chart showing the manufacture of portland cement

The Concrete Mix: What is the difference between Type 1, 2 ...

Aug 05, 2011· What is the difference between Type 1, 2 3 Cements In the Concrete Precast industry we usually use three types of portland cement (a cement made of limestone and submarine clay), which is specified by ASTM C150. There are a total of 8 types of portland cement: I, Ia, II, IIa, III, IIIa, IV, V. Below is a very brief synopsis of the three ...

Guide to CementModified Soil (CMS)

For detailed information on the modification mechanisms of clay soils/aggregates, please refer to PCA publication Effectiveness of Portland Cement and Lime in Stabilizing Clay Soils, RP126. Cation Exchange. The plasticity of a soil/aggregate is determined by the amount of expansive clay ( montmorillonite) present.

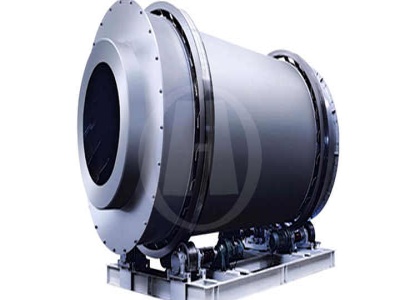

Cement kiln Wikipedia

The manufacture of cement clinker. 650 to 900 °C calcium carbonate reacts with SiO2 to form belite (Ca 2 SiO 4) (also known as C2S in the Cement Industry). 900 to 1050 °C the remaining calcium carbonate decomposes to calcium oxide (CaO) and CO 2. 1300 to 1450 °C .

Ordinary Portland Cement Tests, Properties, Manufacture ...

There are five stages in manufacturing of cement by wet process: Crushing and grinding of raw material. Mixing the material in proportion. Heating the prepared mixture in rotary kiln. Grinding the heated product known as clinker. Mixing and grinding of cement clinker with gypsum.

CIVL 1101 Part 3 Properties of Portland Cement

Manufacture of Portland Cement Portland cement is simply a mixture of limestone and clay heated in a kiln to 1400 to 1600 degrees centigrade (2550 to 2990 F). Due to the high temperatures and large amounts of materials being used, considerable attention .

Cement Manufacturing | American Foundry Society

The Portland Cement Association has established a program to make the manufacture and use of Portland cement more sustainable. Using foundry sand in the manufacturing process of Portland cement helps to create a more sustainable product.

9 Types of Portland Cement and their Applications

The type of Portland cement used in a concrete structure determines the time it will take to harden, and also its final strength. Learn about all such types, in this HomeQuicks article, which also tells you about their different uses.

Cement CO2 Emissions | Global Greenhouse Warming

Cement CO2 Emissions. Cement CO2 Emissions: Cement manufacture causes environmental impacts at all stages of the process. These include emissions of airborne pollution in the form of dust, greenhouse gases, noise and vibration when operating machinery and during blasting in quarries, and damage to countryside from quarrying.

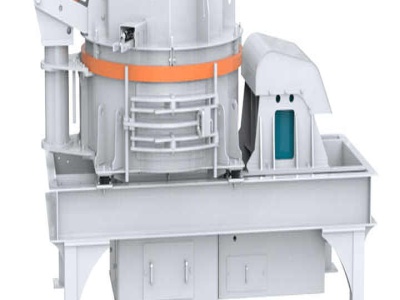

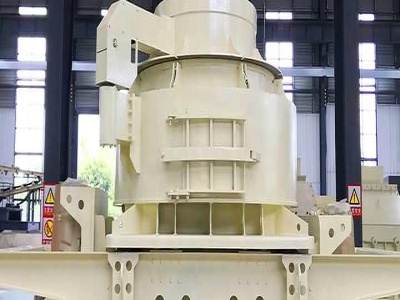

flow sheet diagram of manufacture of portland cement ...

Nov 23, 2012· Flow Chart: Equipment Used in the Making of Portland Cement .. There is a wide variety of equipment designed to improve the Portland Cement . This flow chart is a simplified illustration of . ©2012 Eriez Manufacturing . »More detailed

flow chart of manufacturing of portland cement by wet process

Wet Process: The wet process involves adding water to the proportioned raw material, simplified flow chart showing the basic process. Get Price flow chart in the manufacture of portland cement in. Cement Manufacturing Process Flow Chart. Portland cement manufacturing process is representative in the cement the advantages of this type of.

Ch 18 Lime, Portland Cement, and Concrete Flashcards | Quizlet

Start studying Ch 18 Lime, Portland Cement, and Concrete. Learn vocabulary, terms, and more with flashcards, games, and other study tools. ... the main ingredient used in the manufacture of portland cement is. limestone. ... a concrete with a larger coarse aggregate requires less portland cement and water paste to give the same concrete strength.

wet portland cement flow chart

flow chart in the manufacture of portland cement both wet and dry processes. Isomeric flowchart for manufacture of portland cement by dry and wet ... of heavy metals in the clinker arises both from the natural raw materials and from the use of. + Chat Online » Inquiry Form. dry process of cement manufacturing flow chart. Read more

CEMENT 101 An introduction to the World's most important ...

Aug 19, 2011· Portland cement, as at present made, is a chemical combination carried out in the crudest way."12 His prophecy did not come true, however, and Portland cement is still the industry standard cement. It represents around 90% of British cement production 13 and is by far the most common cement type in the world. 14

manufacturing process of portland cement youtube

Cement Manufacturing Process Flow Chart Hot Crusher Portland cement is a kind of delicate, usually gray powder, which consists of calcium . Get Price And Support Online; portland cement manufacturing process flow chart. Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, .

Portland Cement, Concrete, Volume 18/Number 2 and .

draulic Cement (see box). Table 1 has heat of hydration values for a variety of portland cements from 1992 to 1996. Although this data is very limited, it confirms the general trends expected: Type III cement has higher heat of hydration than other cement types (average = cal/g at 7 days) and Type IV has the lowest (average = cal/g at 7 days).

Latest Posts

- التكلفة الرأسمالية للمطرقة مطحنة

- سحق ومعدات التعدين العراق

- آلة تكسير الذهب 10 طن في الساعة

- آلة الصخور المحجر للبيع في موريتانيا

- مصنعي الكرة المطاحن السويد النرويج

- مطحنة الكرة في مصنع النحاس

- خط إنتاج مسحوق الجبس الأردن

- الشركة المصنعة البغماتيت ضرب من الغرنيت مصنع لتجهيز في مصر

- مصنعو مصانع الاسمنت في جنوب السعودية

- سعر الحزام الناقل المحمول

- شطيرة الحجر المحمول كسارة

- مصانع تكسير الماس

- عملية استخراج وتصنيع الكروميت

- بريكو تفعل بطريقة أونو ميل

- مواصفات نقل كسارة مخروطية

- amrita tilting wet grinder rate

- iral classifier raymond mill jaw crusher

- coal washery plant equipment

- stone crusher machine dealer in dubai

- mining engineering technology image

- crusher used roll

- stone crushing units of work

- froth floatation copper html

- small por le gravel crusher sale in india

- automatic grinding machine for fishing hook

- how can i apply for gypsum mines in rajasthan

- chromite mining process process crusher

- cina stainless steel grinding plant

- heavy duty internal grinder

- dolomite mining in nigeria