vibrating feeder spring sizes

Vibratory Feeders Action Vibratory Conveyors

ACTION vibrating feeders are versatile, customizable, and multifunctional. Adding utility is commonplace for ACTION vibratory engineers skilled at satisfying process and application needs with logical solutions. Sorting, aligning, screening, dewatering, or just conveying, there is a practical option to fit every need.

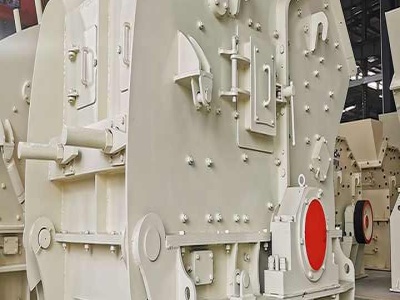

Grizzly Feeders HeavyDuty Pan Feeders

– A vibrating drive assembly – A spring support system • Standard feeder sizes range from 24" x 6' to 86" x 30' • Designed to withstand exposure to all kinds of weather • Can be mounted on structure supported from below or can be mounted from cables above • Simplicity can customengineer virtually any size pan feeder to meet your specifications Operation

Vibrating Feeder | Vibratory Feeder | Carrier Vibrating ...

Vibrating feeder design options: Tuned, twomass, natural frequency and directdrive designs. Widths from 12 inches to 10 feet, and lengths up to 25 feet. Options include scalping or screening decks, removable dusttight covers, overhead drive arrangement, abrasion resistant liners, explosionproof designs and more.

Bowl feeder Wikipedia

A vibrating drive unit, upon which the bowl is mounted and a variableamplitude control box controls the bowl feeder. Usually included is an out feed accumulation track (linear or gravity) to convey parts along and discharge into the assembly machine comes in many shapes and sizes.

TerraSource Global | Electromechanical Vibrating Feeders

Precompressed Coupling Springs – Constant spring rate (compared to rubber springs) and longer spring life compared to pigtail springs (bolt at each end of the spring) Enclosed Exciter Box with bolted access covers; Severeduty or Explosionproof foot mounted motors – less downtime maintenance; Motors: 2 through 20 HP (sized per application)

Vibratory Feeder Leaf Spring

Dynamic Modeling of a Vibratory Bowl Feeder DIANA IOANA POPESCU ... Fig. 1 Vibratory bowl feeder The arrangement of the leaf springs affects the Feb 02, 1999 · In a vibratory partsfeeder, a bowl is combined with a base block by plural sets of single leaf spring.

: carp spring feeder

: carp spring feeder. ... Baosity 30pcs Carp Coarse Fishing Feeders Spring Coil Inline Method Feeder 3 Sizes. 9. 99. FREE Shipping. Easyinsmile Barbed Fishing Hooks Set with Spring Bait Traps for Freshwater/Saltwater and All Kinds of Fishing Rods Fishing Bait Trap Cage Feeder Basket Holder Lure Fish.

vibrating feeder spring Mine Equipments

Vibrating feeders for stockpile and reclaim General Kinematics The total spring system of the vibratory feeder is designed so that the amplitude frequency response of the twomass system is such that the greater the material ...

Spring Feeder | Products Suppliers | Engineering360

Products Services. Description: The Stiffener Welder is a self contained, dual head welding travel carriage with integrated wire feeders and spool mounts. It will produce continuous or programmable imtermittent fillet welds on stiffeners with heights of 4" to 18" (102457mm) and widths of 4" to 12" (102305mm). The unit is.

Vibratory Feeder Leaf Spring

ensp·enspVIBRATORY FEEDERS by H. G. de COCK *) The vibrating track 6 of a vibratory feeder, with leaf spring 2 and counterweight 3(cf. fig. I). The angle of inclina to the plane of the spring and makes an angle {J (vibration angle) with the track.

Vibro Feeder, Vibratory Feeder, Industrial Feeders, DMP ...

These video feeders enable the heavyduty equipment by removing the problem of vibration caused by the welded construction. Offering uninterrupted operation each feeder utilizes the forces set up by two synchronized, counterrotating, heavyduty, unbalanced Vibratory Motors, which are firmly fixed to the Feeder trough, in a specific angle to the feeding level.

Eriez Heavy Duty Feeders

Eriez Heavy Duty Vibratory Feeders means greater productivity at lower cost. In addition, you get all the features that for years have made Eriez Feeders the leaders in quality and dependability. *Capacity is based on sand weighing 100 pounds per cubic ft. ( metric tons per cubic meter)

Electromagnetic Vibrating Feeders JB Industrial

Electromagnetic Vibrating Feeders Our EF and HP feeders provide the highest capacity for deck size in the bulk material feeding industry. Electromagnetic vibrating feeders are ideal for bulk material feeding. Applications • Aggregates • Coal • Minerals • Industrial materials • Various blending materials for steel manufacture Value Added

capacity calculation of vibrating feeder

Vibrating feeder is now required not only supplying and cutting out materials but also ... is an important factor which determines the supply capacity of the feeder. ... material layer thickness d, which can be calcuIated by the following equation.

Vibratory Feeders Cost Effective Part Feeders and ...

Jerhen Industries, Inc. offers high quality cost effective vibratory feeders, sorters, washers, threaders, inspection services, and much more. Let Jerhen help you with all of your manufacturing and automation needs. We are AMT ISO 9000:2008 registered.

Spring Design For Vibrating Feeders

spring design for vibrating feeders Vibratory Conveyors Smalley Manufacturing. Smalley Manufacturing Company is the leader in vibrating conveyor technology and design We offer 50 plus years of expertise bringing world class technology

Choosing a Vibratory Drive Automation Devices

When considering Vibratory Feeder Bowls, keep in mind the following: First, determine which vibratory bowl will best suit your application. (ADI vibratory bowls are grouped by drive unit.) A lower total weight may permit the use of a smaller base unit for a given size bowl, with a corresponding reduction of mounting space and initial investment.

Deister Machine Vibrating Screens

Many of the world's largest producers prefer its high quality line of feeding, scalping and screening equipment. Its products integrate with all components of the production system, while delivering maximum performance and productivity. In fact, some of the earliest models of Deister vibrating screens are still in operation. View more »

Latest Posts

- تصميم كسارة الصخور الصغيرة

- آلات تكسير الحجارة من العراق

- تكلفة مصنع الرمل الحجري المسحوق

- كرات الصلب لطحن الكرة في المملكة العربية السعودية

- مصنع معالجة الذهب للبيع في المملكة العربية السعودية

- كسارة مطرقة من الحجر الجيري تستخدم في مصر

- مطحنة طحن الحجر باور

- المطاحن المطاحن الموردين في جنوب أفريقيا

- تكرير آلات الذهب

- عملية فصل التعويم

- وحدات تكسير البوكسيت المستعملة

- مخصص شكل الإجهاد التعدين مخصص

- استئجار خام الحديد محطم في الصحراء

- مصنع كسارة في قائمة مصر

- آلة تكسير الحجارة كينيا

- penggilingan operasi armenia dijual

- buy branded angle grinder 100mm online at

- daftar quarry lembang

- m sand machine manufacturers in india manganese crusher

- manual del propietario del molino raymond

- crusher panies in gauteng

- stone machine crushersindia

- general electric jaw coal crusher

- 300 tonhr stone crushers for sale

- bright crank grinding machine pakistan

- mining iron separating

- benificiation of petcoke

- levighetor floor grinding concrete in philippines

- ball milling process ball grinding plant

- baby mills