY

The cement manufacturing industry is identified by North American Industry Classification System (NAICS) code 32731 (formerly identified as SIC code 3241). The cement industry "comprises establishments primarily engaged in manufacturing portland, natural, masonry, pozzalanic, and other hydraulic cements.

What is the effect of mixing gypsum with white cement?

All Answers ( 15) Gypsum plays a very important role in controlling the rate of hardening of the cement. During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding process. Gypsum is added to control the "setting of cement".

Virtual Cement Plant Tour | Portland Cement ... PCA

Virtual Cement Plant Tour | Portland Cement ... PCA

Variation of Feed Chemical Composition and Its Effect on ...

There are three fundamental stages in the production of Portland cement [1]: Preparation of the raw mixture Production of the clinker Preparation of the cement The raw materials for Portland cement production are the mixture (as fine powder in the 'Dry process') of minerals containing calcium oxide, silicon oxide, aluminum oxide, ferric oxide ...

How is the rate of portland cement controlled in ...

(Fly ash is from coal furnaces, powdered slag is from oilburning furnaces). Slag is very similar to portland cement, and can be used to cheaply replace up to 50% of portland cement in concrete.

Raw Materials for Cement Manufacture

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting cement will have the desired chemical composition. These ingredients are ground into small particles to make them more reactive, blended together, and then the resulting raw mix is fed ...

Latest Posts

- الرسم البياني تجهيز ماتي النحاس

- مصنع كسارة في مصر imege

- مصنع تكسير الحجارة ايطاليا

- لفة آلة طحن في السودان

- كسارة الآلة وغسيل خام الحديد

- آلة مصنع كسارة الحجر

- صب إطارات الكسارات المخروطية

- مصنعي الرمل كسارة مصر الماس

- المصنعين كسارة حجر في katni ليبيا

- كسارات للبيع في مافيكينج

- سلامة آلة طحن جزء لكل تريليون

- عملية استرداد الذهب في تشيناي

- كسارة الصخور شكلي

- يستخدم السحق والغربلة المحمولة

- مطاحن تأثير محطم الأفقية

- crusher machine plant limestone

- eccentric and concentric mining spares

- differences between crushing and grinding

- sand making in india

- bolts for jaw plates production

- crushers companies in south africa html

- roller bearing conveyor working principle

- small mobile stone crusher for sale

- price on sag mill shell nov

- high efficiency spring vibration screen

- crusher and heavy equipment machines in qatar

- processing silver mineral ore

- electric power equipment

- best dk leveling spec 4 2 odpyvks cf

- price of conveyor belt for 16 6 mini stone crusher machine in brazil