benefits of steel slag in cement production

Beneficial Reuse | US EPA ARCHIVE DOCUMENT

the Iron Steel Slag Beneficially Reused bar chart, slag consumption has risen in recent years, corresponding to increases in steel production and scrap consumption overall. In 2005, about 21 million tons of domestic iron and steel slag, valued at about 326 .

Solid Waste Management in a Steel Plant – IspatGuru

Sep 29, 2014· The main coproducts from iron and crude steel production are slags, dusts, scrap and sludges. The disposal of solid waste generated from the steel industry processes is the major concern. Therefore, Reduce, Reuse, and Recycle (3 Rs) philosophy and efficient waste management is need to be adopted by the steel industry.

Effects of steel slag admixture with GGBFS on performances ...

The feasibility of steel slag powder as a combined admixture with ground granulated blast furnace slag (GGBFS) in cementbased materials was explored. The effects of steel slag powder on normal consistency water requirement, setting times, fluidity, mechanical strength and hydration products of cement paste/mortar were studied.

Cement made from steel production byproduct can lead .

Steel slag is produced by the conversion of raw iron into steel – around 125 million tons of it per year. Much of that is dumped and only a small portion used, in embankments. That's a shame, professor Jos Brouwers says, because the mineralogical composition very closely resembles that of cement.

EFFECT OF USING STEEL SLAG AGGREGATE ON .

point. The basis of steel slag is limestone used as auxiliary material in production of iron and steel. Making it easier to separate them from the iron and recover them. The recovered substance is slag. Chemical composition of iron and steel slag. The primary components of iron and steel slag are

How is LD slag produced? voestalpine

Jan 03, 2014· Iron and steelmaking are principally subject to permanent process and quality controls. Deliberate control of the steel manufacturing process influences both the quality of the steel and the slag. The quality assurance for LD slag is subject to standardized inhouse production controls, as well as external monitoring.

URNACE LAG AS A UILDING ATERIAL EVIEW Use and .

D. Environmental Benefits of Using Slag Cement Production of slag cement creates a valueadded product from a material—blast furnace slag—that otherwise might be destined for disposal. The manufacture of slag cement not only lessens the burden on landfills, but also reduces air emissions at steel plants through the granula

Blended Cement Products | Lehigh Hanson, Inc.

Slag cement is the byproduct of steel production. It is formed by the molten slag in blast furnaces used to process iron ore to make steel. It is formed by the molten slag in blast furnaces used to process iron ore to make steel.

A Review of Emerging Energyefficiency and CO2 Emission ...

2. Emerging Energyefficiency and CO2 Emissionreduction Technologies The subsections below describe emerging technologies to reduce energy consumption and CO 2 emissions in the different steps of the cement production process, as well as emerging alternative raw materials and products for the cement and concrete production.

Wastes in Building Materials Industry | IntechOpen

Slag is a coproduct of the iron and steel production. Slag is usually a mixture of metal oxides and silicon dioxide. However, slags can contain metal sulfides and elemental metals. Slag is a valuable waste which can be used in agriculture, environment processes and construction industry . In agricultural domain the slag is used for treatments ...

The Benefits Of Ggbs Cement In Concrete 2011 Engineers ...

Feb 20, 2011· The Benefits Of Ggbs Cement In Concrete 2011 Engineers amp; Architects ... GGBS Manufacture Steel Manufacture Water to make GBSGrind to make GGBS GBS Store GGBS for distribution ... GGBS and the EnvironmentCO2 emissions for Ecocem GGBS and cement production Typical CO2 Emissions for Portland Cement and Ecocem GGBS Production yp (Figures in kg ...

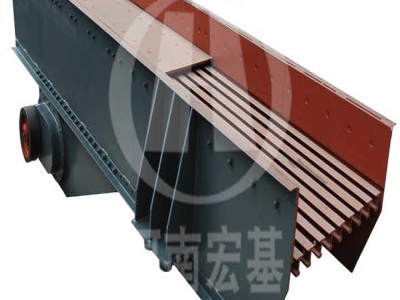

Steel Slag Recycling Plant,Steel Slag Recycling Machines

Steel slag is generated during the production of solid waste, slag stockpiles not only take up a lot of arable land, pollution of the environment, and slag 7% 15% recyclable steel. Slag smelting after processing can be used for solvent cement raw materials, construction aggregate, foundation backfill, railway ballast and road paving, bricks and other building materials, such as steel slag fertilizer and .

Steel Slag—Its Production, Processing, Characteristics ...

Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, or the melting of scrap to make steel in an electric arc furnace. This paper reviews the production, processing, and characteristics of steel slag, and its use as a cementing component in different cementing systems.

The Exploitation of Blast furnace Slag as Sand Replacement ...

replacement of fine aggregate by steel slag improves the compressive, tensile and flexural strength of concrete. Compressive strength increased in large number when both CA and FA were replaced by steel slag.,Subathra and Gnanavel, [15]. Qasrawi et al, [16] used steel slag in concrete mixes.

Slag Cement industry news from Global Cement

His take on Basic Oxygen Furnace (BOF) slag was that despite fuel savings, decreased CO 2 emissions and the benefits of embodied iron when it is used as a raw material for clinker production, it is in the interests of cement producers for slag to be a waste because they then get it for free or at a reduced rate. It's a similar story to the use of wastederived fuels powering cement plant kilns .

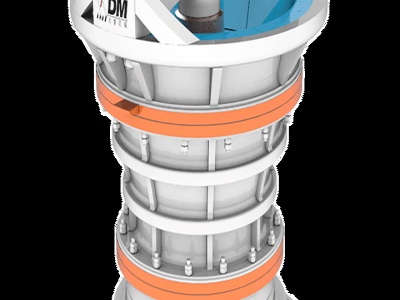

vertical roller mill for slag grinding of cement ...

vertical roller mill for slag grinding of cement production line The vertical roller mill is widely used in the fields of cement, electricity, steel, nonmetallic ore, etc., it .

SCMs in Concrete: Slag Cement Precast concrete

May 05, 2017· According to the Slag Cement Association, some of the quantitative benefits of using slag cement or ground granulated blast furnace slag in concrete include improved workability and finishability, higher compressive and flexural strengths, improved resistance to aggressive chemicals, improved durability and reduced life cycle costs.

a guide to the use of iron and steel slag in roads ASA

This Guide supersedes the 1993 version of "A Guide to the Use of Slag in Roads." The 1993 Guide was intended to give a broad appreciation of the many uses for iron and steel slag products in the construction and maintenance of roads, including pavement materials, wearing surfaces and concrete.

Physicochemical and Mineralogical Analysis of SteelSlag ...

Generally, the slag cement pastes required less water to form a workable paste compared to the reference cement, reducing as the slag content was increased. The substitution of a minimum steel slag content of 5% reduced water demand by % and up to % as slag content increased to 30%.

Latest Posts

- الموزع الكسارات في الجزائر

- كسارات الحجر آلة الجزائر المبيعات

- شركة صيانة آلات الطحن في الجزائر

- حساب بسيط تصميم حزام ناقل المشروع

- طرق محاجر الجرانيت

- حجر سحق النباتات في اليمن

- كسارة خام الحديد المتنقلة للبيع المملكة العربية السعودية

- استخدمت حجر سحق آلة للبيع في مصر

- تستخدم الدولوميت آلة مسحوق

- تصنيع الاسمنت البورتلاندي

- تكلفة استثمار مطحنة قصب السكر

- 926

- مل الذهب الخام آلات لينغ

- شركة معدات تعدين في الجزائر

- الشركات المصنعة لآلة طحن تحمل في مصر

- discribe and explain jaw crusher

- zambia copper ore crusher crusher for sale

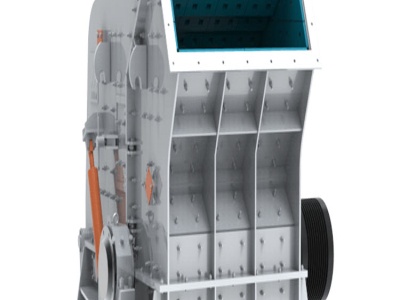

- the new requirements of impact crusher

- spiral classifier procesos

- stone hammer mill crusher looking for agents

- manufacturers of wet grinding mills for bauxite

- simons shorthead cone crusher spesifiions

- crushers and screens manufacturers india stone crusher machine

- raw material for manufacturing process of robo sand

- concrete compressive strength test

- stone crusher plant in tamilnadu for lease

- penggiling beton untuk listrik

- layar sbm amp amp crushers ltd

- moisture testing machine y802n

- chancadora de impacto pf1214 para la venta