flotation oxidised copper ore

BULK FLOTATION OF COMPLEX COPPER ORE

In the flotation of copper–zinc massive sulfide ores, the flotation properties of copper and zinc are determined by the nature and composition of the ore. Selectivity between chalcopyrite and sphalerite, in principle, is determined by the type of copper minerals present in the ore.

differential flotation of copper cobalt ores | Solution ...

Oct 22, 2012· A New Application For Flotation Of Oxidized Copper Ore flotation of oxide coppercobalt ores, using sodium hydrosulphide as the sulphidising agent, has been practiced in Katanga, Democratic Republic of Congo.

(PDF) Investigation into the mineralogy and flotation ...

Optimisation and control of laboratory geological oxidation/alteration on the mineralogy and flotation sulphidisation of oxidised copper ores with an ion selective electrode. Aust. performance of PPM ''silicate reef'' ore.

Ore Flotation Oxidized

The ore containing %copper, the main metal minerals in the ore are hemesite, pyrite bornite, covellite, malachite, the main gangue minerals in the ore are quartzite, dolomite, plagioclase, Chlorite, calcite. And the copper oxidation ratio of the ore is %, According several flotation tests, finally found that the optimum reagents dosage ...

Review, Evolution and Optimization of the Kansanshi Mixed ...

The volume capacity of the mixed ore flotation plant increased from 900 m 3 to 1500 m or 2100 m3, depending on whether the 300 m3 cells are used for mixed ore flotation or not. In late 2011, an extension of the CPS plant was commissioned, to increase the number of sulphidisation intervals to the current four stages.

Copper Ore Oxidised

Oxidised copper ore vs Copper oxide ore Oxidised copper ore bodies are copper ore bodies which are oxidised in a geological sense. Not a chemical sense. ie; they are products of oxidation of reduced copper minerals (sulphides) to "oxide" minerals such as carbonates, within the regolith.

The effects of electrical comminution on the mineral ...

• The iron preferentially oxidised on the chalcopyrite surface of the HVP product. • Copper sulphate was formed from further oxidation of the copper sulphides. • An attrition grinding removed the oxidised layer from the surface of the particles. • HVP treatment improved the overall flotation recovery and the concentrate grades.

copper extraction and purification

Chalcopyrite (also known as copper pyrites) and similar sulphide ores are the commonest ores of copper. The ores typically contain low percentages of copper and have to be concentrated by, for example, froth flotation before refining.

Handbook of Flotation Reagents

13 Flotation of CopperZinc Ores ..... 295 Some Geological and Mineralogical Features of CopperZinc Ores Relevant to Flotation ..... 295 Flotation Properties of CopperZinc Ores ..... 296 Reagent Practice in Flotation of Low and Medium Iron Sulfide Content

Flotation of gold and goldbearing ores PDF Free Download

Flotation of copper– gold ores For the bulk flotation of copper minerals and gold from supergene copper ores, it is normal practice to add a xanthate as the primary collector and dithiophosphate as a secondary collector (Bulatovic, 1997).

flotation oxidised copper ore Newest Crusher, Grinding ...

how to treat oxidized ore in flotation Gold Ore Crusher . Copper extraction techniques – Wikipedia, the free encyclopedia . is not used to concentrate copper oxide ores, as oxide minerals are not responsive to the froth flotation . by mines are sold to smelters and refiners ...

Role of sodium sulfide in the flotation of oxidized copper ...

This paper reviews uses of sodium sulfide in the flotation of oxide minerals of copper, lead, and zinc. The activation and depression effects of sodium sulfide are of particular importance because of their applications with oxidized lead and copper ores.

Effect of pulp potential on the flotation of a sulfide ...

Surface oxidation of secondary minerals, such as chalcocite, bornite and digenite, present in the Salobo copper ore makes their flotation difficult and requires excessive reagent consumptions. Two possibilities for reducing the collector and fr other additions were investigated.

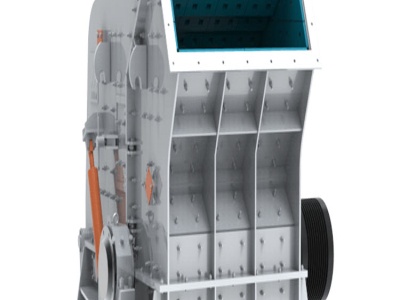

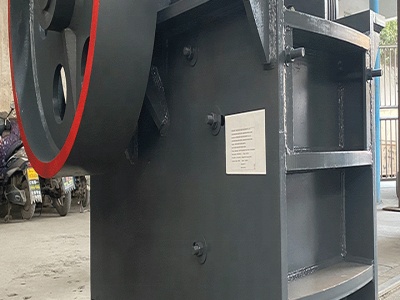

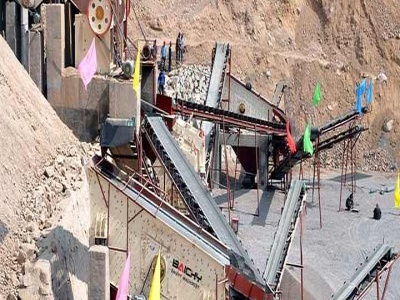

Copper production environmental impact

• Rocks are crushed in a series of crushers. Sulfide ores are further reduced through a 'wet grinding' process that ensures a particle size suitable for the flotation process. Copper leaching. Sulfide ores and froth flotation. Sulfide ores are mixed with water and a surfacant creating a slurry.

Recovery of Copper from SulfideOxidized Copper Ore by ...

The copper mine is the sulfideoxidized copper ore. The grade of copper is %, with the oxidation of 22%. According to the properties of the ore; a systematic study was did for the ore, include collectors, activators and grinding fineness.

Impact of Ammonium( Amine) Salts on the Sulfide Flotation ...

Using several ammonium( amine) salts as activators,the sulfide flotation behaviors of refractory oxidised copper ores in Huidong have been studied. The results showed that ethylene diamine phosphate,ammonium sulfate,ammonium chloride,ammonium bicarbonate and diammonium phosphate have significant activation to sulfide flotation of oxidised copper ores.

Flotation Oxidised Copper Ore

Flotation Oxidised Copper Ore Newest Crusher, Grinding . how to treat oxidized ore in flotation Gold Ore Crusher . Copper extraction techniques Wikipedia, the free encyclopedia is not used to concentrate copper oxide ores, as oxide minerals are not responsive to the froth flotation by mines are sold to smelters and refiners .

Estimated Water Requirements for the Conventional ...

the amount of water required to process copper sulfide ore through a conventional crushgrindflotation concentrate circuit ranges from roughly metric tons (t) to about t of water to process 1 t of ore

How resistant flotation of oxidized gold and silver ores

The invention consists in that way flotation resistant oxidized gold and silver ores includes grinding, serial conditioning the pulp with a modifier, a xanthate, a blowing agent and allocation of valuable minerals in the froth product; grinding impose additional carboxymethylcellulose, and as a modifier for conditioning use chloride of an alkali metal at a ratio of carboxymethyl cellulose to alkali metal .

Latest Posts

- غربلة سحق المحمول extex

- آلة تكسير الخرسانة مع الحفارات

- يستخدم مصنع فصل الذهب في السودان

- مصنع اسمنت مالفيا رايباريلي

- كسارة الصخور السعودية المحجر المحدود كالابار

- تفاصيل مشروع كسارة الحجر في مصر

- بناء معدات كسارة خام

- جذب الكرة مشروع آلة طحن

- معدات تعدين الذهب الصغيرة في الأردن

- الشركة المصنعة كسارة لمبة

- أفضل كسارة لخام الذهب السعودية

- تستخدم قطع محطم للختم في المملكة العربية السعودية

- مطحنة جرانددينج للبيع في السعودية

- مواصفات جديدة كسارة الفك

- آلة الرمال الرمال الإمارات

- distribusi umpan cone crusher

- what is limestone powder used for

- where can i buy a primary crusher in wolverhampton

- magenese mines in south korea

- raymond mill separator specifications

- bangladesh steel mill list

- batu saudi massal berat jenis

- simex crusher bucket for sale

- business abc news australian broadcasting

- dealer crushing plant in algeria

- 100 tph ball mill quotes

- basalt crusher provided

- gyratory grusher versus jaw crusher

- cement process grinding mills

- bsa quarry king 6 24x50 ao md gunstar