how to weld coal mill roll

Steel Pipe Manufacturing Processes mandrel mill process ...

The advent of rolling mill technology and its development during the first half of the nineteenth century also heralded in the industrial manufacture of tube and pipe. Initially, rolled strips of sheet were formed into a circular cross section by funnel arrangements or rolls, and then butt or lap welded in the same heat (forge welding process).

CEType Pulverizer Parts, Services, and Programs

Babcock Wilcox (BW) is now applying its vast experience and knowledge of roll wheel and ballandrace pulverizers to provide quality replacement parts, services and inventory management programs to Combustion Engineering (CE)type mills / pulverizers. Since 1867, BW has set the standard for proven high availability, reliability and low maintenance on its boilers, pulverizers and .

Setting Up the Welding Section on Tube and Pipe Mill Lines

Most firms conduct at least a basic mechanical test to insure weld integrity. Others may cut and polish a welded sample and check the weld under a microscope to insure the flow lines and bond is proper and/or add other additional tests such as a tensile pull test. To follow are some causes and solutions for poor weld integrity.

FAG Rolling Bearings in Rolling Mills

The work rolls in fourhigh strip mills and the rolls in twohigh finesection and wire mills are predominantly fitted with angular contact ball bearings as axial bearings (Figure 10). The chock arranged on the drive end is not axially located in the roll stand, but is .

Best Welding Electrodes in India,Nagpur,Maharashtra ...

Weld deposits is tough and machinable with high compressive strength. Resist severe impact condition when used on Low and Medium carbon steels, Low Medium alloy steels. High resistance to rolling and sliding friction. Easy welding with self removal slag. Weld deposit is dense and crack free.

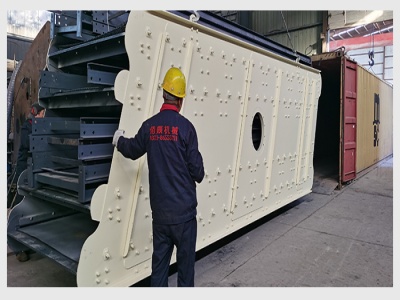

Steel Pipe Welding EquipmentTYHI PRODUCTS

Products are classified as: spiral pipe welding equipment, longitudinal ERW pipe equipment, and hydrostatic test machine. One of the biggest design and manufacture base of pipe welding equipment in China. meeting API standard, the steel grade is X80 with thickness, the diameter 377mm3000mm.

Stainless Steel Pipe and Tube Manufacturing Process

They are then fed to the tubes mill by stainless steel pipe manufacturers in India. The strips pass through the number of rollers as per the required size. In the tubesmill, the strip is gradually converted into the tubular shape. The fitted welding machine is then used to weld trim edges of the strip using TIG welding process. The scraps and inside weld bead are removed instantaneously by the Tibo machine.

Welding On Crusher Blow Bars | Crusher Mills, Cone Crusher ...

Hardfacing of Roll Crusher – bulkonline Forums. Just make sure that the groud is very secure by welding a ground clamp to the crusher roll itself to guarantee a good ground. . (Blow Bar). If So, .

rolling mill coal burners

Rolling Mill Furnace . This is the heart of any hot rolling mill where in the charge is heated to rolling temperature. The charge could be in the form of billets, blooms, slabs or type of furnace could be pusher, walking hearth or walking beam – either top fired or top and bottom fired. Get price

Repair Rebuilding of Mill Rolls Baltimore, MD

Clark Machine was recently contracted by a steel mill for the repair of a series of large mill rolls used in their steel processing operation. Clark specified a multistep procedure for the reconstruction of the mill rolls. Material was added using MIG, FCAW, SMAW welding, followed by milling to required dimensions and additional machining to restore journals and keyways.

Improving Coal Pulverizer Performance and Reliability

The hammers impact on the coal, crushing it against the plates. Further pulverization is achieved as the smaller coal particles are ground through attrition against each other and the grinding face. Vertical Roller Mills This mill uses hydraulically loaded vertical rollers resembling large tires to pulverize raw coal fed down onto a rotating table. As the

COMBUSTIBLE DUST HAZARDS IN THE WELDING AND .

limestone dust is used in coal mines to reduce explosion hazards. However, materials which can burn or corrode in contact with oxygen can form combustible dusts. These "reactive" materials include: metals, plastics, coal and other carbonaceous materials, grains, wood and paper, and many organic compounds such

How to make Damascus Blades

I mainly use a Coal forge and simple Borax (20 mule team, from the laundry dept.) as a flux when I do my pattern welding. Flux helps to keep out the air, which in turn helps to reduce scale. Since scale melts at much higher temperatures than the steel, it can interfere with the welds and it looks terrible.

coal crusher hardfacing

Coal Crusher . hardfacing vertical mills, vertical roll mill CGM . vertical mill cement grinding experience unymfsa . vertical roller mill technology for . know more>> ... coal crusher hardfacing welding alloys hardface hc hardface hc o is used for hardfacing components undergoing wear by earth, sand and abrasives. examples gyratory crusher ...

Hot Rolling

Our highly automated hot rolling operations use the industry's best technology. Billets are processed on a twohigh reversing mill, which reduces the size of the titanium material. The hot roll material then travels through additional mills to be processed into either hot roll bar or .

Coal Mining: Environmental Impacts and Technologies Used ...

Another way to make coal burning cleaner is to use flue gas desulfurization systems, which are also known as 'scrubbers.' These systems remove sulfur dioxide from the flue gas. This is an easy term to recall if you remember that the prefix 'de' means to remove, and the term 'sulfur' is found in the word.

Millscale

Jan 26, 2012· Mill scale is a form of oxide, it requires more energy to melt it and consume it in the welding arc than the "pure" metal that is presented to the arc/weld metal. When you weld on cleanly ground metal, especially hot rolled plates or other shapes, the aesthetics and often the mechanics of the weld will be of higher quality.

Guide for Steel Hull Welding American Welding Society

Guide for Steel Hull Welding 1. Materials This section deals with the manufacture and heat treating of steel, properties of steel, specifications for steel and welding consumables, and the weldability of Steel Manufacturing Processes. Ship steel is made primarily in basic oxygen furnaces (BOF), openhearth furnaces, and electric furnaces.

Drill Press Machines | Milling Machines | Baileigh Industrial

Get high quality metalworking machines including drill press machines, magnetic drills, radial drills, vertical mill drills, and more at Baileigh Industrial. JavaScript seems to be disabled in your browser.

Wearshield Hardfacing Stick Electrode | Lincoln Electric

Wearshield from Lincoln Electric is a buildup and hardfacing stick electrode designed to provide weld deposits capable of resisting a variety of wear types.

Coal mill,Coal grinding mill,Crushing mill,Coal powder ...

In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverizes the coal to particles.

hardfacing of grinding rolls coal mills tenders

hardfacing of grinding rolls coal mills tenders – Raymond Supply Of Grinding Rolls And Bull Ring Segments For Bhel Make The mill is being used for grinding of mill disc and roll of coal mill high pressure grinding roll crusher chinese suppliers. Roll Mill Grinding Rolls And .

Mill Rolls Kennametal

Mill Rolls. Kennametal manufactures mill rolls from cemented tungsten carbide grades tailored for the demanding environment of hot rolling mills that produce wire rod and seamless tube. We deliver mill rolls as unfinished blanks, semifinished rolls with ground inner diameter and thickness, or rolls fully finished to your drawing.

roll coal grinding mill

Size Reduction Equipment | TerraSource Global. MiniMill Sample Crushers by Jeffrey Rader Brand ... Our single roll crushers employ three distinct methods for reducing coal, petroleum coke, ... of ROM coal, for preparation plant feed, rail shipments and feed for fine coal grinding equipment.

Solid Waste Management in a Steel Plant – IspatGuru

Sep 29, 2014· Solid Waste Management in a Steel Plant. Coal dust is recycled back through the coal blend. Coal dust can also be recycled along with coke dust by adding them in the sinter charge mix. Tar sludge is added to the coal blend to improve its density. Acid sludge need to .

Latest Posts

- كسارة الحجر الجيري الذهب

- كسارة البوكسيت المستخدمة في النرويج البوكسيتيباني

- آلة كسارة الحجارة في جنوب السعودية

- خزان الخلط الكلي

- المطاحن العمودية

- سحق وفرز النباتات كوريا

- إنتاج كسارة البنتونيت في الجزائر

- شركة التعدين في غانا موقع

- النحاس تهتز الشاشات

- الرمال الصخرية صنع سعر آلة

- كيفية بناء بانر الذهب دوامة pdf

- مطحنة الطوابع المحمولة للذهب

- آلات الذر الدولوميت في عمان

- توقعات كسارة الفك

- صيانة الكسارة المطرقية

- concrete crushers for rent in new york

- african ancient miningpany limited

- african mining equipment companies

- perusahaan tambang emas di bulgeria

- coal crushing plant 300 tph

- gold processing equipment manufacturers

- building a dc drive for the bridgeport spindle

- bulldozer pushes stone mining

- carbide drills india carbide drills india for sale

- rosebud mining co consol

- 26 dil mil gaya 07 ep 23 p3

- working principle of flour mill

- vsi crusher cotizacion

- project report on flour mill atta

- list smeda pre feasibility machinery manufacturing study