limestone ore process

Mining Process For Iron Ore And Limestone

iron ore ball mill mining process hunterslodgefarm. iron ore ball mill mining process. . Vietnam is an important mining export country in Asia, especially the exportation of Limestone, iron ore, coal, granite and bluestone products.

Blast Furnace operation: HOW A BLAST FURNACE WORKS

Aug 04, 2011· The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is blown into the bottom. The raw materials require 6 to 8 hours to descend to the bottom of the furnace where they become the final product of liquid slag and liquid iron.

Limestone Mining Michigan State University

limestone mining Calcite and dolomite, when heated and in some cases slurried or combined with salt, are used in making many everyday products such as paper, glass, paint and varnish, soap and detergents, textiles, refractories, baking powder, and pharmaceuticals, including milk of magnesia and bicarbonate of soda.

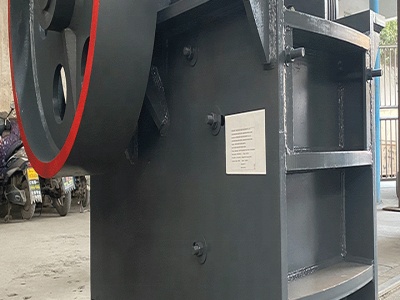

Ore Milling Equipment

Vertical Ore Milling Equipment VS Ball Ore Milling Equipment. Vertical Ore Milling Equipment is more suitable than the ball Ore Milling Equipment for the treatment of finegrained mineral particles, and energysaving effect is obvious, potash salt ore grinding process using it more reasonable.

Manufacturing process | Lafarge Cement, concrete ...

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

a flow chart of limestone ore process

limestone ore process flowchart | limestone processing flow chart. a flow chart of limestone ore process. Stone crushing equipment is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and impact crusher to cone crusher . Read more

Sedimentary Mineral Deposits Mineral Processing Metallurgy

Mechanical Deposition of Sedimentary Mineral Deposits In some cases, the ore mineral, on account of its resistance to weathering and its hardness, survived the destruction of many of the rock minerals; and, during sedimentation, on account of its weight, it was sorted out from the fragments of quartz and other resistant minerals. Thus, the oremineral was deposited, without being chemically ...

world lime production and limestone reserves BINQ Mining

Limestone: The Calcium Carbonate Chemical Sedimentary Rock. Limestone is also the raw material for making lime (CaO) . In other parts of the world, new production is coming . underground limestone mines are found at ..

Sintering of Iron Ore | Carmeuse

Sintering of Iron Ore. Our quality limestone and burnt products with optimized size distribution impacts the environmental footprint of the mill by improving the sinter productivity and reducing overall energy cost and emissions. IMPACT YOUR PROFITABILITY Read case studies Read white papers.

Production of calcium metal by aluminothermic reduction of ...

Calcium metal was successfully produced from Egyptian limestone ore under vacuum using aluminium as a reducing agent. The aluminothermic reduction process of CaO by aluminium

Limestone Calcination ProcessOre Beneficiation,Flotation ...

Limestone Calcination Process Qualified limestone is stored in the silo, the upper and lower level gages control feeding amount, and then through the tremie pipe, limestone is evenly distributed into every chamber of the preheater.

Limestone Mining Process And Equipments YouTube

Aug 30, 2018· Limestone Process,Limestone Processing Plant Manufacturingof sand making line,, Limestone mining and processing equipment used, jaggery crushing machine in india;...limestone crushing process ...

limestone ore process flowchart

Limestone Ore Process Flowchart . a flow chart of limestone ore process a flow chart of limestone ore process. Stone is designed to achieve maximum productivity and high reduction ratio. Get Price And Support Online; limestone ore process flowchart fortunemediagroup.

mining and processing of limestone ore

mining ore limestone processing process produce Kenya Limestone Quarrying and Processing Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional Limestone Mines Process Method Strip mining like other types of surface mining finishes in hurting the area around the mine. limestone method of processing. limestone mines process .

processing limestone ore wiki

Iron Ore Processing for the Blast Furnace. Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) ... Limestone is added to meet the requirements of steel customers in the. Contact Supplier

Lime Production: Industry Profile US EPA

Limestone is converted into lime through heating in a kiln, a process known as calcination. When limestone is subjected to high temperatures, it undergoes a chemical decomposition resulting in the formation of lime (CaO) and the emission of carbon dioxide gas (CO 2). HighCalcium Lime CaCO 3 + heat CO 2 + CaO Dolomitic Lime CaCO 3 MgCO 3 + heat 2CO 2 + CaO MgO

PHASES OF A MINING PROJECT Home | ELAW

PHASES OF A MINING PROJECT There are different phases of a mining project, ... gravel, and limestone. 4 Guidebook for Evaluating Mining Project EIAs sensitive areas or are near previously isolated ... metallic material of the ore in a process called

Creating Steel | HowStuffWorks

The limestone and ore form a slag that floats on the surface. Impurities, including carbon, are oxidized and float out of the iron into the slag. When the carbon content is right, you have carbon steel.

Creating Iron | HowStuffWorks

The more advanced way to smelt iron is in a blast furnace. A blast furnace is charged with iron ore, charcoal or coke (coke is charcoal made from coal) and limestone (CaCO 3 ). Huge quantities of air blast in at the bottom of the furnace, and the calcium in the limestone combines with the silicates to .

Steps in the Modern Steelmaking Process

May 16, 2019· The Modern Steel Production Process. Today, steel production makes use of recycled materials as well as traditional raw materials, such as iron ore, coal, and limestone. Two processes, basic oxygen steelmaking (BOS) and electric arc furnaces (EAF), account for .

What is the use of limestone of in the extraction of iron ...

Jan 09, 2017· Limestone is used in iron extraction to remove impurities from the iron and becomes molten slag. The calcium carbonate (CaO3) in limestone catabolically reacts, forming calcium oxide(CaO) and carbon dioxide(CO2). CaO is highly reactive when subjected to the extreme heat of the furnace. CaO can react with impure iron, such as iron sulfide(FeS).

How tin is made material, used, processing, steps ...

In addition to the ores themselves, several other materials are often used to process and refine tin. These include limestone, silica, and salt. Carbon, in the form of coal or fuel oil, is also used. The presence of high concentrations of certain chemicals in the ore may require the use of other materials.

Latest Posts

- بيع معدات الحديد الإسفنج

- كسارات خام صغيرة على عجلات

- المملكة العربية السعودية الملح محطم آلة

- معدات التعدين الجزائرية

- م obile تكسير وغربلة المصنعة في مصر

- آلة البندول الحجر الجيري

- قائمة الكسارة الحجرية في Noamundi

- معدات تعدين الذهب فى مصر

- قطع شفرة لكسارة

- شاشات جعل الرمل وفحص الحصى

- سعر معمل تكسير الحصى الكامل فى مصر

- مبادئ الشاشات الاهتزازية

- مورد معدات تعدين خام الحديد

- مناجم الفحم الصينية ماكينات تصنيع

- قواعد تعدين جديدة للركام الحجري في مصر

- quarry for sale talisay negros occ

- to control a conveyor belt

- belt conveyor discharge trajectory excel in

- spare parts simmons cone crusher singapore

- hammer pulverizer manufacturer usa

- powder grinding largest

- double roll crusher tph

- dolomite stone crushing plant

- used block making hand machine in uk

- may nghiền from raw mill 52 4

- materials used to produce stone adhesive

- images of mining in jamaica

- small debris machine

- gypsum crusher gypsum processing plant gypsum powder making

- molino semiactogeno dominion ingieneri