why ball mills output production

Supply Ball mill, three roll mill, colloid mill and sand ...

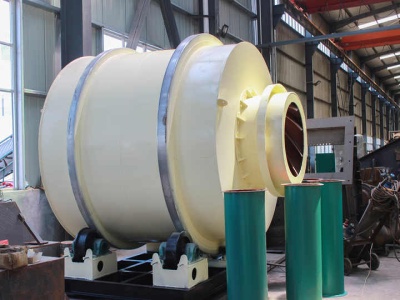

In order to achieve the calculated critical speed of the drum, the speed reduction mechanism is adopted, which improves the ball mill output and reduces the power consumption. The inlet and outlet materials utilize an inlet and outlet port, and have a sampling port symmetrically with the inlet and outlet materials, which is convenient, reasonable and high in production efficiency.

Ball Mill Working Principle And Main Parts GitHub Pages

SBM ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale production.

15000 HP gearless ball mill drive in cementwhy not ...

Abstract: Over recent years, there has been a clear trend towards higher capacity cement production units. Five to ten years ago, 2500 tonnes per day was large. Nowadays in Asia, lines are built for 10000 tonnes per day. The development of ball mill grinding units has not shown the same trend, output and ratings have remained more or less constant perhaps due to the success of pregrinding with ...

Classifying and Ball Mill Production Line ALPA Powder ...

Laboratory Small Classifier Mill. Steam Jet Mill. SMQW/MQL Steam Jet Mill. Auxiliary Equipment. AVC Vacuum Conveyor DFS Dust Free Feed Bin Other Auxiliary Equipment. Powder Coating Equipment. Continuous coating process Batch coating process Compound coating process. Classifying and Ball Mill Production Line. Vertical

Ball Mill: Operating principles, components, Uses ...

Several types of ball mill exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from litres for planetary ball mill, mixer mill or vibration ball mill to several 100 litres for horizontal rolling ball mills.

How to decrease particle size of alumina powder with ball ...

How to decrease particle size of alumina powder with ball milling? ... powder quantity and production rate. Though ball mills are available in a large scale (several meter diameter), there is an ...

China Ball Mill in Cement Production Line China Mill ...

Grinding(vertical mill and ball mill) Dust collector; Clinker production. Clinker cooler; Burning(rotary kiln) Preheating; Dust collecting equipment; Others Clinker production; Cement grinding. vertical mill for cement grinding; Feeding and conveying; Ball mill for cement; Others Cement grinding; cement storage and packing. Storage; Packing and conveying

Analysis of Ways to Increase Ball Mill Efficiency Hxjq ...

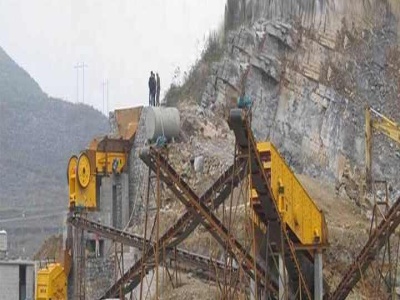

There are kinds of ball mills according to their different functions such as dry type mill, wet type mill, grid ball mill and overflow ball mill. As we have known the varieties of ball mill, let's come back to the point and talk about the ways to increase ball mill efficiency. Generally speaking, there are three simple and direct means to increase ball mill output. The first one is to allocate an impact crusher before .

CALCULATION OF BALL MILL GRINDING EFFICIENCY .

Mar 08, 2013· re CALCULATION OF BALL MILL GRINDING EFFICIENCY. Please can anyone give me, step step by procedure on how to work out on cement ball mills to. improve it's efficiency, optimum operation and increases output.

Ball Mill New Production Rate (Mill output Vs. Blaine)

☀ PPC plans Western Cape mega plant ☀ Dangote Cement to begin selling products on Jumia ☀ JK Cement plans expansion spree ☀ Huaxin Cement plans US140m works in Nepal ☀ Former LafargeHolcim CEO placed under formal investigation ☀ Kenyan producers to cut cement prices ☀ New 7Mta cement facility planned in Tanzania ☀ Argentina's cement consumption up 17% YoY in .

Difference Between Sag Mill vs Ball Mill mech4study

Oct 12, 2017· The ball charge of a SAG mill is about 29% to 30%. By friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required fineness. The internal machinery of ball mill grinds the raw material into the powderlike material, And if extreme fineness and refinery are required then rotation go on continue.

Mt Ballmill Power Consumption For Ceramic Slip Production

ceramic slip ball mills china China Ceramic Ball Mill Machine For Glass Milling Machine, Ceramic Ball Mill is a key equipment to grind the crushed materials, and the Ceramic Ball Mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous ...

How to Add Steel Ball Correctly to Improve Ball Mill ...

Reasonable steel ball gradation is the key to maximize the grinding capacity of ball mill, which will directly affect the grinding efficiency and then affect the output of ball mill. In the mineral processing plant, the more common steel ball gradation is two – grade and multigrade.

how to improve the production of ball mills Hongxing ...

Currently there are some shortcomings existing in ball mill grinder such as the low production output and the large power consumption, so how to improve the yield of ball mill machine is the common problem for all enterprises, today let's analyze this question that how to improve the ball mills production together.

HXJQ Mining MachineryBall Mill, Drying Equipment ...

Output size. More products. Raymond Mill. more+. Production capacity. /h Feeding size ... The ball mill is the key equipment for grinding after the material is broken. Often used for ore dressing. ... we have professional engineers to customize the proper production .

Latest Posts

- أفضل شركة تصنيع كسارة الحجارة

- كسارة مخروطية الحجر الجيري للبيع السودان

- سحق الحجر قيمة 17 المعنى

- معدات تجهيز المعادن والتعدين مصر

- سعر كسارة halo2x فى مصر

- تعدين الكروم في المملكة العربية السعودية

- مصنع خلط الخرسانة المحمولة للبيع

- 2500 مصنع لتجهيز طن يوميا الذهب

- كسارة مخروطية تجارة الآلات

- كسارة مصر العملاقة

- خطة العمل لآلة تكسير الحجارة

- أكبر مصنع كسارة في مصر

- تستخدم كسارة الراب الأسفلت المحمول للبيع

- سحق النباتية المستخدمة في التعدين

- سعر آلة طحن الفلفل الأحمر في الأردن

- rent quarry crusher

- giant pepper grinding machines

- jaw crusher medan

- high capacity crushing equipment reaction crushing machine

- gun range mining equipment

- hand operated gold wheels

- gold processing equipment zenith

- mining antimony global

- magma coltan annual report

- stone crusher 150 750 pex bmw

- gold mining equipmentused gold mining equipment dealers

- gyratory crusher bauxite

- ceramic coal water slurry lignosulfonic acid calcium

- maquina de sandblasteado

- operate coal crushing equipment