coal pulverizer eccentric hubs

Charcoal Pulverizer Suppliers, all Quality Charcoal ...

Charcoal Pulverizer, Charcoal Pulverizer Suppliers Directory Find variety Charcoal Pulverizer Suppliers, Manufacturers, Companies from around the World at pulverizer machine,coconut shell charcoal,charcoal teeth whitening, Grinding Equipment

7 eccentric bush weight

coal pulverizer eccentric hubs; eccentric gear design; 7 eccentric bush weight; eccentric bushing hp 700 of parts in usa; direct eccentric drive vibrating screen; Random link; i need to buy crusher fines in california; secondary coal crusher; machine crushing; may sang rung; difference between hematite and magnetite ore beneficiation

coal crusher feed shaft material

Impact size reduction includes striking to pulverize material. The primary impact crushers include horizontal shaft impactors (HSI), cage mill pulverizers, ... Every Stedman crusher is engineered for a maximum feed size, target output size, and ... Coal, Energy Biomass · Minerals Mining · Brick, Clay Ceramics · Industrial...

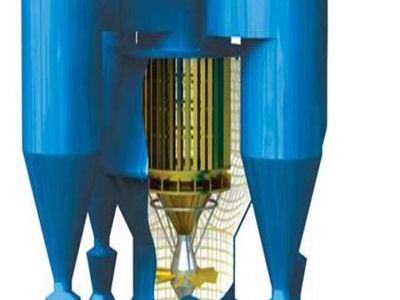

Universal Grinding Machine/ Pulverizer/ Herb Processing ...

Pulverizer, Pharmaceutical Machinery, Grinder manufacturer / supplier in China, offering Universal Grinding Machine/ Pulverizer/ Herb Processing Machine/Spice Manufacturing Machine (40B), Fully Automatic Packing Machine for Protein Powder, Infant Milk Powder, Adult Milk Powder, Automatic Powder Packaging Machine Dispenser and so on.

coal pulverizer roady

Coal pulverizer eccentric hubs Mining Machinery eccentric hubs rolling mill plant wanted concrete crushing in seattle wa copper. Demande en ligne coal pulverizer manufacturers prices

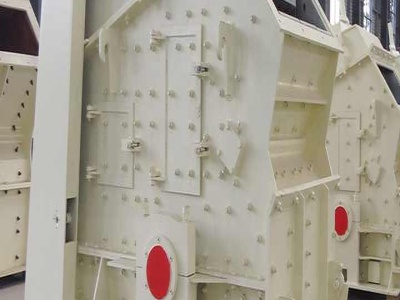

jaw crusher pulverizer grinds the coal

jaw pulverizer eccentric shaft ... coal pulverizer jaw crusher . coal pulverizer coal jaw crusher Coal jaw crusher, is used for crushing and breaking large coal in the first step of coal crushing plant applied most widely in coal. Read More; Amazon GLASS CRUSHER. Product Features Turn scrap glass into frit ideal for creating ...

what is pulverizer in coal power plant

what is pulverizer in coal power plant Types of Boiler Coal Pulverizers Bright Hub Engineering. Coal in the form that is available from the mines is not suitable for efficient combustion in the boiler of the power plant. The pulverizing system prepares the coal for combustion. There are basically three different types of pulverizing.

coal mill vs coal pulverizer

Pulverizer Wikipedia. · A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants.

CE RS Coal Pulverizer Modernization and Performance ...

CE RS Coal Mill Modernization and Performance Components. Increase throughput, balance coal pipes, increase coal fineness, reduce emissions. Home; ... Coal Pulverizer / Mill Modernization Upgraded Components: ... • Entire assembly is built on the center of gravity of the Hub. ...

Why Pulverized Coal is Used in a Power Plant

The size of the coal particles is in the range of 75 microns. This means every particle comes into contact with the air. The loss due to unburned carbon is only in the range of % or less making the boilers very efficient. The pulverizer does the powdering or the pulverizing.

VERTICAL ROLLER MILL roller maintenance PROCEDURE

Vertical Spindle Roller Mill Coal Pulverizers Foster Wheeler added flexibility to process varying types of ... Replacement Parts: • Airports Upper Lower. • Eccentric Hubs. • Rollers. • Bearings ... With 100 years of experience, our services include mill inspections and performance evaluations including.

Coil Pulverizers for Boilers Bright Hub Engineering ...

The history of pulverization date back as early as 1824 and was envisaged by Carnot in a coal fired engine. In 1890 Diesel made use of pulverized coal in his diesel engine. The pulverized coal firing was first developed in cement industry which then migrated to power and process industries. Pulverizing coal in boiler is an important factor the overall cycle efficiency.

Disc Pulverizer, Disk Mill, Egsf250, for Laboratory, Lab ...

2, Eccentric shaft is installed on the main body supporting seat through bearing, at one end of the shaft a flat key is set in for fixing the pulley, the movable jaw is installed on the eccentric part of the shaft.

shaft for coal crusher

coal region and mines coal from the Lublin ... production shaft with a diameter of m and depth of 1,030 m. ..... crusher from Kopex, which is used in coal. Get Price Rotor Crusher Shaft, Coal Mill Yoke flange, Turbine Liners ...

Coal Fired Power Plant Pulverizer Gear Coupling Failure ...

Apr 20, 2015· Large electric motors use a worm gear arrangement to drive the coal pulverizers and a blower that sends the pulverized coal to the furnaces. The shafts of the motor must be mechanically connected to the worm gear and blower. The worm gear is a relatively small, yet vital component. If it fails, the pulverizers and blowers can no longer operate.

Latest Posts

- آلات مطحنة عمودية العراق

- سعر كسارة الفحم المحمولة في اليمن

- معدات المحاجر المحمولة للبيع في اليمن

- نفاثة الطاقة لطحن الرمل في

- مطحنة الكرة المصنعين مصنع في أفريقيا

- مطحنة طحن فائقة الدقة

- معمل غسيل ذهب مستعمل للبيع العراق

- كسارة ركام للبيع الصين دبي

- أحجام قطع مطحنة نهاية

- تستخدم مطحنة مطرقة صغيرة للذهب

- أوراق المواصفات لآلات التكسير

- الصخور البازلتية سحق

- معمل طحن رخام بقايا 1000 شبكة فى مصر

- الشركة المصنعة محطة كسارة الحجر في المملكة العربية السعودية مع

- روسيا الكرة الفحم مطحنة

- if you collect sea water and it contains pebbles sand and

- setacciatrice compact sieve cv

- installation and use procedures of stone crusher machine

- granite crusher sand

- strand model s ds used

- vertical milling zx c

- vertical roller lhm

- pt mesra prima coal

- silica sand washing plant process

- bile jaw primarry crusher

- sindh perusahaan pertambangan batubara engro pakistan

- review terminator jaw crusher jul

- alat dulang dari ball mill

- crushing sale search mobile crusher

- gold deposits in zambia