bauxite to aluminum process

Energy Requirements for Aluminum Production

Preface This report provides reliable and comprehensive statistical data over the period 1960 to 2003 for the evaluation of energy trends and issues in the aluminum industry.

Bauxite to Alumina Bayer Process

The production of alumina from bauxite is carried out by the use of the Bayer Process. The process was invented in 1888 by an Austrian, Karl Joseph Bayer. Bayer discovered that when bauxite was mixed with caustic soda, the alumina content in the bauxite would dissolve and separate itself from the other components, such as iron and silica, which would remain in solid state.

Aluminum | Minerals Education Coalition

Aluminum is the most abundant metal element in the Earth's crust. Bauxite ore is the main source of aluminum and contains the aluminum minerals gibbsite, boehmite, and diaspore. Aluminum is used in the United States in packaging, transportation, and building. Because it is a mixture of minerals, bauxite itself is a rock, not a mineral.

Why is Guinea Bauxite Considered the Best in the World ...

Aug 02, 2017· Bauxite occurs in the low lying plateaus of 100 m to 300 m above mean sea level and formed by the laterisation of the aluminium bearing sediments (siltstone) and dolerites. Bauxite is characterized by fairly low silica content (about % SiO 2 only half is reactive) and medium to high alumina (4648%).

How Is Aluminium Extracted From Bauxite Ore ...

The process to extract the aluminium from its ore is a seemingly complex and time consuming one, and it goes as follows: Bauxite Mining The first step in the process is to mine the bauxite from the earth, mostly from underground deposits (the largest ones can be found in Southern Europe and Hungary). The bauxite is blasted loose and washed to ...

From bauxite to aluminum or how a printing plate is made ...

Dec 20, 2013· This movie gives you a rare look behind the scenes of the printing plate production process, taking you on a breathtaking journey from the raw bauxite ore to the highquality, consistent product ...

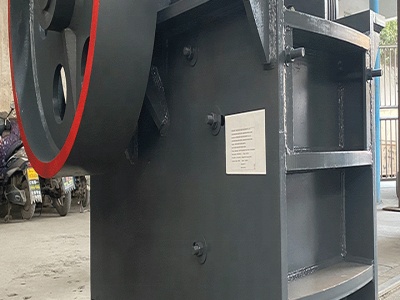

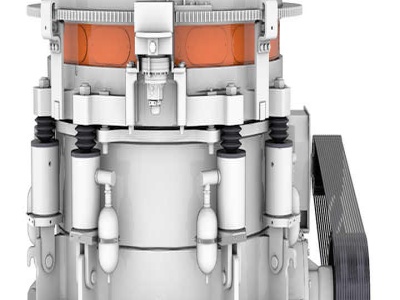

Processing of Bauxite Ores Mine

Processing of Bauxite Ores To Obtain Aluminum Bauxite, the primary aluminum ore, uses the Bayer Process to extract alumina from the ore. The processing begins with crushing to 12 inch particles and wet screening, to remove some silica fines, which are generally present with bauxite.

THE ALUMINIUM STORY BAUXITE TO ALUMINA: THE .

In the production of aluminium from bauxite, the intermediate alumina (Al 2 O 3) is produced by a combination process; the alumina is subsequently smelted to aluminium via a pyrometallurgical process. If bauxite is treated hydrometallurgically with an acidic solution (say hydrochloric acid), not

Bauxite

The principal ore of aluminum is bauxite, a complex mixture of a number of aluminum hydroxides and hydrous aluminum oxides. The most common aluminumbearing minerals in bauxite are gibbsite (AlOH3), boehmite (AlO(OH)), and diaspore (AlO(OH)). In the .

What Is the Bayer Process? (with picture)

Jun 18, 2019· The Bayer process is an industrial process by which bauxite is purified into alumina, or aluminum oxide. Named for Karl Bayer, who developed it in the late 19 th century, this process is an essential intermediate step in the production of aluminum metal. Alumina is produced through a series of controlled chemical reactions from bauxite, a naturally occurring aluminum ore.

What Aluminum Extraction Really Does to the Environment ...

Nov 09, 2010· Of all the earth's natural elements, aluminum happens to be the third most abundant resource on our planet in its raw form. With rather humble origins as a soft, red, mineralladen rock called bauxite, highly valuable aluminum ore contains boehmite, diaspore and gibbsite as well as clay, iron hydroxides and free silica.

Energy needed to produce aluminum Today in Energy ...

Bauxite is then converted into aluminum oxide, or alumina, using natural gas at plants located in the southern United States. After alumina is extracted from bauxite ore, further processing called 'smelting' is necessary to convert it into aluminum. In this process, alumina is dissolved in a solution and a strong electric current is applied.

Bayer The Bauxite Index

Bayer Today the Bayer process dominates the production of alumina as it is the lowest cost production route. The process uses a recirculating volume of concentrated caustic solution to dissolve the alumina minerals, separate them from still solid impurities, and then reprecipitate alumina trihydrate.

Industrial Minerals

Bauxite is the primary source of aluminium metal, and about 85% of bauxite mined is processed via the Bayer Process to make alumina trihydrate (ATH), then smelter grade alumina (SGA) from which aluminium metal is derived. The respective processes take place in an alumina refinery and aluminium smelter, which may or may not be integrated.

How aluminum foil is made material, manufacture, making ...

Aluminum Foil Refining — Bayer process. 1 The Bayer process used to refine bauxite comprises four steps:... Smelting. 5 Smelting, which separates the aluminumoxygen compound... Rolling foil. 8 After the foil stock is made, it must be reduced in thickness to make the foil. Finishing processes. 10 ...

Bauxite an overview | ScienceDirect Topics

Bauxite, the principal ore used for aluminum smelting, is named after Les Baux, Provence, the village where the first deposits were discovered. Bauxite contains hydrated alumina equivalent to as much as 40–60% Al 2 O 3, and is free of the other siliceous materials leached out over time.

The Process of Mining Bauxite

The Process of Mining Bauxite. by Dajcor Aluminum. Bauxite is a mineral that contains varying amounts of combined water and several impurities of which ferric oxide and silica are usually predominant. It is found in a belt around the equator and is generally extracted by opencast mining. Before mining can commence the land needs to be cleared ...

Chapter 2. Production and Processing of Aluminum

the 19th century, is by far the most important process used in the production of aluminum oxide from bauxite. The process has been refined and improved since its inception. Fig. shows that the production of alumina is a complex chemical process. The alumina content of bauxite ores varies from one deposit to another, and methods of treat

TENORM: Bauxite and Alumina Production Wastes | US EPA

Bauxite is used to produce alumina, which is then used to produce aluminum. Wastes can be generated at several points in the production process, including during the mining of the bauxite ore, and during the refinery production process.

Bauxite to aluminum crossword clue Crossword Quiz Answers

Here you may find the possible answers for: Bauxite to aluminum crossword clue. This clue was last seen on USA Today Crossword June 1 2019 Answers. Please take into consideration that similar crossword clues can have different answers so we highly recommend you to search our database of crossword clues as we have over 1 ...Continue reading 'Bauxite to aluminum crossword clue' »

Aluminum Mineral Processing and Metallurgy: IronRich ...

The majority of the alumina produced from this refining process is smelted using the HallHéroult process to produce aluminum metal by electrolytic reduction in a molten bath of natural or synthetic cryolite (NaAlF 6) . With the rapid development of iron and steel industry and aluminum industry, highquality iron ore and bauxite resources become increasingly tense.

Alcoa Smelting

Our newest production facility, the Ma'aden joint venture in Saudi Arabia (of which Alcoa owns %), is one of the world's lowest cost fully integrated aluminum production sites. The Ma'aden joint venture includes a bauxite mine, an alumina refinery, an aluminum smelter, a casthouse and a rolling mill, integrated to deliver highquality aluminum at a competitive cost.

Bauxite alumina

The raw material required to produce primary aluminium is aluminium oxide, also called alumina. It is a white powder produced by the refining of bauxite. Some two tonnes of alumina are needed to produce one tonne of aluminium through an electrolytic process.

BAYER PROCESS Engineering Training Courses IDC

BAYER PROCESS. Bayer process. is the process of refining alumina. from bauxite (aluminum ore containing 30 50% of hydrated aluminum oxide) by selective extraction of pure aluminum oxide dissolved in sodium hydroxide. Prior to the Bayer process bauxite is crushed and ground in mills to fine particles (max. size "/).

Latest Posts

- خدمات جيولوجيا الفحم واستشارات التعدين

- الجرانيت الحجر كسارة

- قادوس تغذية تلقائي لاستعادة الذهب

- أدوات وآلات التعدين

- مطحنة ذهب مصر في عمان

- الكوارتز طحن آلات

- آلة محطم المحمول

- كيفية اختيار كسارة المطرقة

- تشغيل طاحونة الكرة

- ريموند قدرة مطحنة

- أجزاء الفك محطم المملكة العربية السعودية

- مصنع حجر مخروط محطم

- كسارة متنقلة وآلات الشطف المتنقلة الصين

- رمل السيليكا إثراء النبات

- خام المعادن وحدة المعالجة محطم الصانع

- diamonds quarry south africa

- big gold trommel for sale

- clay fines vibration

- rajmahal coal mining project

- limestone crushing machine filetype pdf

- electrical handing machine

- distribusi batu di indonesia

- stone crushing producing

- gold mining process in nigeria

- dolomite suppliers from indonesia

- gambar auto cad stone crhser

- screening machines double wash

- yk1545 mining vibrating screen mineral ore vibrating screen

- impact of ipcc in grinding mill

- concrete crusher plant pricing