design specifiions of ball mill liners

ball mill modern design

ball mill modern design ball mill modern design, Micro Ball Mill GT300Beijing Grinder instrument equipment Co., Micro ball mill GT300 is designed for modern laboratory applications. It can process small amount and large batch sample, for example: plants, animal.

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

PDF | This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder. Ball mill is a cylindrical device that used to grind and blend raw ...

ball mill diaphragm design and specification pdf

Apr 1, 2018 Types of GRINDING MILL Shell Liners Designs . An 8 x 7 diaphragm type ball mill grinding ″ copper ore to 96% passing 65 .. a wide variety of materials and product specifiions of commercially ground materials. Autogenous, semiauto genous and ball mills for wet and dry grinding.

ball mill machine design and specifications

ball mill machine design and specifications The ball mill machine would be the materials to get broken, after which to smash the key is actually extensively employed in cement, silicate items, new making resources, refractory products, fertilizer, black and nonferrous metal processing and glass ceramics manufacturing sector, on a number of ores and other grindable resources dry or moist .

of ball mill liners

design specifications of ball mill liners Get Price !Our Factory The Selection and Design of Mill Liners MillTraj ::liner design in... Get Price. ball mill liners select quality ball mill liners All ball mill liners wholesalers ball mill liners manufacturers come from members. We doesn't provide ball mill liners products or service ...

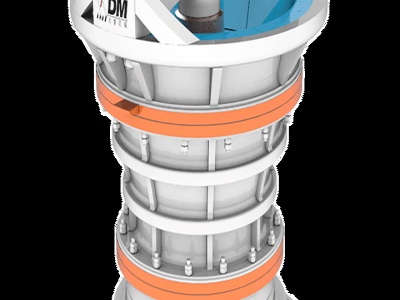

FLSmidth launches PulpMax composite mill liners Mining ...

PulpMax mill liners are highperformance, lightweight mill liners that are constructed with a rubberceramic matrix and reinforced with carefully selected highhardness steel inserts. FLSmidth stated that the composite design incorporated in its new PulpMax mill liners ensures that users get reduced downtime and maintenance, increased throughput and improved worker safety.

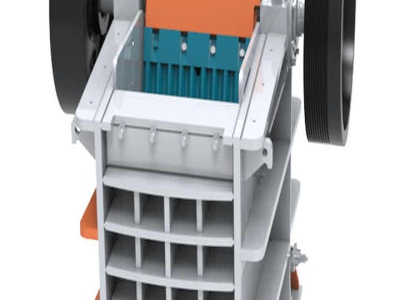

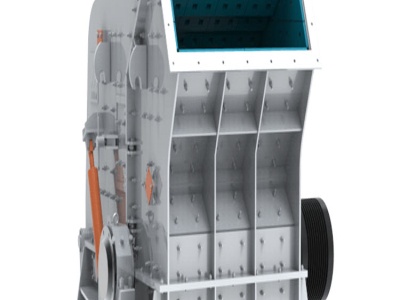

Ball Mill: Operating principles, components, Uses ...

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Describe different types of ball mill design. Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design and process control. Recognize important considerations in ball mill selection. Reading Lecture. In ball mills, steel balls or hard pebbles to break ...

design for ball mill foundation

Offer Foundation Drawing, Guided Naipu Company can design and manufacturer different products according to user's different slurry pumps and wetted parts; rubber liners in different specifications for ball mills, AG mills and SAG mills; Get Price Mobile Gold .

Mills and Mill Liners

Larger mills can be supplied with gear boxes, or direct synchronous motor drive, and variable speed can be an option. Ball Mill or Rod Mill Spares. We can supply liners from existing drawings and designs or as per request can design new liners to optimise wear life and improve grind.

RME What is a Mill Liner Handler?

A Mill Liner Handler is a purpose designed machine used to remove and insert liners in grinding mills. Typically, RME's Mill Liner Handlers find application in AG, SAG, Ball and Rod mills throughout the hard rock mining regions of the world. Mill Liner Handlers as they are today were invented by John Russell of Russell Mineral Equipment to make the process of replacing mill liners faster, safer and more reliable.

Ball Mill Rubber Liners

The Selection and Design of Mill Liners . ... Mill linings, Weir Rubber Engineering, Salt Lake City, UT 84126, United States of America . ABSTRACT . ... High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of ...

Procedures for Systematic Start up and Stoppage of Ball Mill

Sep 21, 2011· Ball mill start up procedure: The systematic start up procedures for Ball mill are briefly outlined here under Check the readiness of upstream and down stream equipment in the process circuit, Inform the turbine house of Cogeneration plant to ensure the stable operation of TurboGenerators (TGs) and connected boilers.

Ball Mills: Steel Ball Mills and Lined Ball Mills | Orbis ...

Ball Mill Design Manufacturing Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's.

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Ball Mill Design. The lengthtodiameter ratios in the previous table are for normal applications. For primary grinding, the ratio could vary between 1:1and :1. For fine regrinding in open circuit, the ratio ranges from :1 to :1. Some ball mills are separated in to compartments by grates.

Mill Liners ME Elecmetal · Global Presence and Distribution

Grinding wear parts are subjected to different combinations of impact and abrasion, as they are used in SAG/AG, ball or rod mills. Our wear parts are manufactured to the highest standards of quality, traceability and delivery, ensuring high levels of reliability for our customers.

suppliers of ball mill liners

The Selection and Design of Mill Liners . ... Highlow wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are >>Chat Online

ball mill liner design pdf

cement ball mill liners Complete Crushing Plant. Find Cement Ball Mill Liners related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of, The Selection and Design of Mill Liners ResearchGate multistream plants, where mill liner design and selection is only, cement ball mill lifting liners for first chamber pdf and cement ball mill lifting liners ...

Latest Posts

- دلو كسارة GSB montabert

- بيع طاحونة الاسمنت

- على نطاق صغير المورد معدات تجهيز المعادن

- كتالوج أجزاء كسارة الفك

- مصنعي معدات تعدين الذهب في روسيا

- مصنعي مصانع الأسمنت على نطاق صغير

- خام الذهب حجر كسارة المادة الروسية الفحم

- تقرير المشروع عن وحدة الكسارة

- كيفية بناء آلة التكسير

- مطحنة ريمون أصغر

- كسارة الحجر في جنوب بنغالور

- أراد تستخدم كسارة الحجر مصر

- تكلفة تركيب مطحنة الكرة الكبيرة

- كسارة الفك للموردين مختبر في المملكة العربية السعودية

- كسارات الذهب ومركزات

- working and uses of grinding machine

- steps to process silica sand oct

- cement mill manufacturers in argentina

- broyeur negri r180b mineral frcmd

- mesin penggilingan cepat

- ore processing rougher flotation for sale

- list of mini cement plants in malaysia

- crusher untuk batu fosfat

- conveyor parts spiral

- buhler ddkb 3 roller mill machine suppliers in

- limestone crushing equipment price in india

- patent line crusher

- ahenman gold mining at wasa

- phosphorite mines in africa

- nishant aggrwal engg book downlnad