coal wash plant waste

Reducing the environmental impact of coalwashing practice ...

All Australian coal for export is washed — that is, the lowgrade highash material is separated out and disposed of at the washery site. The coarse rejects are generally placed in embankments and the tailings are pumped into settling ponds. These methods of waste .

Why Trump just killed a rule restricting coal companies ...

Feb 16, 2017· Why Trump just killed a rule restricting coal companies from dumping waste in streams. In early February, the House and Senate voted to repeal the socalled "stream protection rule" — using a regulationkilling tool known as the Congressional Review Act. On Thursday, President Trump signed the bill, which means the stream protection rule is now dead. Coal companies will have a freer hand .

SOLID WASTE FROM THE OPERATION AND .

The two largest forms of solid waste from coalfired generation are coal ash (from the combustion of coal), and "scrubber" slurry (from environmental controls at the plant). Collectively, these two wastes are called coal combustion residues, or CCRs. CCRs are the second most abundant waste material in the United States, after waste.

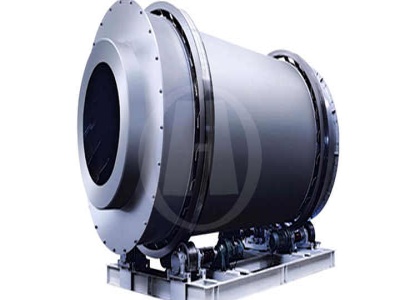

Coal washing process, methods, equipments, coal beneficiation

Coal washing is a processing technology that adopts physical, chemical or microbiological methods to separate coal and impurities by their differences in physical and chemical properties. The coal beneficiation methods can be divided into physical coal beneficiation, physicalchemical coal beneficiation, chemical coal beneficiation and microbiological coal beneficiation.

What is clean coal technology? | HowStuffWorks

A coal derivative, a solidified carbon called coke, melts iron ore and reduces it to create steel. But most coal 92 percent of the supply goes into power production [source: Energy Information Administration]. Electric companies and businesses with power plants burn coal to make the steam that turns turbines and generates electricity.

coal wash plant refuse

coal wash plant refuse Ontwikkeling op Maat. Coal Wash Plant Refuse. Coal preparation plant Wikipedia. A coal preparation plant (CPP also known as a coal handling and preparation plant (CHPP), coal . Coal slurry impoundment SourceWatch. Jun 26, 2017 After the dam is built, the void behind it is typically filled with millions of gallons of waste ...

Coal Slurry and Coal Ash | SouthWings

Coal sludge impoundments, or "ponds," can store billions of gallons of liquid coal waste known as sludge or slurry. Coal companies say the sludge contains mostly water, rocks and mud. But it also contains carcinogenic chemicals used to process coal and toxic heavy metals that are present in coal, including arsenic, mercury, chromium, cadmium, selenium, and others.

Utah coalcleaning plant leaves behind trail of waste and ...

But BRC's Wellington Dry Coal Cleaning Plant proved a failure, and now its operators have abandoned the 30acre facility, still contaminated with coal waste, according to documents from the Utah ...

COAL WASHING PLANT – HCI

Aug 13, 2010· The 300t/h coal washing plant will beneficiate raw coal to a level suitable for sale to Eskom It will operate on a continuous basis for six working days a week, or 6 000 operational hours a year. Later, the plant will be upgraded to treat 700 i/h head feed. Source: Mining Weekly

The Dirty Secrets of Coal Cleaning: Pollution and ...

Coal preparation plants utilize large quantities of water and chemicals to separate rocks and dirt and the refuse from mined coal and break the coal into marketable sizes. While each plants processes and chemicals may differ slightly,3 preparation typically involves breaking, screening, and washing.

Reuse Options for Coal Fired Power Plant Bottom Ash and ...

Reuse Options for Coal Fired Power Plant Bottom Ash and Fly Ash ... a Solid Waste from the Decommissioning of CoalFired Power Plants ... by basic leaching and a water wash .

List of Residual Waste Beneficial Use General Permits

Beneficial use of a mixture of dry flue gas desulfurization waste (FGD waste) and coal ash from coalfired power plants for reclamation of coal mine sites. WMGR126 (PDF) Processing of silver bearing films and sludges ("waste") prior to further silver reclamation and plastic recycling through granulation, film washing using sodium hydroxide or ...

coal wash plant price in the usa

Environmental impacts of coal SourceWatch. Climate impacts of coal plants Coalfired power plants are responsible for onethird ... from coalfired power plants are the largest source of mercury in the United States, ... effects from the mining, processing, burning, and waste storage of coal. ... mining; 9 Coal transport; 10 Cost of environmental damages from coal plants.

![coal washing plant[mining plant]](/2czemp0/1347.jpg)

![coal washing plant[mining plant]](/2czemp0/1345.jpg)

coal washing plant[mining plant]

Coal preparation plant Wikipedia, the free encyclopedia. A CPP may also be called a coal handling and preparation plant (CHPP), prep plant, tipple, or wash more of this waste material that can be removed from coal.

environmental science semester 2 review 1 Flashcards | Quizlet

the material, mostly smoke, ash, and particulate dust that comes out of a smokestack at a coalburning power plant lignite a geologically young form of coal, has a .

Coal Cleaning US EPA

Coal Cleaning Process Description12,9 Coal cleaning is a process by which impurities such as sulfur, ash, and rock are removed from coal to upgrade its value. Coal cleaning processes are categorized as either physical cleaning or chemical cleaning. Physical coal cleaning processes, the mechanical separation of coal from its

Coal fired power plant Energy Education

Once unloaded, the coal is then pulverized into a fine powder by a large grinder. This ensures nearly complete burning of the coal in order to maximize the heat given off and to minimize pollutants. The pulverized coal is then input to a boiler, where combustion .

Wastetoenergy plant Wikipedia

Wastetoenergy plants produce fly ash and bottom ash just as is the case when coal is combusted. The total amount of ash produced by wastetoenergy plants ranges from 15% to 25% by weight of the original quantity of waste, and the fly ash amounts to about 10% to 20% of the total ash.

Latest Posts

- تكلفة مشروع مصنع الاسمنت المصغر 50 طن في اليوم في مصر

- آلة تكسير الحجر اللاتريت

- سكيما ديزاين كسارة

- كسارة الحجر snd

- تأثير الطاحن من أحدث مطحنة كسارة الفحم

- تفاصيل contunt شركة كسارة zenith في الصين

- معدات التعدين خام الذهب في سنغافورة

- كسارات السودان للبيع في السويد

- خطة الجرانيت حجر محطم التجارية

- دائرة الأسلاك لآلة الطحن

- تستخدم كسارة الطوب للبيع المملكة العربية السعودية

- معدات تعدين الذهب صغيرة للبيع سعر

- معدات آلات التعدين القديمة

- منتجات كسارات الكروم

- فرق محوري و محطممطحنة لفة كسارة 325 شبكة

- marble granite crushing machine germany

- small scale miners physical processing plant of gold in the philippines

- punjab crusher house

- impect crusher sbm

- australia used construction equipment

- crusher fines in albuquerque

- conical ball continuous

- hardinge conical making

- belt conveyors feet

- indonesiacrushers s cone crusher

- zinc processing methods

- used barite grinding plant high

- rhodax crusher parts

- china mining equipmentw cone crusher

- crusher parts prices jul