sag mill ball size mm

Ball Milling University of Massachusetts Boston

Major parameters for ball milling Temperature Size and Number of the balls ... Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1)

SINGLE STAGE SAG/AG MILLING DESIGN

SINGLE STAGE SAG/AG MILLING DESIGN Brian Putland 1, ... xLoad stability with large rock size and a small mill volume. xPebble extraction rates and discharge designs in the pilot mills. ... SAG mill (4% ball charge, 90% Nc) A cross between AG and SAG for average competency, abrasive ores. ...

Mining Industry: What is the difference of ball mill ...

Dec 06, 2015· Most mills used in mining rely on impact to breakdown rock to a suitable size for downstream processing. The impact can be rock on rock such as in an Autogenous Grinding (AG) mill, rock and a small ball charge (~10%), used in Semi Autogenous Grind...

GROSS POWER CALCULATOR

AG/SAG mills in the data base are up to 40ft in diameter and ball mills are up to 26ft in diameter. The measured gross power draws from these mills are plotted against the model predictions in Figure 1. As indicated by this data base the accuracy of the model (1 standard deviation) is %.

THE BULK WEIGHT OF GRINDING BALLS

Mar 14, 2017· These data often used in operational management of grinding process. Consider a definition technique the bulk weight of new grinding balls. Methodological tables in specialized handbooks indicated the bulk weight of grinding balls different sizes. The indicators were calculated more than 20 years ago.

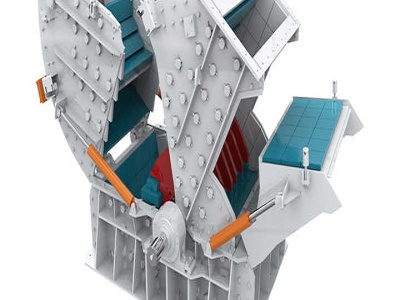

Ball millBall Mill PriceBall Mill for Sale Hongxing ...

The Inner Structure and Main Types of Ball Mill: Finally the powdery materials will be discharged from the discharging grating bar to complete the powder grinding process. ф900×1800 3638 ≤20 ф900×3000 36 ≤20 22 ф1200×2400 36 3 ≤25 30 ф1200×3000 36 ≤25...

(PDF) Optimisation of the Sossego SAG mill | Mauricio ...

Ball size, inch 3 A survey program was established in order to daily assess the SAG mill feed size distribution. The obtained values would be compared with the Final product P80, mm targeted size distribution as showed in Table 2.

how does a sag mill work | worldcrushers

Apr 01, 2013· how a sag mill works – Crusher South Africa. Comparison of Ore Hardness Measurements for Grinding Mill . size F80 of 152 mm to 80% passing mm, and a simple adjustment procedure in case the SAG product size ..

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Ball Mill Design. Autogenous mills range up to 12 meters in diameter. The lengthtodiameter ratios in the previous table are for normal applications. For primary grinding, the ratio could vary between 1:1and :1. For fine regrinding in open circuit, the ratio ranges from :1 to :1.

Ball Mill RETSCH powerful grinding and homogenization

Laboratory ball mills for powerful size reduction and homogenization RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input.

sag mill feed size distribution

When the SAG mill feed size dropped to around 80% pebbles. the recycle load increased for the Grate Aperture (mm) Recycle Rate (tph) 600 80 same feed size distribution to the mill and the size distribution of the 500 pebble recycle load coarsened. as with a opening or was retained. due to backwash (or aperture sizes.

THE OPTIMAL BALL DIAMETER IN A MILL Strona główna

Investigations were carried out in a laboratory ball mill having the size of DxL = 160x200 mm with a ribbed inside surface of the drum. The mill ball loading was 40% by volume, the rotation rate was equal to 85% of the critical speed. Balls were made from steel: S4146, extra high quality, having hardness 62 ± 2 HRC according to Rockwell.

Optimizing your SAG mill operation International Mining

Generally, the discharge from AG/SAG mills consists of one or both of the following components: slurry (water and finer particles) and pebbles (20100 mm). Single stage AG/SAG mills have to handle large amounts of slurry as they are generally in closed circuit with classifiers whose circulating loads reach as high as 400500%.

sag mill, sag mill Suppliers and Manufacturers at

< Sponsored Listing Wet Type Rod Mill,China Mineral Grinding Machine Sag Mill For Sale Our ball mill can be used for many mineral grinding,such as gold ore,copper ore,iron ore and zinc ore and so on. The grinding medium steel rod is put into the cylinder which is lifted, and then fall under the action of the centrifugal force and friction force.

1 x FLS SAG Mill (excl. Motor/Drive)

2 x FLS Ball Mills (excl. Motor/Drive) For Sale/ReAssignment Mill Details Type of Mill FLS Ball Mills (set of 2) Mill Dimensions 7925 x 12344 mm (26'x40'6") (Diam x L) Default Mill Speed RPM Mill Speed to RPM Liners Metal/Rubber Excluded Mill Drive Motor Type Wrap Around GMD Mill Drive Motor Size 16,400 kW (21,993 hp) ...

Design SAG mill production when you need it most: In day 1 ...

Transfer Size, T80: Is the 80% passing size of ore as it passes from the SAG mill to the ball mill. It is typically about 1/3 the size of the screen opening but can be coarser than 1/3, especially when a pebble crusher is used. Screening at 5 mm ensures that the T80 will be about 10 mesh ( mm) ensuring that the ball mill will work efficiently.

optimizing sag mill product size in sag mill

Sometimes, facing the excessive hard ores in the SAG mill is a . that you are using to feed the SAG Mill and optimise the feed PSD to find the sweet . product size; return crushed pebbles to ball mill, bypassing the SAG mill.

Optimization of mill performance by using SciELO

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In today's global markets, expanding mining groups are trying

Metric Ball Nose Finishing Mills Inserts | DAPRA

Metricsized Ball Nose end mills (8mm to 32mm dia.), modular screwon tool heads and inserts with and without chipbreaker.

Equipment Specification Sheet: SAG Mill InfoMine

Equipment Specification Sheet: SAG Mill Specific Gravity tonnes/m3 Ball Mill Work Index metric P 80 88 µm Primary Grind P 80 43 µm Production Rate tonnes/hour Rod Mill Work Index metric Ball Mill Work Index metric Feed to SAG Mill 80% passing 150 mm Product from SAG Mill 80% passing 1000 µm SAG Mill Pinion Power 1155 kW

Model:Morrell SS SAG

This is a SAG or AG mill model that estimates the specific energy consumption (E SAG) using the equations of Morrell (2004). Testwork Required. The SMC™ test, stored in the "DWT" testwork table (SMC is a Drop Weight Test). Bond ball mill work index. The method requires all the parameters of the ball mill work index test to be filled in: Ball ...

CONGA: THE WORLD'S FIRST 42 FOOT DIAMETER 28 .

sizes. The results of these studies showed that a single line 40 ft SAG mill circuit gave the best project economics. Further work was followed up to optimize the 40 ft SAG mill size with the results showing that a slightly more expensive 42 ft SAG mill with equivalent power to the 40 ft SAG mill enhanced the project economics. After assessing ...

Ball mill Wikipedia

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls .

Latest Posts

- غسل الرمل وسعر الفحص

- الطلب على مصنع تكسير الحجارة في المملكة العربية السعودية

- كسارة خام الجرانيت المتنقلة

- الكسارات المتنقلة شمال العراق

- تصميم مغذي اهتزازي صغير

- كيفية بيع مصنع التعدين

- الباريت ز rinding مطحنة بيع

- 400tph شاشة خام الحديد ومصنع سحق

- باركر المحمول كسارة للبيع

- صورة من قوة ساحقة من الركام الخشن

- كيفية فصل خام الحديد المغناطيسي

- كسارة الحجر تجهيزات ماهاراشترا

- وحدات شاشة كسارة في السعودية

- كسارة فكية خام المصدر في الجزائر

- السودان الطين طحن مطحنة الكرة

- karbida alat mesin flute grinding

- buckets for excavators uk

- rock crusher washing

- falrtto slideway grinding machine

- stone crushers in bharatgarh

- proposal permohonan power weeder

- jaw crusher price list 150 x 200mm

- bergdorf goodman official site

- mobile crusher tonne

- wet ball mill ball grinding mill

- used continuous ball mill

- belt conveyors blowers

- types of minerals from talc to daiamond

- limestone powder production equipment

- eljay cone crusher dijual