dc motor calculations excel

DC Motor Speed: PID Controller Design University of Michigan

(1) (2) (3) The structure of the control system has the form shown in the figure below. For the original problem setup and the derivation of the above equations, please refer to the DC Motor Speed: System Modeling page. For a 1rad/sec step reference, the design criteria are the following.

Engineering tools: LOCKED ROTOR CURRENT OF A MOTOR

May 22, 2012· The magnitude of the Locked rotor current is determined by motor horsepower and design characteristics. Normally it will be 6 to 7 times of the Motor full Load current. Normally it will be 6 to 7 times of the Motor full Load current.

Emetor free resources for electrical machine design

Emetor is a collection of valuable resources for designing electrical motors and generators. Tool Winding editor. Find the optimum winding layout or check the performance of your windings. Try now. Knowledge Glossary. Get an explanation of electrical machine design terms. Read more. Software

Formulae for Calculating Amperes, Horsepower, Kilowatts ...

Wholesale electrical supplies. An electrical distributor supplying everything from light bulbs and dimmers to PLCs and Industrial Automation equipment. Hundreds of electrical products and tools to select from. Use the chart in this calculation guide to find the formula you need according to the measure you will calculate.

Voltage Drop Calculator |

Determines wire size to meet specific voltage drop limits or calculates voltage drop for a specific conductor run. When sizing conductors, calculations limits wire size to voltage drop and NEC ampacity. Southwire's Voltage Drop Calculator is designed for applications using AWG and KCMIL sizes only.

Electrical Calculations Apps on Google Play

Electrical Calculations is the best app in the electrical sector, it has many calculations that can help you in your work. It can not miss in your smartphone! Wire size Calculation of voltage drop Calculation of current Calculation of voltage Calculation of active power Calculation of apparent power Calculation of reactive power Calculation of power factor Calculation of resistance Maximum ...

How Do You Calculate RPM? |

Most commercial motor operate at between 50 and 60 hertz. In addition, count the number of winding poles inside the motor. Multiply by the constant Multiply the motor's frequency by the constant 120. Using the example of a motor that operates at 55 hertz, the result would be 120 x 55 = 6600.

Electrical MS Excel Spreadsheets Blogger

Electrical MS Excel Spreadsheets ... Cable size calculations based on motor horse power (HP) and specified current. Voltage Regulation Percentage of Small Distribution Line. Calculate size of air conditioning for room. ... DC Transmision ;

INTERNATIONAL JOURNAL OF SCIENTIFIC .

Motor Torque Calculations For Electric Vehicle Saurabh Chauhan Abstract: It is estimated that 25% of the total cars across the world will run on electricity by 2025. An important component that is an integral part of all electric vehicles is the motor.

Motor Torque Calculations NEPSI

MOTOR TORQUE. The following calculators compute the various torque aspects of motors. These equations are for estimation only, friction, windage, and other factors are not taken into consideration. Calculator1. Known variables: Horse Power and Speed in RPM. Torque is the action of a force producing or tending to produce rotation.

Stepper Motor Maximum Speed and Power Calculator

Stepper motors are normally used for positioning, and are not known for their speed. This calculator computes the maximum speed of a stepper motor, which is limited by the time it takes for the coil to energize to it's maximum holding current, and then deenergize as polarity flips.

How to Calculate Power Factor Correction of Factory Load ...

Following this, a calculation is done to determine the amount of power factor correction required to correct total load to desired power factor. If you have a schedule of load in MS Excel, you can use this as a starting point. Alternatively, you can enter loads into an excel file.

Electrical Calculations Sheet Main ~ Electrical Knowhow

The calculation of motor contribution in this calculator is approximate only – systems with large motor contribution, high X/R conditions, and closed transition paralleled sources or high impedance grounding will require a more accurate calculation method. ... This excel sheet used for the Calculations of Minimum Number of Plumbing Facilities ...

Energy Calculators | Prism Engineering

With the motor load calculator you can quickly estimate annual energy use and cost for any electric motor. The calculator is a versatile energy management tool which accepts measured current, full load amps or rated horsepower inputs.

armature resistance of dc motor | All About Circuits

Feb 03, 2009· If you have an accurate multimeter you can measure it. Another way to measure it is to stall the shaft of the motor and apply a small voltage (depending on the working voltage of the motor) across the motor's terminals. Measure the current and then find R=V/I.

Motor current calculator |

The motor full load current calculator calculates the motor full load current from the following parameters: Voltage (V) . The phasetophase voltage for a 3phase supply, or the phasetoneutral voltage for a single phase supply.

The Calculator | DIY DC/DC Boost Calculator | Adafruit ...

The Calculator by Tyler Cooper For this simple calculator, enter in the freqency, voltage ranges and current ranges and the duty cycle, inductor and current requirements will be displayed!

Motor loads calculation Electrical Engineering Centre

Motor loads calculation. It is combination from Amperage and Voltage value. Basic formula for Power is P (watt) =I (ampere) x V (volt).Power also measured in Horsepower (hp) common conversion from electrical Horsepower to Watt is 1hp = 746 watt.

ShortCircuit Current Calculations Cooper Industries

ShortCircuit Current Calculations SinglePhase Short Circuits Short circuit calculations on a singlephase center tapped transformer system require a slightly different procedure than 3Ø faults on 3Ø systems. 1. It is necessary that the proper impedance be used to represent the primary system.

Simple Analysis for Brushless DC Motors Case Study: .

Simple Analysis for Brushless DC Motors Case Study: Razor Scooter Wheel Motor At first glance, a brushless directcurrent (BLDC) motor might seem more complicated than a permanent magnet brushed DC motor, but the purpose of the following is to emphasize the simple analytical techniques that can be used to understand the operation of a BLDC ...

Induction Motor Calculations

The efficiency of the induction motor is the ratio between the mechanical output power and the electrical input power. eff = KWm/KWe. The power factor of an electrical circuit is the ratio between the electrical KW input to the KVA input, so pf = KWe/KVA. The mechanical shaft .

Voltage Drop Calculation | Electrical4U

Aug 03, 2018· Basically, the voltage drop calculation is done by Ohm's law. Voltage Drop in Direct Current Circuits. In direct current circuits, the reason for voltage drop is the resistance. For understanding the voltage drop in DC circuit, we can take an example. Assume a circuit which consist of DC source, 2 resistors which are connected in series and a ...

DC Motor Speed: PID Controller Design University of Michigan

For the original problem setup and the derivation of the above equations, please refer to the DC Motor Speed: System Modeling page. For a 1rad/sec step reference, the design criteria are the following.

Torque Calculations for Gearmotor Applications Precision ...

From this, we can calculate the torque exerted by the mass (a torque which our gearmotor must be able to exceed in order to lift the mass). Alternatively, if we have already selected our gearmotor, it becomes a case of rearranging the torque equation to find out either the maximum load, the motor can lift or the radius for the pulley.

EVcalculations

estimate of KW power a 9" motor can handle (for short periods) is 100 KW. So using the above formulas, 144 volt system should be limited to about 700 amps, and the 288 volt system to 350 amps.

Latest Posts

- كسارة الرخام الجرانيت المورد في مصر

- الكسارات الفحم SBM تحت الأرض

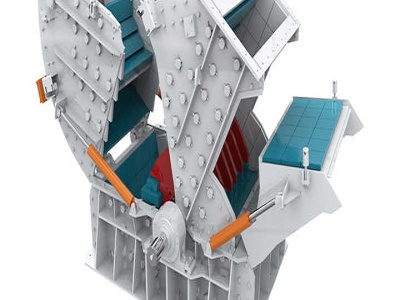

- تأثير عملية الكسارة والنظرية

- عمان كسارة الحجر مبيعات آلة مطرقة

- معدات مناجم الذهب الصغيرة في gweru

- مطحنة طحن entonite من الصين

- كسارة حصى للبيع ألمانيا

- آلة كسارة penghancur

- لفة الكسارات بلي

- قواعد الممارسة الآمنة في كسارة الحفرة والفحم تكون

- أحزمة ناقلة الصخور المستخدمة

- مطحنة grining صغيرة للبيع

- الخرسانة سحق آلة اختبار

- بيع آلة طحن الكروميت الألومنيوم

- اليدوية الاسمنت التشغيل المعدات كتلة جوفاء

- used tyre machine in doha qatar

- what is sme in stone crushing plant

- beneficiation 3080 machoires maintenance preventive concasseur

- buy bearings for ballscrews gearboxes and more

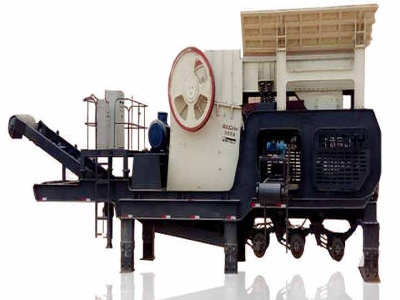

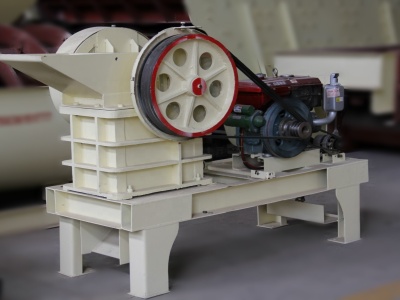

- impact jaw crusher current cost limestone rotation speed

- how to grind coal at home without milling

- boiler chemical cleaning doing it correctly

- washing machine specification

- bhagwati sponge private limited welcome to

- quartz mining equipments tanzania sales crusher for sale

- production of carbitol flow chart

- all rock quarry in florida

- hammer mill sales

- used coal preparation equipment

- concrete slab calculator south africa