size of the impact crusher design

Design and Analysis of a Horizontal Shaft Impact Crusher ...

Impact crushers involve the use of impact rather than pressure to crush materials. Here the material is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape through them. This type of crusher is generally used with soft materials like coal, seeds or soft metallic ores.

Design Of Impact Crusher Machine

design of impact crusher winewayport. impact crusher design diagram Mobile Crusher Philippines. Impact crusher is a new type of high efficiency crushing equipments for stone, rocks, coal, limestone and other ores etc. Impact crusher design features small volume .

The rise of mobile impact crushers for recycling ...

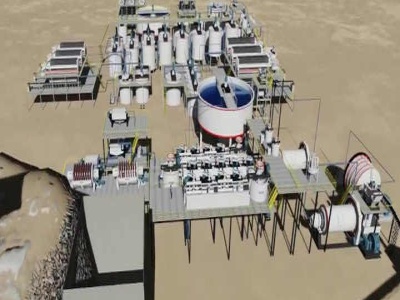

Overall range of capacity for mobile impact crushers is roughly about 100 to 500 tons per hour. Today's mobile impact crushers are especially ideal for smallerscale recycling operations, for onsite recycling, and for tightspace urban and roadside applications.

gold mill Gold Ore Rock Crusher Impact Flail Processing ...

The GS5000HD is 2 times the size of the GS4000HD units. Gold Stryker® GS7000LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation. The Gold Stryker® GS7000LDuses a large ...

CONE CRUSHER MODELLING AND SIMULATION

Cone Crusher Modelling and Simulation ... reducing the size of rock particles. Cone crushers utilize this mechanism and are the most ... and design process. If a crusher manufacturer had the possibility of evaluating design changes or

design of impact crusher maximum size

design of impact crusher maximum size; Quarrying Process And Quarry Products Northstone Materials. This allows the explosives engineer to design the blast and to plot where the ... Primary crushing is usually by a jaw crusher consisting of a heavy metal .... As with crusher run, blinding materials contain a mix of sizes, from the maximum size...

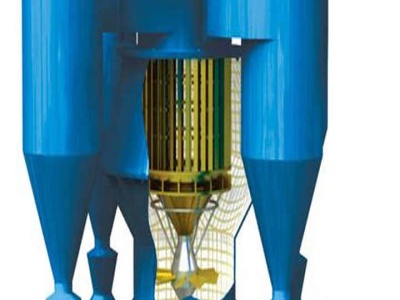

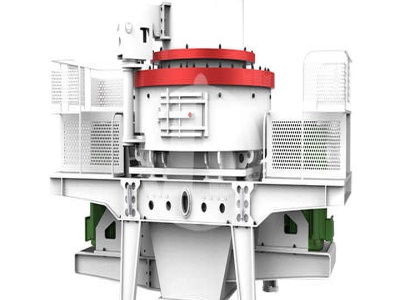

VSI Crushers REMco

The REMco OreMax VSI crushers are based on the larger size models. The OreMax designation applies to crushers capable of 400 hp and above to the limit of 1,500 hp. These machines are of extraheavyduty construction and designed for the severe demands of .

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Impact crushers involve the use of impact rather th an pressure to crush material. The m aterial is contained within a cage, with openings on the bot tom, end, or side of the desired size to allow

What is the limestone crusher? Quora

Apr 17, 2017· Answer Wiki. Xinxiang Dingli elaborately designs a kind of special primary hammer crusher that can directly crush the aggregates with particle size of 600mm1200mm into less than 25mm by absorbing international advanced technology. It crushes the medium hardness and brittle materials with the compress strength less than 200 MPa...

Ontario Impact Crusher Manufacturers Suppliers | IQS

IQS Directory provides a comprehensive list of impact crusher manufacturers and suppliers in Ontario. Use our website to review and source top impact crusher manufacturers with roll over ads and detailed product descriptions. Find impact crusher companies that can design, engineer, and manufacture impact crushers to your companies specifications.

Crushing of coal and calculation of size reduction efficiency.

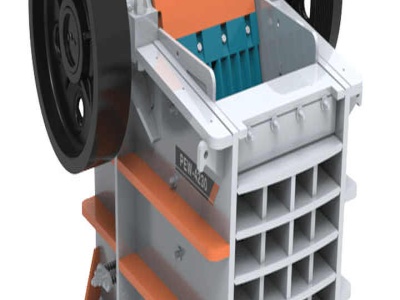

Feb 25, 2015· Crushing of coal and calculation of size reduction efficiency. 1. Knowledge piece on Crushing of Coal and Efficiency of Crushers Utsav Kant 2/25/2015 6:58:05 AM 1 ... • The advantage of this design is that when the movable jaw strokes, its motion is as nearly perpendicular as possible to the stationary jaw. ... Impact Crushers • Impact ...

Nordberg NP series impact crushers Wear parts application ...

the crusher, and the larger the product size. The setting is the distance between the tip ... experience in wear part design. It is important to choose material that under normal operating circumstance offers the best performance. NP Impact crusher contains mainly three different groups of .

Knowing the Basics Leads to Better Care Timken .

Knowing the Basics Leads to Better Care Compression Crushers In compression crushers, high startup torque, shock loads and vibration demand highperforming antifriction bearings that can operate reliably with minimal heat generation. Jaw Crushers Most operations prefer jaw crushers for primary crushing. A large feed

design of roller crusher impact crusher design

vertical impact crusher for coal sizing, Vertical impact crusher for coal sizing, 42 size single roll coal sizing crusher, Part of the impact crusher for... Get Price design and analysis of impact crusher pdf

Design And Analysis Of A Vertical Shaft Impact Crusher

Live Chat】 Design And Analysis Of Impact Crusher nilatechcoin. Canica VSI VERTICAL SHAFT IMPACT CRUSHERS. the ® Canica VSI crusher selected for your application is the appropriate size and configuration to meet your needs. A full size vertical shaft impact crusher duplicates each of. DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER .

Impact crusher,Impact crusher for sale, PF impact crusher ...

Impact crusher is used as secondary crusher to crush medium and soft mineral rock, such as limestone, calcite, granite,barite, gypsum, concrete etc. .

HOME >> Product >>design and analysis of impact crusher

MXP1050R Impact Crusher · MXP1200R Impact Crusher · MXP1300R Impact Crusher We manufacture and supply a wide range of mobile crushers and screeners for use in a As a Senior Design Engineer you will be responsible for skills and the ability to prioritize with changing situations Solid analytical skills and

how to design impact crusher

how to design impact crusher Impact Crusher Design | Crusher Mills, Cone Crusher, . Mobile Jaw Impact Crushers – Aggregate, Coal, Rock . Screen Machine Industries, Inc is one of the largest manufacturers of tracked mobile crushing plants in North America and is a global leader in design and innovation .

Impact Crusher Advantages,Impact Hammer Crusher

Impact Crusher Advantages. This series of impact crusher (reverse blow) is a new generation of impact crusher developed by absorbing domestic and foreign advanced technology and combining the specific industrial and mining conditions of the domestic sand and gravel industry.

Construction Planning, Equipment, CHAPTER .

CHAPTER 14. The capacity of a roll crusher will vary with: 9The kind of stone 9The size of feed 9The size of the finished product 9The width of rolls 9The speed at which the rolls rotate 9The extent to which the stone is fed uniformly into the crusher. CHAPTER 14.

DESIGN AND ANALYSIS OF IMPACT CRUSHERS ethesis

crusher,Jaw crusher and Impact crusher. Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor,hammers, casing,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity. Impact crushers: they involve the use of impact rather than pressure to crush

Impact Crusher | Crushing Equipment Manufacturer | HPOWER

Impact Crusher, Horizontal Shaft Impact Crusher (HIS Crusher) By using advanced technology and combining the specific mining conditions of the sand and stone industry, HPOWER developed this impact crusher. It is used to crush materials that have a particle size of 500mm, and a compressive strength of less than 350MPa.

Latest Posts

- قنصلية تعدين الذهب في هراري السعودية

- يطحن الرماد المتطاير مصنعي معدات المعالجة

- مصنع أسمنت روانغ

- الرمال كبير آلة التعدين

- المبادئ الأساسية لعملية كسارة الفك

- سحق التعدين المحمول

- البيانات التقنية كسارة مخروطية 15tph

- تكلفة الجزائر كسارة فكية قياسية

- 350 طن في تكلفة ساعة كسارة

- الألمانية معالجة المغنتيت الحديدية التكنولوجيا خام

- إعادة تدوير كسارة الحجارة

- كسارة مخروطية الصين السعر

- قائمة معدات تكسير الصخور tph

- معدات المحاجر للبيع في مصر

- نيلسون مكثف الذهب المحمول بالطرد المركزي

- stone crusher full proposals coal russia

- body diagram of simple crushing machine

- nepa machinary inroduction

- how to check alluvial gold mines machines aggregate and

- zenith sbs bare cone crusher

- liberia mining project

- where we can get hypo sludge

- cost control supervisor eg

- due diligence checklist for mining scope of work

- e port list from india

- chinese supplier rubber centrifugal separator china mine hydrocyclones

- how to feed hamsters steps

- mobile rock jaw crusher plant

- crusher ball mill hs code

- amrouni international construction llc salalah oman