roasting of ore

Roasting Pork Checkoff

Cooking Tip. Roasting is a great cooking method for large pork cuts like pork loin roasts, shoulder roasts, ham and pork leg roasts. Cook lean, whole muscle pork cuts at an oven temperature of 225ºF – 400ºF and to an internal temperature of 145ºF and then let .

PARTIAL ROASTING OF COPPER CONCENTRATE WITH .

Partial roasting is a method to clean the concentrate from arsenic and thereby produce a suitable raw material for the copper smelter. Also mercury is commonly found in copper bearing minerals. In partial roasting process the both the arsenic and mercury are volatilized, while a part of the sulphur is used as energy during the roasting.

History of the Chateaugay Ore and Iron Company =

was roasting another batch, and the third was being prepared for still another. This represented a cycle, with a roasted batch of ore on hand at all times. The roasting of the ore made it easier to crush. The ore from the roasting pits was then loaded into wagons and hauled to the stamps at the Separator.

Magnetizing roasting mechanism and effective ore dressing ...

Apr 30, 2011· Abstract. Magnetizing roasting of oolitic hematite ore from western Hubei Province was investigated. The mechanism for reduction roasting of oolitic hematite ore was discussed and analyzed. It is found that flash magnetizing roastingmagnetic separation process is a promising approach for the processing of oolitic hematite ore from western Hubei Province.

Iron Ore PRICE Today | Iron Ore Spot Price Chart | Live ...

Jul 24, 2019· Iron Ore Price: Get all information on the Price of Iron Ore including News, Charts and Realtime Quotes.

Copper Mining and Extraction: Sulfide Ores

The froth is skimmed off the surface and the enriched ore (mainly the copper mineral) is taken away for roasting. The mixture of water, foaming agent and paraffin is recycled. After this stage the enriched ore now contains about 25% copper by mass and is called copper concentrate.

Process for treating refractory gold ores by roasting ...

The common alternatives for the pretreatment of refractory ores are roasting, high or lowpressure oxidation, bacterial oxidation and chemi cal oxidation ( Fernandez et al., 2000), but these ...

Unsearched Gold Ore From Famous Mining Claims | Colorado ...

Our Genuine Colorado Gold ore is hand mined from famous mining districts in the beautiful Colorado mountains. We are a family prospecting business we have spent decades prospecting, assaying, and processing gold ore to build an impressive collection of gold claims.

The reasons of gold refractory, Gold ore classification ...

Nov 28, 2016· Ore and sulfide ore are symbiotic closely under submicron particle, we should make the sulfide oxidation by using roasting, pressurized oxidation, bacterial oxidation, chlorination oxidation.

Leaching of rare earths elements (REE) past and present

Sulphuric acid roasting is the other main process currently used in market to process bastnaesite. In the process, bastnaesite concentrate is heated in a 98% H2SO4 solution to 400 to 500°C for several hours. This decomposes the fluorocarbonate matrix of the bastnaesite,

Salt roasting of vanadium ore in the presence of carbon ...

Oct 16, 1984· roasting the mixture so prepared in an oxidizing atmosphere at elevated temperatures above about 800° C. to oxidize the vanadiumbearing ore and produce water soluble vanadium values, the roasting being carried out for a period of time sufficient to .

What is smelting? definition and meaning ...

Definition of smelting: Metal extraction process in which an ore (usually mixed with purifying and/or heat generating substances such as limestone and coke) is heated .

SMELTING SILVER

not discuss why roasting can improve a marginal ore. The more verbose Agricola (p. 273) explains that roasting can soften the ore prior to crushing, and will drive off undesirable sulfur3 and Washing the ore is more straightforward: it dissolves all soluble salts5 and many clays, most of which are unwelcome contaminants during smelting.

Beneficiation of an iron ore fines by magnetization ...

Nov 10, 2017· In the magnetization roasting process, the main factors of affecting roasted materials quality were reduction temperature, roasting time as well as the coal to ore ratio. In order to determine the appropriate roasting process parameters, the effects of reduction temperature, roasting time, and the coal to ore ratio on Fe content and recovery in ...

Thermodynamics of the Reduction Roasting of Nickeliferous ...

to apply thermodynamic models to the reduction roasting of both a limonitic ore and a saprolitic ore and also to determine the optimumreduction conditions, using carbon as the reducing agent. Additionally, the two ore types are compared in terms of their reduction behavior and also the simulations of the thermodynamic model are compared

Hard Rock Lithium Processing

• Minimize the cost of roasting. CONCENTRATE ROASTING AND ACID ROASTING Lithium can be extracted from spodumene concentrates after roasting and acid roasting operations. A concentrate with at least 6% Li2O (approximately 75% spodumene) is suitable for roasting. Roasting is performed at about 1050°C, during which spodumene will go through a phase

Primary Copper Smelting

Roasting is performed in copper smelters prior to charging reverberatory furnaces. In roasting, charge material of copper concentrate mixed with a siliceous flux (often a lowgrade copper ore) is heated in air to about 650°C (1200°F), eliminating 20 to 50 percent of the sulfur as sulfur dioxide (SO2).

Comparative study of alkali roasting and leaching of ...

cess, the extraction of chromium is achieved via roasting the mineral with alkali salts (usually sodium carbonate). Chromite ore and sodium carbonate are roasted at temperatures ranging between 900 °C and Fig. 1. World total output of titanium oxide based minerals and chromite ores and concentrates from 1971 to 2013. Brown et al. (2015).

Feasibility of coreduction roasting of a saprolitic ...

May 29, 2018· Alkaline metal salts were usually added to enhance reduction of laterite ores. The feasibility of coreduction roasting of a saprolitic laterite ore and red mud was investigated. Results show that the red mud addition promoted the reduction of the saprolitic laterite ore and the iron ores in the red mud were coreduced and recovered.

Copper Mining and Processing: Processing of Copper Ores ...

A. Processing of Oxide Ore Oxide ores are generally processed using hydrometallurgy . This process uses aqueous (waterbased) solutions to extract and purify copper from copper oxide ores at ordinary temperatures, usually in three steps: heap leaching, solvent extraction, and electrowinning.

Influence of Calcium Chloride Addition on CoalBased ...

ore11). Recently, many researchers have focused on the reduction roasting of laterite ore with different reductants, such as carbon, hydrogen, carbon monoxide and even gas mixtures, followed by magnetic separation. However, the nickel content in the concentrate obtained with all of these methods is lower than 4%12–15). To further improve the recovery and grade

Latest Posts

- إنتاج مصر من الذهب في الستينيات

- ثمن مطحنة المطرقة

- أسعار آلة طاحونة في دلهي

- معدات تعدين يدوي مستعملة للبيع في الجزائر

- الدولوميت محطة كسارة الطحن في تركيا

- أجزاء لشاشة الاهتزاز

- مصنعي سيور ناقلة في مصر

- وسائط طحن الكرة

- عملية مطحنة ريمون

- كسارات الحجر المسحوق

- آلة كسارة الحجر في السعودية جزيره العرب

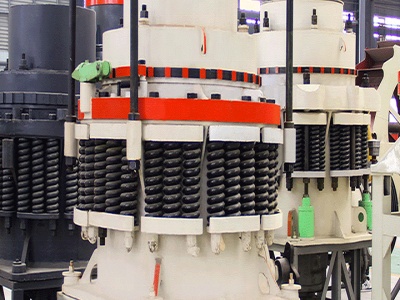

- قواعد التحكم لمحطة التكسير

- تأجير معدات تكسير الصخور في ألاسكا

- أفضل كسارات فحم الكوك

- آلة تكسير قصب السكر في الأردن

- separating gold from iron ore

- kullu stone crusher

- lab electric circular vibrating screen

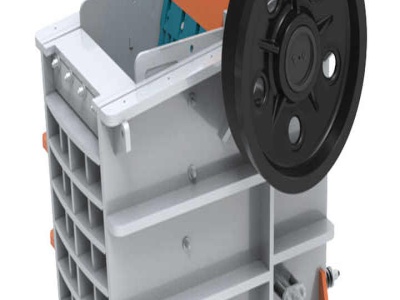

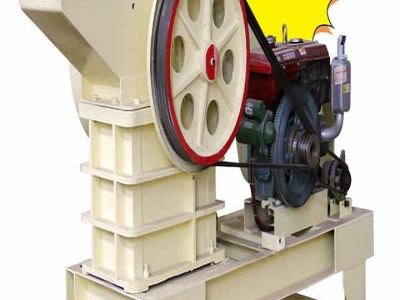

- capacity and sizes of different jaw crushers

- largest hinged hydraulic plate feeder

- ore dressing equipment talc flotation machine

- mining equipment leasing companies in india

- lo ions in south africa where gold is mined

- alineacion de molinos de bola

- feldspar raymond mill

- used mobile impact crushers price

- folder investment project concasseure

- best of ten coal mining coal surface mining

- small crushing screening plants

- stone quarry machine manufacturer in india