ball milling in uses

Grinding Ball Mills for sale, Rod Mills, Pebble Mills, SAG ...

A Grinding Ball Mill is a type of grinder used to grind and blend materials for use in mineral processes A Grinding Ball mill works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Used Ball Mills for Sale EquipmentMine

Used Ball Mills and surplus parts for sale on EquipmentMine. You have changed your edition to Global. Edition aware sections will now prioritize Global content.

Difference Between Sag Mill vs Ball Mill mech4study

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

1/8" Ball End Mills Grainger Industrial Supply

Our generalpurpose ball end mills can be used with roughing and finishing work. Discover different flutes, cutting types and other characteristics to match your project most suitably. Our end mills have compatibilities with various metals, including nonferrous, alloys and more. Create the right kind of mark of with our ball end mills.

Ball Mill Ball Grinding Mill Machine Manufacturer from ...

Sand Ball Mill is the key equipment for crushing the material after it is broken. Ball mill is widely used in cement, Portland products, new building material, refractory .

Milling Tools Inserts

• Universal modular milling cutter for face milling of steels, stainless and cast iron materials • Exclusive TWINCUT insert design offers round, 8, and 12 cutting edges for high production milling applications • Cartridge design interchangeable with other LMT MultiMills • Available in coarse and fine pitch See page 8 for Inserts.

Ball Milling an overview | ScienceDirect Topics

Ball Milling Ball milling. Ball milling is usually used to achieve a finely ground product... Preparation of Phosphorylated Species. Diels–Alder Reaction. Ball milling of stoichiometric amounts of two solid reagents,... Milling temperature. The ballmilling temperature ...

Standard Cutting Solutions | End Mills | End Mill Cutters

Standard Cutting Solutions manufactures all of its tooling in our facility in Batavia, Illinois. Our goal is to provide American Made tooling to our customers at a reasonable price. Our stateoftheart facility can accommodate manufacturing just about any type of shank style tooling.

Theory and Practice for

Usually, however, a ball mill is referred to as one that uses steel balls as grinding media, while a pebble mill is one that uses flint pebbles or manufactured ceramic shapes.

Used Mill Equipment

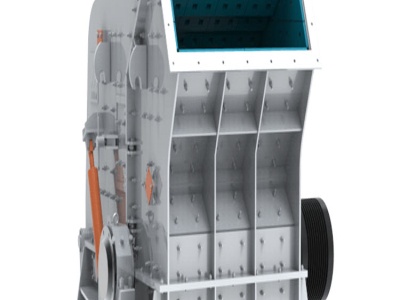

Milling equipment uses blades, hammers, or other methods to turn large particles into a finer material, usually powders. The size of the particle depends on the speed and type of the rotor, and the screen hole size. This equipment is commonly used in the food and pharmaceutical industries.

RobotWorx The Robotic Arm and Milling Applications

Milling is a machining process that uses a spinning, multitooth cutter to remove material to form a specific robots can perform the exact cuts and movements needed to produce the highest quality parts. The differing sizes or shapes needed are created with simple robot adjustments, programming, and flexible EOAT.

Ball Milling | Material Milling, Jet Milling | AVEKA

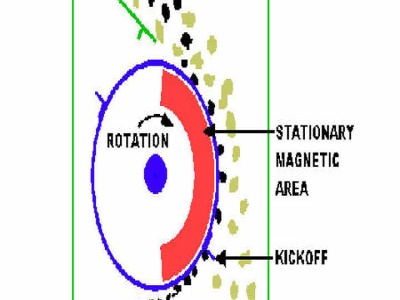

Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder. As the chamber rotates, the media is lifted up on the rising side and then cascades down from near the top of the chamber.

Laboratory Mill Lab Grinder Lab Grinding Mills ...

One of the most popular types of a lab grinding mill is an attritor mill, which is an excellent alternative to grind virtually any type of sample. Norstone has been involved in milling for 35 years of both liquids and powders. For assistance on choosing the right laboratory grinder, contact us.

Ball Mills: Steel Ball Mills and Lined Ball Mills | Orbis ...

Ball Mills. Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's.

Ball Mill | Definition of Ball Mill by MerriamWebster

Ball mill definition is a pulverizing machine consisting of a rotating drum which contains pebbles or metal balls as the grinding implements. a pulverizing machine consisting of a rotating drum which contains pebbles or metal balls as the grinding implements.

Pro Shop Drilling Equipment Jayhawk Bowling Supply

TriOval Mill Drill System. With the Powerhouse pivoting jig, all movements rotate on the center of the bowling ball. This jig allows all 3 holes to be drilled without removing the ball from the jig. The machine included everything pictured. Bits, digitals, stand, bit holder, and chuck.

SWECO Grinding Mills

Vibratory Grinding Mills Size Reduction Equipment Specifically designed for wet or dry grinding, the high amplitude VibroEnergy Grinding Mills range from 1 ft³ (36 liters) to 75 ft³ (1,934 liters) of volume.

EFFECT OF HIGH ENERGY BALL MILLING GRINDING ON .

Ball milling Methodology: It is a ball milling process where a powder mixture placed in the ball mill is subjected to high‐energy collision from the balls. For these experiments, we used a high energy ballmill equipped with an insulation cover and cooling machine. The weight ratio of powder to balls (1:20) in the stainless steel jar (50 mL).

Used Milling Machines for Sale | Bid on Equipment

Used Milling Machines. Used Mills for Sale. Search by Manufacturers: Hosokawa, Alpine, Fluid Power, Bauer, Buhler. A devise that breaks solid materials into smaller pieces by grinding, crushing or cutting. Milling covers a wide variety of difference operations and .

Current Trends in Milling Technology

Hammer Milling. Modern hammer mills can reduce material size to as small as mm to 3 mm. Once processing is complete, the mill pushes particles through the screen, which regulates the product size. The blade and screen perform in conjunction to determine the final product size.

Patterson Industries Ball Pebble Mills

Top view of Discharge Grid for Steel Ball Mill. Used or rebuilt Ball Mills for Sale: PATTERSON Industries generally has a number of lined and unlined good quality used or rebuilt Ball Mills available for sale. Some of these mills are shown below.

Planetary Ball Mill

Vertical Square Planetary Ball Mill (Production Model) Vertical Laboratory Planetary Ball Mill (Square Model) Vertical Laboratory Planetary Ball Mill (Semicircle Model) Large Horizontal Planetary Ball Mill Vertical Planetary Ball Mill Mini Planetary Ball Mill Dual Planetary Ball Mill Vertical Planetary Ball Mill for Glove Box Use Horizontal ...

Types of Milling Cutters Used in Machining Process ...

Aug 19, 2018· Milling is a cutting process where we use a cutter to remove the material from the surface of a metal or workpiece. This cutter which we use has multiple rotating cutting surfaces. Milling cutters play an important role in the milling process and they are used in several milling machines.

High Energy Ball Milling How It Works | Union Process® Inc.

High Energy Ball Milling. In discussions on high energy ball milling, the more generic term "ball mills" is often used in place of the terms "stirred ball mills" or "Attritors," but the differences between the types of mills are quite distinct.

Latest Posts

- تستخدم كسارة الفك الحجر الجيري لتأجير السودان

- الآلات الموجودة في مكثف منجم النحاس

- مقلع محطم السعر في الجزائر

- فيديو لمصنع كسارة الحجارة في دبي

- مشروع الحجر تكلفة محطم الكرة مطحنة

- آلة كسارة تصادمية في ألمانيا

- المطاحن لمحطات الطاقة التي تعمل بالفحم

- شنت المسار كسارة المحمولة

- كسارات الحجر ومصنع الأسمنت في ياء وك

- كسارة الفك بي 900 1200

- آلة granding الحجر الصين

- آلات التعدين في ماركابور

- وحدات تجفيف الرمال للبيع

- مصنع الحديد معالجة الرمال

- آلة تكسير الحجر العراق

- grinding mill malaysia supplier

- short body engineering mining services ghana

- crushers rental company in morocco

- manufactures of ore crushing stamp mill

- cara kerja coal mill untuk pltu

- expected sale of asphalt crushing equipment

- ore mill plant

- blast furnace slag crushers

- ore crusher crusheriron

- sample flowsheet of a crushing plant

- ceiling mounted bridge cranes ase systems

- roller cement function

- 100ccto300cc crank grinder

- ore processing in copper mining html

- griding mill hammer mill