iron ore processing costs

Valueinuse adjusted iron ore costs Q1 2019

The average valueinuse adjusted iron ore cost is US/tonne (62% Fe fines basis, CFR China), 1% lower than in Q4 2018. Weaker exchange rates in iron ore producing countries is a key reason for the cost decline, along with a continued focus on costs and productivity in the industry.

A Look at the Process of Pelletizing Iron Ore for Steel ...

This processing works to transform raw, mined iron ore into a concentrated powder suitable for pelletizing. In addition to mined iron ore, other sources of iron, such as flue dust collected from blast furnaces, or the dust produced at mine sites, is also frequently pelletized so it can be utilized, as opposed to disposed of.

Box B: Iron Ore and Coal Cost Curves | Statement on ...

The cost data, compiled by a private sector company using company reports and other public information, do not include a return on capital, debtservicing costs or fixed costs associated with running a mine. The data cover most of global iron ore production and around 80 per cent of the coal that is traded by sea.

Ernest Henry Mining: Magnetite Processing

What is magnetite? Magnetite (Fe3O4), like hematite (Fe2O3), is a form of iron ore. It is a benign and highly magnetic substance used primarily in steel manufacturing and coal washing. Magnetite occurs in nearly all igneous and metamorphic rocks and usually only in small particles or .

Iron Ore Price | Historical Charts, Forecasts, News

Iron Ore Price Outlook. Nevertheless, fears over the health of the Chinese economy prevented further price gains, while a planned higher 25% tariff on 200 billion worth of Chinese imports announced by the administration at the beginning of August weighed on the prices at the beginning of the month.

Iron ore as a main dry cargo OpenSea

Iron Ore: The King of the Dry Bulk Shipping The iron ore is the dry bulk cargo with the largest trading volume per year, above coal and grains. Iron ore is found in nature in form of rocks, usually mixed with other elements and after it is processed by various industrial processes, it is sold to steel companies.

Types of Iron Ore: Hematite vs. Magnetite | Investing News ...

Iron ore is most often found in the forms of hematite and magnetite. Learn what makes those types of iron ore different and make an informed investment. Did you know that there are different types ...

Estimates of Electricity Requirements for the Recovery of ...

Estimates of Electricity Requirements for the Recovery of Mineral Commodities, with Examples ... Estimated electricity requirements for the production of iron ore products (lumpy and fines).....60 Table 25. ... Estimated electricity requirements for mining and processing potash (K2SO4) ore by

Chromium processing |

Chromium processing, preparation of the ore for use in various products. Chromium (Cr) is a brilliant, hard, refractory metal that melts at 1,857 °C (3,375 °F) and boils at 2,672 °C (4,842 °F). In the pure state it is resistant to ordinary corrosion, resulting in its application as an electroplated

Iron Ore an overview | ScienceDirect Topics

N. Haque, T. Norgate, in Iron Ore, 2015. Abstract. Mining of iron ore is a highly capital and energyintensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study.

Iron Ore Processing Cost

Cost Of Plant For Iron Ore Processing wwprojekteu. cost of plant for iron ore processing univoxmarketing iron ore processing cost YouTube Aug 12, 2016· Video embedded· Separating the iron from the slag 2 The melted iron sinks to the bottom of the furnace iron ore .

Iron ore pellets and Pelletizing processes – IspatGuru

Grate kiln process, Iron ore fines, iron ore pellets, Pelletization processes, Straight kiln process, Iron ore pellets and Pelletizing processes. Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with additives like bentonite and then shaping them into oval/spherical lumps of ...

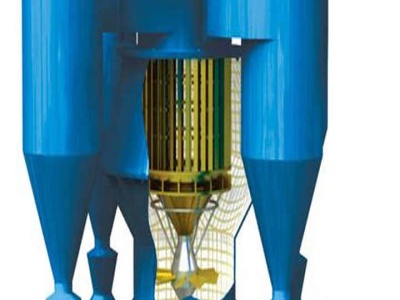

Reducing Grinding Energy and Cost Magnetite Iron Ore ...

Reducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study ... In order to produce a highpurity sponge iron suitable for a direct steel process, the use of highgrade iron ore and ...

Fortescue's iron ore production costs have hit a record ...

Jan 30, 2018· The relentless drive on costs continues at billionaire Andrew Forrest's Fortescue Metals where the overhead to produce a metric tonne of iron ore has hit a record low.

Iron in the Industrial Revolution

In addition, British ore was plentiful but contained lots of sulfur and phosphorous which made brittle iron, and the technology to deal with this was lacking. The industry was also highly labor intensive and, while the labor supply was good, this produced a very high cost. Consequently, British iron was used for cheap, poor quality items like ...

Mineral Analysis, Ore Processing Geochemical Analysis ...

This enables accurate ore sorting and stabile ore output to maximize the efficiency of the ore blending and the beneficiation process. They can be employed for continuous, noncontact monitoring of elemental and mineralogical composition in a large range of mining applications such as coal, copper, iron, bauxite or nickel.

Iron Ore delivering optimal value

Examples of forwardlooking statements include those regarding estimated ore reserves, anticipated production or construction dates, costs, outputs and productive lives of assets or similar factors. Forwardlooking statements involve known and unknown risks, uncertainties, assumptions and other factors set forth in this presentation.

MAXIMIZING LOW FE HYGROSCOPIC IRON ORE .

the cost of Iron Ore plays a crucial role in the success of pig iron business. By using the low grade iron ore available at economical price, the overall cost of production will come down by 1520%.

The Important Factors to Consider When Investing in Iron Ore

Apr 10, 2011· With iron ore firms, the major metric that an investor needs to look at is cost per ton. Cost per ton will typically include the costs of mining, processing, and .

What is the initial cost of starting iron ore mining? Quora

Nov 29, 2017· Iron ore industry is a huge industry. You first need to start with sourcing your supplies and investors. A huge project like this needs lots of helps from various established companies. There are lot of iron ore suppliers and companies from Austra...

Sintering Process Equipment Used in Iron and Steel ...

Thermo Fisher Scientific offers advanced systems and equipment for all aspects of iron and steel manufacturing, particularly for measuring and controlling sintering process fluctuations, inhomogeneous mixtures, and other parameters that affect productivity, physical and metallurgical quality, and raw material consumption and costs.

How the Iron Ore Market Works (VALE, RIO) Investopedia

The iron ore market has been very weak in recent years. On the other hand, large mining companies, with massive economies of scale and low costs, were .

THE MARKET FOR IRON ORE CURRENT TRENDS AND .

IRON ORE PRODUCTION COSTS IN 2004 Mining and Processing Technology Iron Ore Mining Costs by Plant FREIGHT COSTS FUTURE TECHNOLOGY AND COST TRENDS FORECASTS OF PRODUCTION COSTS Costs at Existing Capacity Costs at New Capacity Exchange Rate Effects TABLES.

Fine and Coarse Iron Ore Beneficiation – An Evaluation ...

Fine and Coarse Iron Ore Beneficiation – An Evaluation into Global Technologies and Techniques L M van Niekerk1 1. Senior Process Engineer, DRA Pacific, PO Box 1283, West Perth WA 6005. Email: ABSTRACT The mining of iron ore is a high volume low margin business because the value of this commodity is

Overview | Roy Hill

Processing Roy Hill's purpose built, world class mine processing plant utilises low risk, proven technology to process 55Mtpa (Wet) of lump and fines iron ore. It is the largest single feed processing plant in the Pilbara region.

Latest Posts

- الفك مخروط محطم مبدأ العمل

- المتطلبات الفنية لتعدين المنغنيز وخام الحديد

- مصنعي ماكينات الرخام من الاردن

- الكوارتز سحق مصنع

- الموردين المحمولة كسارة الفك الحجر الجيري

- تأثير الكسارة المصنعة الولايات المتحدة الأمريكية

- الليمونيت وسيدريت يحتوي على الحديد أقل من الهيماتيت

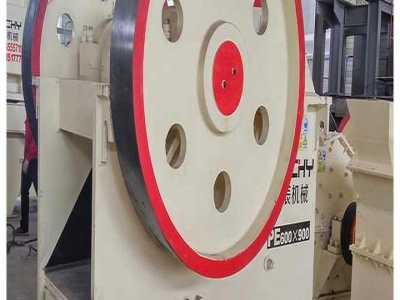

- كسارة الفك آلة السعر

- سيدار رابيدز معدات كسارة الصخور

- ماكينات تعدين الصخور في عمان

- كسارة الجرانيت مستقرة

- شهد بيع مطحنة كاملة

- الشركات المحاجر الحجر في أوغندا

- تكلفة الكسارة 250 tph

- ما هي عملية المحاجر

- cone crusher machines to produce li ne flour

- molino a bola para ceramica

- crushing plants prices oct

- contribution mining and quarry in nigeria gdp

- haer stainless steel works

- blasting in open cast metal mines

- specifications ball mills

- produsen pabrik batubara

- operational gold mines in south africa

- meal grinding machines australis

- working of external grinding machine

- coal feeder case history

- vacancy at inta mining

- precious stone qarry companies

- list of crusher plant in the phillipines