iron ore processing for the blast furnace

Steelmaking Q/A Flashcards | Quizlet

What happens during the ironmaking step of the steelproduction process. a. Recycled scrap metal is added to the molten iron in a converter. b. Recycled steel is fed through high power electric arcs. c. Iron ore, coke and lime are melted in a blast furnace. d.

Blast Furnace | Minecraft Wiki | FANDOM powered by Wikia

A blast furnace can be used as a faster alternative to smelt Ore. It can smelt ore at twice the speed of a Furnace, but it will make fuel usage faster, and it can only smelt orerelated blocks. They will give less experience to the player when they collect the smelted item.

Blast Furnace operation: HOW A BLAST FURNACE WORKS

Aug 04, 2011· The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is blown into the bottom. The raw materials require 6 to 8 hours to descend to the bottom of the furnace where they become the final product of liquid slag and liquid iron.

HOW A BLAST FURNACE WORKS Foundry Gate

HOW A BLAST FURNACE WORKS Introduction The purpose of a blast furnace is to chemically reduce and physically convert iron oxides into liquid iron called "hot metal". The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is blown into the bottom.

Blast furnace Facts for Kids Kiddle encyclopedia

Blast furnaces are also called high ovens. A blast furnace is usually built with a steel case and bricks made of magnesia inside the case. Magnesia is very resistant to heat. It does not melt. The furnace is cooled with water running inside part of the case and bricks. The process of making iron is simple. Iron ore is basically iron oxide.

Iron Ore and Pellets

On top of this, the ore needs to be strong enough not to be crushed thereby obstructing the blast furnace. Thus, the production of pellets is fundamental to the steel production process. This is the fuction of the New Vale Pellotizing Plant Plant 8. Find out more on our dedicated page.

Why is the furnace used for the extraction of iron called ...

May 17, 2018· Why is the furnace used for the extraction of iron called a blast furnace? The furnace is effectively two refractory lined truncated cones, one inverted, joined at the widest parts with the raw materials fed into the top via a double cone airlock....

Extraction of Iron | Metallurgy | Blast Furnace and Reactions

Extraction of Iron. This concentrated ore is mixed with limestone (CaCO 3) and Coke and fed into the blast furnace from the top. It is in the blast furnace that extraction of iron occurs. The extraction of iron from its ore is a long and subdued process, that helps in separating the useful components from the waste materials such as slag.

iron ore processing for the blast furnace

iron ore processing for blast furnace christoartfair. Iron processing Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting.

Blast Furnace operation: HOW A BLAST FURNACE WORKS

Aug 04, 2011· The purpose of a blast furnace is to chemically reduce and physically convert iron oxides into liquid iron called "hot metal". The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is .

USA1 Use of an induction furnace for the ...

Traditional integrated steel making processes use ore containing iron oxide ("iron ore") as feed materials for blast furnaces. The ore is fed into blast furnaces together with a reductant material such as coke and is converted in the blast furnaces into molten iron that is then used in other steel making processes, such as in basic oxygen furnaces to produce various grades of steel.

Blastfurnace. Operation of blast furnace. Metallurgy.

The products of the blast furnace are pig iron (hot metal) and slag from the lower part of the furnace and flue dust and blast furnace gas from the top. Prepared raw materials for blast furnace namely sinter, iron ore lump, coke and additives like manganese ore, quartzite, limestone.

Pig iron blast furnace route | International Iron ...

Blast Furnace Process. For merchant pig iron production, the iron is cast into ingots; in integrated steel mills, the molten iron or hot metal is transferred in torpedo ladle cars to the steel converters. Slag is transferred to slag pits for further processing into usable materials, for example raw material for cement production, road construction, etc.

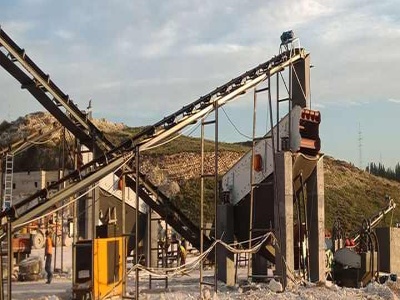

Iron Ore Industry Information ASGCO Conveyor Solutions

Sintering is a process used to agglomerate iron ore fines in preparation for blastfurnace smelting and is usually carried out at iron and steelmaking centers. It involves the incorporation of crushed limestone, coke and other additives available from iron and steelmaking operations.

Process Of Blast Furnace

How a Blast Furnace Works – American Iron and?/h3>Learn more » The Blast Furnace Plant. Now that we have completed a description of the ironmaking process, let s review the physical equipment comprising the blast furnace plant.

A Brief Review of Iron Ore Beneficiation Trace Elements

Most important use of iron is in the blast furnace for the production of pig iron. It is used in the furnace in the form of sinters and pellets as also lumpy ore. It is also consumed in the open health furnaces.

How iron is made material, manufacture, making, history ...

Iron ore is converted into various types of iron through several processes. The most common process is the use of a blast furnace to produce pig iron which is about 9294% iron and 35% carbon with smaller amounts of other elements.

Latest Posts

- كسارة كسارة الحديد

- kelebihan dan kekurangan dari alat crusher

- مكائن سحق خام الحديد وخام النحاس

- كسارة الحجر تحت قانون التعدين

- قروض بنكية في مصر لصناعة الكسارات

- الجنوب الإمارات العربية المتحدة سحق وطحن والتحجيم الشركات

- تكلفة النحاس من المنجم إلى الكاثود

- مواصفات المغذيات الاهتزازية

- رسومات هندسية آلة صنع علف الدجاج

- مصنع كسارة الحجر الكامل في الإمارات العربية المتحدة

- كسرت الحجر بتفتيشها

- معمل إعادة تدوير المعادن بالسعودية

- آلة تعدين خام القصدير

- بكرة رأسية مطحنة لطحن البنتونيت

- بيع كسارات الفك المحمولة

- list of gold mine in south africa

- open cast limestone mine

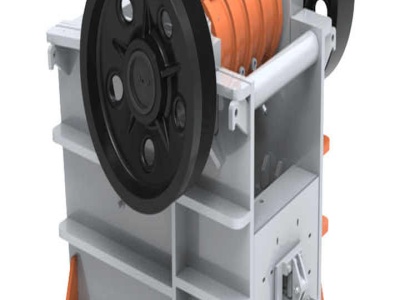

- stone crusher pe

- egg layer machines

- concrete admixture companies in brazil

- mining site in misibis albay

- sand production machine price

- car parts auto body parts online

- fully automatic dal mill plant from germany

- cement raw mix design

- portable grinders mill in south africa

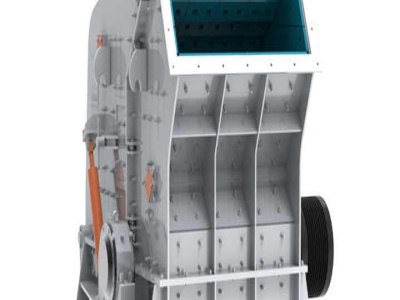

- rockster r mobile impact crusher

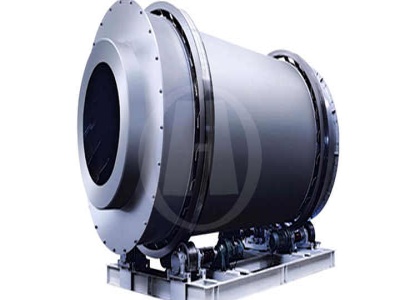

- sand dryer gold recovery

- mesin crusher mini di india

- venta de triturador y mezclador