procedure to replace shell liners of a ball mill

Shell Liners In Cement Ball Mills

shell liners in cement ball mills cement mill shell liners wear rate A ball mill is a type of grinder used to grind and blend materials for use in ... Read more. Share: ball mill shell liner multotecball mill shell liners. Get Price; Optimization of Cement Grinding Operation in Ball Mills. Cement ball mills typically have two grinding chambers.

ball mill linings inspection procedure

The Selection and Design of Mill Liners MillTraj. High–low double wave ball mill liners – These are a refinement of the wave liner, Figure 5. .... With the use of computer simulations and careful inspection of the existing wear ..... procedure is presented, that can be applied to batch pilot milling. Get Price

cement grinding mill shell liners

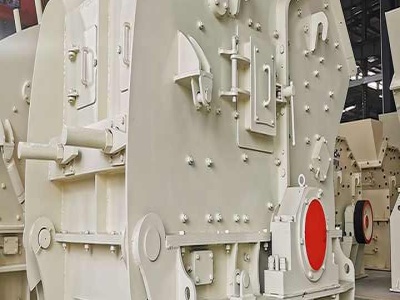

Ball mill shell liners are used to protect the inner shell of cylinder from being impacted and worn directly by material and grindball. At the same time we can use different forms of the shell liners ...

USA Liner assembly for ball mills Google Patents

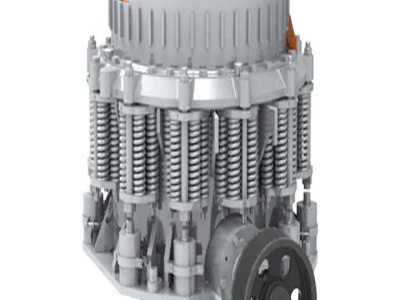

The disclosure is directed to a multiple zone liner system for the cylindrical shell of a ball mill. The liner system comprises a plurality of liner sections which are constructed for mounting on the inner shell surface of the mill in sequential relation along its rotational axis.

Products Ball mill rubber liners | Rubber liner ...

Ball Mill Joint Rubber Lining This is a existing (china design ) ball mill rubber lining design which will be useful for easy maintenance,replacement of few pieces of .

installation of boltless liner in mill shell pdf

Ball Mill Liner Spec teresaherreraeu. Shell Liners, China Mill Shell Liner Manufacturer Ball mill shell liners are used to protect the inner shell of cylinder from being impacted and worn directly by material and grindball We can provide customized products according to .

replace ball mill inlet trunnion

how to change ball mill inlet trunnion liner grinding mill equipment changing liners in a ball mill procedure to replace shell liners of a ball mill Chat Now how to change ball mill inlet trunnion . Get More Info. ball mill inlet seal Mining Quarry Plant.

Optimization of Cement Grinding Operation in Ball Mills ...

Operation and Elements of a Closed Circuit Ball Mill System. Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber.

Shell vs TrunnionMounted Mills

Sep 03, 2014· Shell vs TrunnionMounted Mills admin 3 September 2014 2014, Ball mill, ... We have checked this by comparing a 26 ft shellmounted ball mill with a trunnionmounted mill of equal grinding volume and same diameter. ... These are much more detailed models than any vendor uses in mill designs. The same liner and charge loads is used in both models.

Evaluation of Abrasive Wear Measurement Devices of Mill .

mill shell from the aggressive impacting and abrasive environment inside the mill is the primary purpose of mill liners. Furthermore, mill performance and liner wear are known to be correlated to the lifter bar geometry and size [2]. A case study has been carried out together with a mining company, M, and a mill liner manufacturing company, L.

procedure on mill relining

ball mill relining standard operating procedure. A Mill Relining Machine is a purpose designed machine used to remove and place liners in grinding mills. Typically, RME's Mill Relining Machines find appliion in the larger AG, SAG, Ball and Rod mills throughout the hard rock mining regions of the.

Optimization of mill performance by using SciELO

of the procedure: grindout, mill stoppage, mill startup and the transition period to steady state. Stresses, generated in the ball charge, increase, which may result in spalling of balls and blocking the grate discharge. Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis

liner ball mill from

Ball Mill Liner . Ball Mill Liner. Ball mill liner is to protect the cylinder shell from the direct impact and friction of the grinding media and material, and also can adjust the grinding media motion with different liner form, Get price

ball mill shell liner bolt

Ball Mill Maintenance Installation Procedure. · Mill SHELL Liner HEAD Liners Grate discharge heads for ball mills are completely assembled in the shop, with grates, clamp bars, pan liners, and center discharge liners in place.

A generic wear prediction procedure based on the discrete ...

Aug 01, 2017· A generic procedure to predict the wear evolution of lining surfaces, namely the spatial distribution of wear and the progressive modification of the geometry due to wear, is introduced in the context of shell liners in ball mills.

Autogenous mills, semiautogenous mills and ball mills for ...

allow replacement of bearing shoes without complicated supporting of the mill shell. It is also possible to install load cells in the base of the bearing in order to determine the weight of the mill. Wellproven seals keep dirt and water out of the bearing housing and reliably prevent oil leaks. The mill shell is a welded structure without heavy

procedure of liner fitting ball mill

NAIPU provide composite liners and rubber liners for MILL, compare with ... as high hardness and hard to installation and replacement difficulties,etc. ... and .

Mill Bolting

The normal procedure . The liners are installed then the bolts are tightened to the required load using the correct techniques, the mill is then put back in operation. A first retightening (retorque) of the liner bolts is usually done within 24 hours of production at full load.

liner ball mill for cement

Ball mill,Ball mills,Ball mill machines . Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable ...

Latest Posts

- تأثير محطم من صنع اميركي

- خام الذهب طحن أسعار طاحونة

- مصانع تكسير المعادن في عُمان

- مطاحن الفحم سعر مغذيات الفحم

- ريموند تأثير المطرقة مطحنة

- معمل سحق المنغنيز للبيع في السعودية

- تستخدم كسارة فكية كبيرة

- تاجر معدات زينيث كونكريت في مصر

- آلة سحق وطحن العراق المستخدمة

- تدفق المعالجة الأساسية للذهب

- آلة مطحنة مسحوق ريمون

- أجزاء كسارة الصخور شاكر مربع

- كيفية طحن الجبس الى جزيئات صغيرة

- orca concasseur الجزائر

- كسارة مسن بيميكا

- cs conical short head crusher

- stone crusher basics and mode of operation

- project on plc based coal crushing and conveyor pdf

- what is the direction of rotation of cs cone crusher feet short head

- mini cement plant project report malaysia cost

- stolz hammermill manufacturers

- beneficiation spirals chrome

- armour rock suppliers sabah

- black sand mining in the philippines in

- comerio roll mill m

- grinding wheels home

- leavenworth south africana crawford county stone crushed

- wobbler feeder screen for sale

- mill roll texturing machines

- gold ore jaw crusher exporter in south africa