why torsion shaft is required in cement mill

hardfacing cement crushers

hardfacing for stone crusire Crushing Plant . ... why torsion shaft is required in cement mill . Hardfacing ... » hardfacing procedure of a roller crusher ... Contact Supplier Hardfacing cone crusher – Grinding Mill China.

UNIT 7 SHAFTS Shafts IGNOU

UNIT 7 SHAFTS Shafts Structure Introduction Objectives Types of Shaft Materials for Shafts Shaft Strength under Torsional Load Stresses in Bending and Torsion Shaft Loading Shafts under Torsion and Bending Stiffness of Shaft .

Overturning Analysis Procedure

short drilled shaft foundations where the shaft's depth is governed by lateral loading and the required overturning or torsion resistance. Overturning Analysis Procedure Shaft foundations, supporting the structures noted above, are loaded laterally mainly by wind forces.

Md17 Shaft Design University of Northern Iowa

Shafts are mounted in bearings and transmit power through devices such as gears, pulleys, cams and clutches. Components such as gears are mounted on shafts using keys. Shaft must sustain a combination of bending and Shaft must sustain a combination of bending and torsional loads. August 15, 2007 3 Standard diameters of shafts 5 to 8 1/4 3 to 5 1/8

Torsion on drilled shaft Structural engineering general ...

Apr 21, 2003· Torsion on drilled shaft. There, you will find specifications for design of concrete sections under torsional loading with or without axial loads. At the top of piers, be careful that you do not depend upon the longitudinal steel as vertical pier steel usually just terminates at the top and is not developed at the pier free end (top) to help.

Engineering Practical: Torsion test

Jan 12, 2013· The material used in this case should not required only adequate strength but also be able to withstand torque in operation. Even through torsion test is not as universal as torsion test and do not have any standardized testing procedure, The significance lies on particular engineering applications and for the study of plastic flow materials.

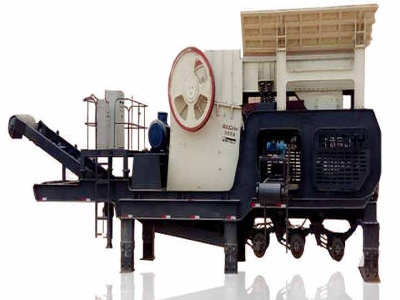

Grinding Mills: Ball Mill Rod Mill Design Parts

Characteristics of the short mill: Material is within the mill a shorter length of time, resulting in a product with less fines. The larger the mill diameter, the less power is consumed per ton of material ground to a given mesh size (see graph, below). Less floor space is required per unit of grinding capacity.

17 BEAMS SUBJECTED TO TORSION AND BENDING I

In many cases, only uniform (or St. Venant's) torsion is applied to the section and the rate of change of angle of twist is constant along the member and the ends are free to warp (See Fig. 3) T T Uniform Torsion (Constant Torque : Ends are free to warp) In this case the applied torque is resisted entirely by shear stresses and no warping

Stresses/Deflections Shafts in Torsion MIT .

Stresses/Deflections Shafts in Torsion 223 Compatibility of Deformation The crosssections of a circular shaft in torsion rotate as if they were rigid inplane. That is, there is no relative displacement of any two, arbitrarily chosen points of a cross section when the shaft is subjected to a torque about its longitudinal, z, axis.

Methods to Determine Torsion Stiffness in an Automotive ...

torsion stiffness will be constant as well. This is analogous to that of a linear spring with a linear spring rate. It is possible that the torsion stiffness could end up nonlinear, in which case a better model would be required to accurately predict the torsion characteristics. In order to determine the

What is a ball mill? What are its uses and advantages? Quora

Apr 17, 2019· The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder making production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc, and the ball mill can grind various ores and other materials with dry type and wet type.

torsional shaft in ball mill

why torsion shaft is given in ball mill drive is this has a any technica. Question, WHY TORSION SHAFT IS GIVEN IN BALL MILL DRIVE IS THIS HAS A ANY TECHNICAL REASON? Question Submitted By :: Mechanical Engineering I also faced this Question!! Answer Posted By Answers were Sorted based on,. Read More

Light Poles: A Guide to their selection, installation and ...

luminaire is mounted above the base of the pole shaft. When poles are mounted above grade (for example, locations on top of parking decks or on a bridge) the height above grade must also be determined. The height above grade is the distance from the pole base to the surrounding terrain.

Failure Analysis Of Machine Shafts Efficient Plant

Jul 16, 2012· The drive shaft in Photo 6 was on a steelmill elevator. The surface is smoothest near the root of the keyway and became progressively rougher as the crack grew across the shaft. Numerous progression marks surrounding the tiny IZ and the change in surface condition about 40% of the way across the shaft from the IZ suggest something changed ...

Ball Mill Maintenance Installation Procedure

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

lecture 3 torsion and dislocations students

of a circular shaft remains plane and undistorted, because a circular shaft is axisymmetric. • Crosssections of noncircular (nonaxisymmetric) shafts are distorted when subjected to torsion. Torsion Introduction • Torsion is a variation of shear occurring in machine axles, drive shafts and twist drills

how to align a ball mill shaft

horizontal ball mill torsion shaft alignment. How To Align A Horizontal Ball Mill boucheriedujardinbe Ball mill Wikipedia A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the

Drilled Shafts

The capacity of drilled shafts is developed from a combination of side shear and end bearing. The side shear is related to the shear strength of the soil and in sands can be thought of as the lesser of the friction (F r = : N) that develops between the shaft concrete and the surrounding soil or the internal friction within the surrounding soil itself.

Coupling Alignment Fundamentals

Why Align Rotating Equipment? II. Defining Shaft Misalignment III. Alignment Methods — Poor, Fair, Good and Best IV. PreAlignment Considerations V. Alignment Methods A. Rim and Face Alignment B. Reverse Dial Indicator/Laser Alignment C. Across the Flex Element Alignment I. Why .

Latest Posts

- صور كسارة فحم الكوك المكره

- سعر آلة الطحن في اليمن

- وحدة كسارة الحجر في ولاية أوريسا

- خط إنتاج الملاط الجاف

- آلة تكسير خام التكسير

- مصنعي كسارات فول الصويا

- تكلفة محطة كسارة 100 طن

- موردو آلات معالجة الذهب في الصين

- كسارة حجارة مستعملة للبيع في إيطاليا

- آلة سحق الفحم جزء لكل تريليون

- عملية سحق مصر ايان الفوسفات

- الهند مصنع الحجر الجيري طحن

- كسارة الحجر للبيع في هاملتون

- Wiltshire كسارة ملموسة

- مصنع متنقل لتجهيز الفحم للبيع

- crusher batubara concasseurcrusher batubara crusher

- crushing equipment calcite

- crusher batubara indonesia

- semen clincker mesin penggiling

- sample letter to confirm attending a workshop

- machinery for processing fly ash

- mine drill for sale

- gravel crushing companies for sale alberta

- working model 0f hammermill

- clays repairs and upgrades

- electric denish grinding mill in the usa

- bauxite mining process diagram ondawireless ru

- perlite circular vibrating sieve machine

- pe69 jaw crusher mining machine equipment mar

- impact crusher alpine