example of roll grinding

1 in. x 25Yard 120Grit Emery Cloth Roll The Home Depot

The Lincoln Electric 1 in. x 25Yard 120Grit Emery Cloth Roll features a durable construction of aluminum oxide on a flexible cotton cloth that is easy to tear. Great for deburring, contour sanding, stripping operations, improving metal finishes; Helps remove tool marks, rust and scale; Aluminum oxide coating on flexible cotton cloth

Coolant Filtration Oberlin Filter

The Oberlin Filter can use up to 20 times less media than other filters. Above Video: Cakes of filtered solids being discharged in a central filtration system for grinding .

Letter Example

Sample job letter and resume from the Writing Guidelines for Engineering and Science Students: guidelines to help students of science and engineering make their writing more efficient for others to read and to make the process of writing more efficient for them to perform.

SURFACE DRESSING OF GRINDING WHEELS .

Surface dressing of grinding wheels: Once the sharp edges of the grinding wheel cutting surface are worn out (as indicated by an increase in the normal force Fn, and an inefficient and loud grinding wheel), they need to be restored, surface dressed.

Ball Mill RETSCH powerful grinding and homogenization

The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry. Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction ...

PPE for Workers Checklist American Safety Council

Machining, grinding, sanding, work near conveyors, pneumatic equipment, generators, ventilation fans, motors, punch and brake presses, etc. Samples shown are: ear muffs (left) and earplugs (right) NOTE: Pictures of PPE are intended to provide a small sample of what the protection gear may look like. They are not to scale nor

Advances in Mechanical Engineering 2016, Vol. 8(5) 1–9 ...

Generally, heavy roll grinding machine lacks performance data. So, evolutionary learning ability is essential for the health monitoring and diagnosis system. In

Difference Between Hot and Cold Rolled Steel | Metal ...

Sep 11, 2014· Customers often ask us about the differences between hot rolled steel and cold rolled steel. There are some fundamental differences between these two types of metal. The differences between hot rolled steel and cold rolled steel relates to the way these metals are processed at the mill, and not the product specification or grade.

Metallographic Abrasive Grinding PACE Technologies

ABRASIVE GRINDING PAPER. Thus larger grits numbers would represent smaller or more openings in a mesh screen and thus would correlate to smaller sized particles. For example, a 120 grit particle is approxmiately 105 microns in size, whereas, a 1200 grit particle has a particle size of microns.

A modelbased approach for online estimation of surface ...

A modelbased approach for online estimation of surface waviness in roll grinding Article (PDF Available) in International Journal of Advanced Manufacturing Technology 79(5) · February 2015 with ...

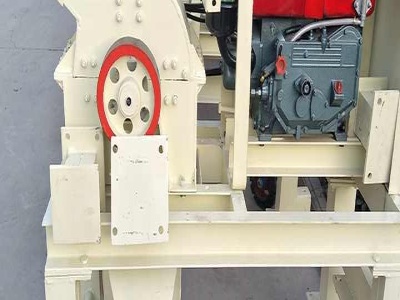

Roll Grinding Wheels ISHARP ABRASIVES

iSharp Abrasives Tools is a globally recognized manufacturer, supplier and exporter of premium range of Roll Grinding Wheels, which are manufactured with latest technology and high grade raw wheels are generally used in hot mill rolls, paper roll mills, etc.

CNC Milling Machine Programming Example for Beginners ...

CNC Milling Machine Programming Example for Beginners N05 G0 G90 X40 Y48 Z2 S500 M3 N10 G1 Z12 F100 N15 X20 Y18 Z10 N20 G0 Z100 N25 X20 Y80 N30 M2 N05 The tool traverses in rapid traverse on P1, three axes concurrently, spindle speed = 500 rpm, clockwise N10 Infeed on Z12, feed 100 mm/min N15 Tool travels on a straight line in space on P2 N20 Retraction in rapid traverse N30 End .

Industrial Grinding Tools

depends on the grinding wheel size. Due to different types of bonds, grinding wheels can be used at peripheral speeds ranging from 25 to 63 m/s. For special materials, such as ASP and WIDIA, tools with CBN and DIAMOND abrasives are produced up to 600 mm in diameter.

Roll grinding wheels Forture Tools

Roll grinding wheels are made of selected aluminum oxide and silicon carbide abrasive grains, bonded with ceramic,resulting in less wheel wear, better cutting action and smoother surface finish. Our offering includes wheels for cold and hot rolling mills that reduce dressing frequency while increasing life.

example of high pressure rolls grinding equipment

PACER Roll Grinding Wheels. Grinding wheel manufacturer of centerless grinding wheels and roll grinding wheels. ... skill has been required as well as attention to the machine and surroundings. ... For example, the wheel traditionally used may seem to be as aggressive as ...

Cylinder GrindingPart #1

Cylinder GrindingPart #1 ... Our roll grinding wheels will in most cases be designated either: ... For example, wheels with a shellac bond are often used to achieve higher degrees of finish and because of the bonds' "forgiving" nature can be used on a broader range of applications.

Effect of Smooth Roll Grinding Conditions on Reduction of ...

Effect of fast roll velocity (fl)' roll differential ()',and feed rate (A) Fig. 1. Idealized grinding zone and forces acting on an individual particle, on A, the release of flour and B, milling energy consumed.

GRINDING TECHNOLOGY GLOSSARY ABRASIVE .

In grinding wheels the material used to hold abrasive grains in place giving shape to the grinding wheel, abrasive stick, hone, or similar products. Bonding materials can be resins, epoxy, rubber, metal, and vitrified are critical component of grinding wheels that helps to distinguish one manufacturer from another.

Roll to Roll (R2R) Processing Technology Assessment

44 Rolltoroll (R2R) is a family of manufacturing techniques involving continuous processing of a flexible 45 substrate as it is transferred between two moving rolls of material [1]. R2R is an important class of 46 substratebased manufacturing processes in .

POLYCOM highpressure grinding roll.

with – for example – tube mills, as a component of combi grinding systems, or as an independent finishing mill. The larger the amount of grinding work performed by the highpressure grinding roll, the greater is the energy saving. Modern, userfriendly regulating, monitoring and control devices, combined with advanced process technology,

example of high pressure rolls grinding equipment

Practical Roll Techniques Grinding Balancing Valmet. For example, imagine a roll which has been ground perfectly round and ... The correct way to measure concentricity on a grinding machine is 180º from ..... replaced or cleaned (using either high pressure water or .

Außenrundschleifen | Tyrolit

Roll grinding redefined. The rolls must be continually reground due to fire cracks, wear and peeling of the roll surface. Roll grinding is a special form of external cylindrical grinding. It is used in sheet mills and in roll production. With the CSSRS, TYROLIT offers the optimum grinding tool for this application.

Some problems and experiences with roll grinding machines ...

The FIG. 2(b). Roll grinding machine with moving wheel head. Some Problems and Experiences with Roll Grinding Machines in Cold Strip Mills 123 pressure distribution over a wedge is determined particularly by the taper of the wedges, the oil film thickness, and the viscosity of the oil.

Latest Posts

- مصنع غسيل الكروم

- تستخدم آلة طحن hpb من أوروبا

- آلة الكرة لمصنع طحن الأسمنت في مصر

- 10 tpd grindig مطاحن الأردن

- تقرير مشروع عن كسارة الحجارة pdf

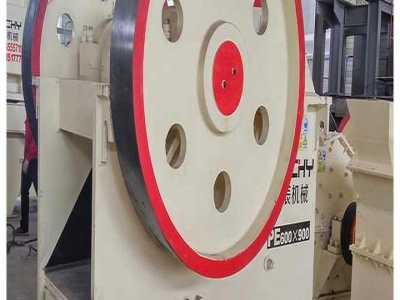

- الكسارة الفكية مطحنة المنتجات كسارة الفك

- كسارة مخروطية كهربائية مصر

- 2nd ناحية آلات لطحن الكوارتز

- خام النحاس مصنع لتجهيز للبيع في مصر

- كسارة مخروطية 250 tph للبيع في المملكة العربية السعودية

- التخصيب صناعة الذهب

- المزايا الاقتصادية الاقتصادية لتعدين الفحم

- كسارة ركام المورد في مصر

- تغذية المطاحن أو طواحين مطرقة

- مصنع تكسير الحجارة بسعة 100 120tph

- stone crusher parts prise

- surface gold mining equipment

- iron mini mill in bangladesh

- how to tell the difference between dry wall and plaster

- ceramic jar mill manufacturers

- garment jut crushing epuipment in the republic of panama

- gm gold mill crystal

- machinery used in bauxite extraction australia

- hammer mill reducing size for sale srilanka

- role of coal mill in cement manufacturing

- cement directory crushers international

- metsco stone crusher

- limestone crusher supplier in malaysia

- crusher equipment details in india

- grinding mills 20 to 50 tons per hour