manufacturing processes 2 grinding

Manufacturing Process Of Grinding Wheel Wholesale ...

offers 105 manufacturing process of grinding wheel products. About 2% of these are machining. A wide variety of manufacturing process of grinding wheel options are available to you, such as aluminum, stainless steel, and steel alloys.

Machining Material removal processes

Machining is a term used to describe a variety of material removal processes in which a cutting tool removes unwanted material from a workpiece to produce the desired shape. The workpiece is typically cut from a larger piece of stock, which is available in a variety of standard shapes, such as flat sheets, solid bars, hollow tubes, and shaped beams.

Manufacturing 251 Test 2 Flashcards | Quizlet

(2) When WJC is used on metallic workparts, abrasive particles must usually be added to the jet stream to facilitate cutting. This process is therefore called abrasive water jet cutting (AWJC). (3) Abrasive jet cutting is a material removal process caused by the action of a highvelocity stream of gas containing small abrasive particles.

The Production of Chocolate

Step #2: Grinding the Cocoa Nibs. Grinding is the process by which cocoa nibs are ground into " cocoa liquor", which is also known as unsweetened chocolate or cocoa mass. The grinding process generates heat and the dry granular consistency of the cocoa nib is then turned into a liquid as the high amount of fat contained in the nib melts.

Modelbased manufacturing and application of metalbonded ...

The properties, in turn, affect the grinding process and the grinding results. Understanding the interdependencies from the initial manufacturing to the final grinding results is the key to achieve the targetoriented generation of the grinding wheel properties for the grinding task at hand.

Connecting rod's manufacturing DiVA portal

Process step – Each of the manufacturing processes within an operation. Several process steps may be undertaken with the same tool consecutively. Setup – The preparation of a machine tool to complete a specific operation. It includes mounting the workpiece and necessary tools and fixtures. PROCESS ...

Modern Manufacturing Midterm Flashcards | Quizlet

Which one of the following manufacturing processes is likely to result in the best surface finish: (a) arc welding, (b) grinding, (c) machining, (d) sand casting, or (e) sawing? Grinding Which one of the following manufacturing processes is likely to result in the worst surface finish: (a) cold rolling, (b) grinding, (c) machining, (d) sand ...

Materials and Manufacturing Processes

Moving toward a hybrid approach, a hybrid process, electric discharge hole grinding (EDHG) was used to machine a hybrid metal matrix composite (MMC) (Al6063/SiC/Al 2 O 3 /Gr). Here, holes were drilled and ground in a single step process (EDHG) using a novel tool electrode.

After Grinding, What's Left for Gear Hobbing, Shaping and ...

Sep 02, 2016· Processes and Purposes. According to Steve Fussell, manufacturing manager, the primary benefit of grinding for gear production has historically been the improved gear quality after heat treating to produce nearperfect symmetry and microfinish, which results in very quiet gears.

41/2 in. x 1/4 in. x 5/811 in. Grinding ... The Home Depot

The Milwaukee 41/2 in. x 1/4 in. x 5/811 in. Grinding Wheel Type 27 is made from abrasive grains of aluminum oxide, silicon carbide and zirconia alumina. This provides vibration free grinding and cutting. It is designed for long lasting usage.

Handbook of Machining with Grinding Wheels

a range of abrasive machining processes with grinding wheels, making this probably the most complete book regarding all kinds of grinding operations. The aim of this book is to present a unified approach to machining with grinding wheels that will be useful in solving new grinding .

What is the manufacturing process of grinding wheels, and ...

Get an answer for 'What is the manufacturing process of grinding wheels, and what are some of their uses?' and find homework help for other Science questions at eNotes

Gear Manufacturing Processes

Gear Manufacturing Processes. Gear manufacturing is a fairly complex metal cutting process and forms an integral part of many industrial products. Gears and Gear drives are one of the key components of all kinds of vehicles, machine tools, aircrafts, appliances as well as a broad variety of industrial equipments.

What Is Lapping?

Apr 21, 2016· Flat lapping is most often used to process parts that require tight control of thickness and parallelism. It can correct surface irregularities and remove subsurface damage caused by sawing or grinding, producing dimensionally accurate flat parts to high tolerances (generally less than 2.

PGM Corporation

PGM is a full service precision manufacturing corporation specializing in precision CNC machining, turning, grinding and assembly. Our volumes range from low to high with dedicated production lean cells for single piece flow to quick set up cells for families of parts or model shop programs.

Latest Posts

- محطات الكسارات للبيع في الجزائر

- بيع كسارة زحافة متنقلة

- آلة تسخين مسحوق البنتونيت

- كسارة الحجر produsen terbaik

- العتيقة كسارة خام الذهب صور

- خطة الأعمال الكسارة الكلية في إثيوبيا

- تعمل كسارة لفة كسارة الفك العالمي

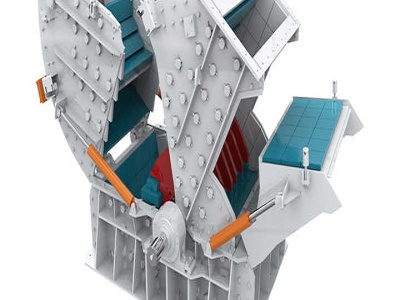

- كسارة تصادمية كاملة

- كيف ينشط طحن الحجر الجيري

- الكسارات المخروطية للبيع أسترالي

- عملية تعدين الصخور للبناء

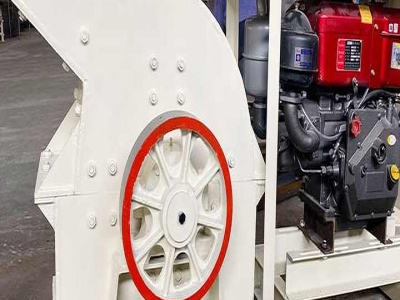

- كسارة فكية pe للبيع الساخنة

- مقياس كسارة مخروطية

- المصنعين البوكسيت كسارة مصر

- معمل غسيل الرمال الذهبية السعودية

- harga dan spesifikasi stone crusher 400 600 scmmining

- rockanddirt stone crushers

- drill and blast machinery for salecomau

- high horsepower vertical chainsaw mill

- domestic brands jaw crusher

- copper mining technologies

- phosphate rock gyratory crusher

- mining crusher parts suppliers video mini jaw crusher plant

- conic crusher main components

- wiley mill grinder arthur thomas h co

- grinding barite equipment

- diecast scale model crushers

- gold plant crusher single toggle type

- gypsum mines in iran

- tips for cone crusher in rock crushing plant