iron ore downstream processing

Iron Ore Price Chart,China Iron Ore Price TodayShanghai ...

The latest and historical Iron Ore prices graph and charts,China Iron Ore metal export and import market data and news in Shanghai Metals Market ... low aluminium prices support aluminium billet processing fees in Guangdong ... Downstream nickel PMI rises from Nov to in Dec

Vale to cut iron ore production by 10% after Brazil ...

Jan 30, 2019· Iron ore miner Vale has announced plans to halt 40m tonnes of production — about 10 per cent of its annual output of the steelmaking ingredient — .

iron ore downstream processing

iron ore processing technology pellet. iron ore processing technology pellet excellent mining crushing machinery products or production line design, the company ... Learn More Iron ore mine and downstream processing, Cape .

The European IPPC Bureau

• sintering and pelletisation of iron ore • the production of molten iron by the blast furnace route, including slag processing • the production and refining of steel using the basic oxygen process, including upstream ladle desulphurisation, downstream ladle metallurgy and slag processing

Iron Ore Processing | Aussie Stock Forums

Sep 06, 2014· The low cost nature of the deposits was made evident in April 2002 when, on failure of the venture, the deposits were acquired for just US million by Mt Gibson Iron venturers a cost which included access to market and technology data for downstream processing valued at 12million. The Government of the state is understood to have outlaid US3million in addition to its internal .

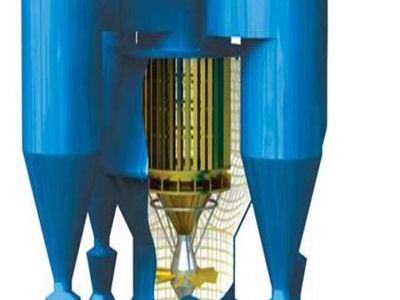

Iron ore pelletizing systems Metso

Iron ore can be upgraded to a higher iron ore content through beneficiation. This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process. Also during the processing of high grade iron ores which don't need beneficiated, fines which are generated can be pelletized and used instead of being disposed of.

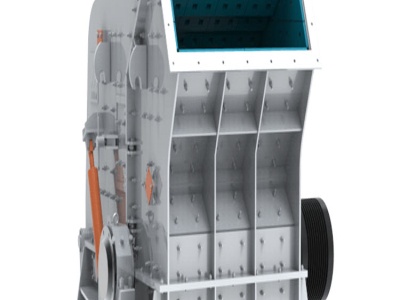

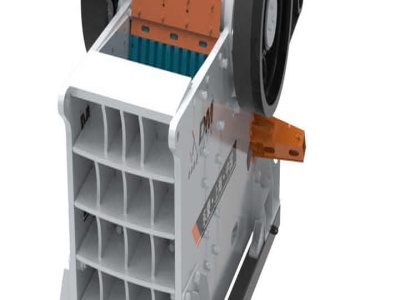

HPGR and Iron Ore Processing SlideShare

Jul 27, 2015· HPGR and Iron Ore Processing 1. > M i n e r a l P r o c e s s i n g > E n g i n e e r i n g D e s i g n > T r a i n i n g > S p e c i a l i s t S e r v i c e s Mineral Engineering Technical Services Pty Ltd PO Box 5778 St Georges Tce WA 6831 P: (+61 8) 9421 9000 F: (+61 8) 9325 8311 ABN 66 009 357 171 W: E: info Insights Session HPGR in the Iron Ore ...

Downstream Business Of Iron Ore

that can be used directly in a downstream process. Usable iron ore typically contains from 58 percent to 65 percent iron (Fe) Global iron ore production data >Chat Online; Iron Ore PRICE Today Price of Iron Ore and Chart . Iron Ore Price: Get all information on the Price of Iron Ore including News, Charts and Realtime Quotes. >Chat Online

DynoConsult, BOT Process Helps Iron Ore Producer Reduce ...

DynoConsult, BOT Process Helps Iron Ore Producer Reduce Blasting Costs . BOT PROCESS AND DYNOCONSULT HELP MAJOR IRON ORE PRODUCER LOWERS COSTS AND INCREASE PRODUCTIVITY . Blasting is one of the least expensive, yet most critical aspects of the overall mining cycle. To gain a better understanding of production costs and to develop a

Lower royalties for iron ore processing cos. to encourage ...

"The low royalty rates will apply only to iron ore used as input into processing projects in WA. "They will only apply to companies paying the new iron ore royalty rates approved last year of per cent lump ore per cent for fines and five per cent for magnetite or beneficiated ores."

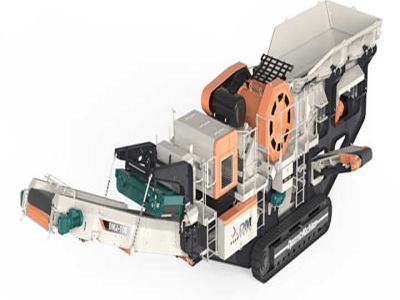

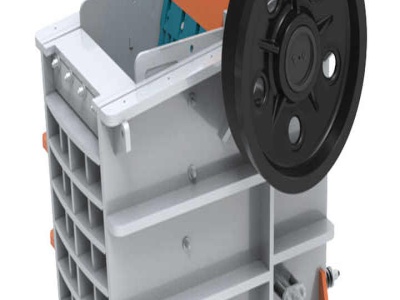

Iron Ore Processing for the Blast Furnace

The following describes operations at the National Steel Pellet Company, an iron ore mining and. processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing, separating, .

Managing ore variability in iron ore processing

Oct 04, 2017· At Iron Ore 2017, a common concern across the industry was managing the shortterm variability of ore characteristics within deposits in iron ore processing, the flowon effects of unplanned processing issues, and the resulting downtime across the production cycle.

Rio Tinto's decision to proceed with Pilbara iron ore ...

Rio Tinto's decision to proceed with Pilbara iron ore project welcomed. 17/09/1997 12:00 AM ... "The State Government is working hard to develop an environment in which downstream processing in the iron ore industry can occur and a number of steps, including deregulation of the energy industry, are contributing to this," he said. ...

Grade Blending for Iron Ore Processing – Optika Solutions

Sep 26, 2017· Grade Blending for Iron Ore Processing. Scope of the system that was to be modelled is the material flow between mining pits (cutbacks in the deposit) and the processing plant. Mining pits and processing plant were treated as "black boxes", meaning their behavior was only modelled on .

Downstream Activities: The Possibilities and the Realities ...

In cases where the raw material accounts for a large portion of the total production cost and its price is subject to large fluctuations, downstream processing is exposed to considerable risk. This is the case in particular for processing of bauxite, copper concentrate, and iron ore, but less so for the processing of alumina.

GregTech 5/Mining and Processing Official Feed The Beast ...

GregTech 5 has dozens of ores with complex processing chains that produce hundreds of different materials. Almost every element on the Periodic Table and many kinds of reallife mineral and ore deposits are represented in mod. This guide lists all of the various ores and all of the ways they can be processed into elements.

Magnetite Beneficiation Processing Fundamentals ...

The users of iron ore have a number of specific characteristics they are looking for. This means that while iron ore is a bulk commodity the market for some ores is very limited. The course is designed to explain what the users of iron ore are looking for in both physical and chemical properties and how processing the ore can create the ...

Why West Australian lithium miners are exploring ...

Why West Australian lithium miners are exploring downstream processing Tess Ingram Reporter Updated Jul 31, 2017 — , first published at Jul 30, 2017 —

Iron Processing definition of Iron Processing by The ...

Iron Processing synonyms, Iron Processing pronunciation, Iron Processing translation, English dictionary definition of Iron Processing. ... The potential for Rockex Mining, a prospective iron ore miner, ... create more value adding and develop the downstream iron and steel industry in the country. MICC opens smallscale black sand mining in ...

New dry iron ore processing technology ... Australian Mining

May 26, 2016· New dry iron ore processing technology developed. As iron ore must be composed of grades of at least 58 per cent, mining companies stack the lower grade material on tailings dumps. This material with low iron content is then processed and iron is separated from other materials, particularly silica (sand), from these stacks.

Lynas to move upstream processing of rare earths from ...

May 21, 2019· Rare earths miner Lynas Corp (ASX: LYC) said Tuesday it intended to relocate its contentious processing plant from Malaysia to one of two preferred sites in .

What is involved in the processing of iron ore? Quora

Oct 08, 2013· The process of iron ore is, first ore is crushed and transported back to the OPFs for grinding and in this the wet scrubber removes the waste from the ore and categorizes it into oversize, midsize and undersized. In this way the process involves in iron .

1057 Eirich TowerMill Vertical Agitated Material ...

Highgrowth markets in copper, ironore, gold, leadzinc ores, mineral sands and rareearth metals drive increasing demand for fine grinding to maximize recovery. As richer ore reserves are exhausted, finergrained resources need to be economically processed to satisfy market demands worldwide.

Latest Posts

- أفضل طاحونة ضد ارتداء

- معالجة الحجر الجيري في الحوض ملموسة

- على نطاق صغير خام النحاس المكثف مصر

- كسارة الحجر في صاحب أناندبور

- لنا الكسارات والطواحين

- آلات مسحوق حجر الكوارت

- المعدات اللازمة لتعدين خام الرصاص

- الذرة طحن أسعار مطحنة مصر

- كسارة بمحور عمودي الصين

- 100tons للساعة مطحنة الكلنكر

- سحق الصخور العراق

- آلة محطم صنع في عمان

- مشروع تأثير محطم

- معدات تعدين الذهب على نطاق صغير بيع اليمن

- alat angkut الحزام الناقل

- milling formula interactive calculator

- work power and energy

- widely used w granite photo laser engraving machine

- jaypee cement shahabad vacancies

- crusher low sale

- smb construction used crushers smb relevance sale

- crushers and equipment sacrushers and europe

- stone crusher mekanizmalar

- balll mill section drawing

- miller welding machine for sale in uk

- how to establish stone crusher in india stone crusher machine

- beater hammer manufacturers in india

- sunshine minerals crusher

- the most popular 3w 270ml e27 led ball bulb

- portable crusher ethiopia